Culture apparatus and applications thereof in cell culture

A culture device and cell technology, applied in tissue cell/virus culture devices, biochemical instruments, biochemical equipment and methods, etc., can solve the problem of low oxygen dissolution efficiency, lack of cell culture attachment and growth, and expansion of unfavorable culture volume Process control and other issues to achieve the effect of avoiding pollution and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

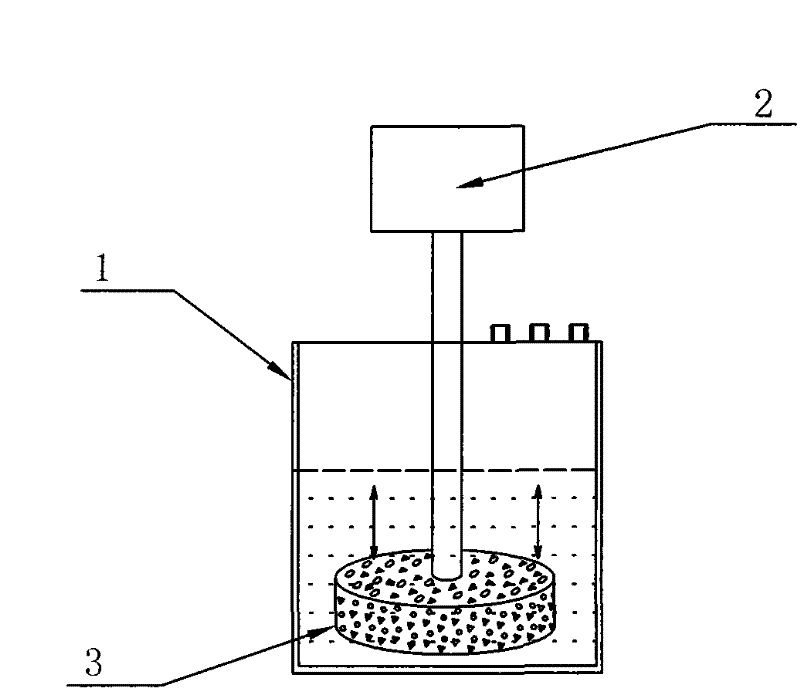

[0036] Embodiment 1, as figure 1 As shown: the transmission device 2 enables the carrier module 3 to gradually change from fully exposed to the gas above the liquid surface to fully immersed in the culture solution in the airtight container 1, and then gradually change from fully immersed in the culture solution to fully exposed to the gas In this way, it moves back and forth again and again, and the movement method is up and down piston movement.

Embodiment 2

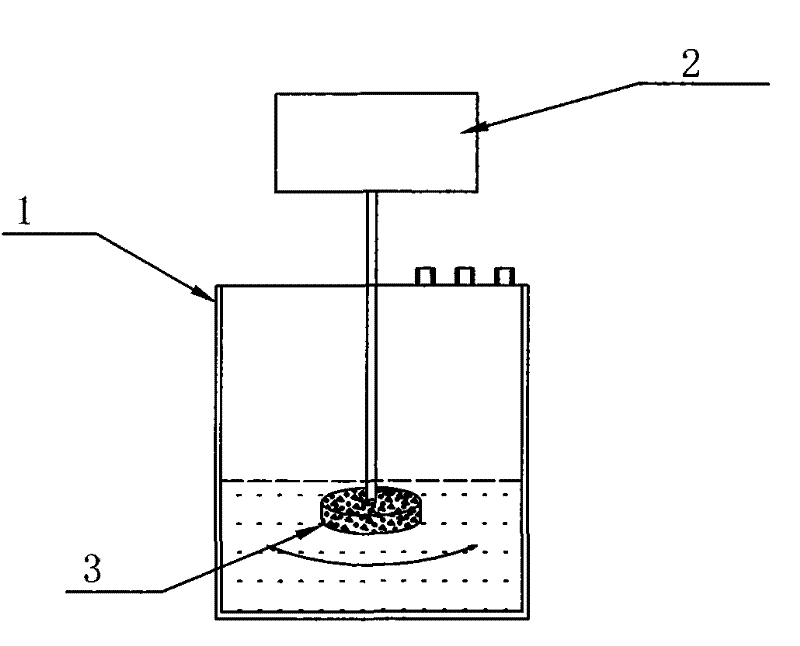

[0037] Embodiment 2, as figure 2 As shown: the transmission device 2 enables the carrier module 3 to gradually change from fully exposed to the gas above the liquid surface to fully immersed in the culture solution in the airtight container 1, and then gradually change from fully immersed in the culture solution to fully exposed to the gas In this way, it moves back and forth again and again, and the movement method can be a pendulum movement.

Embodiment 3

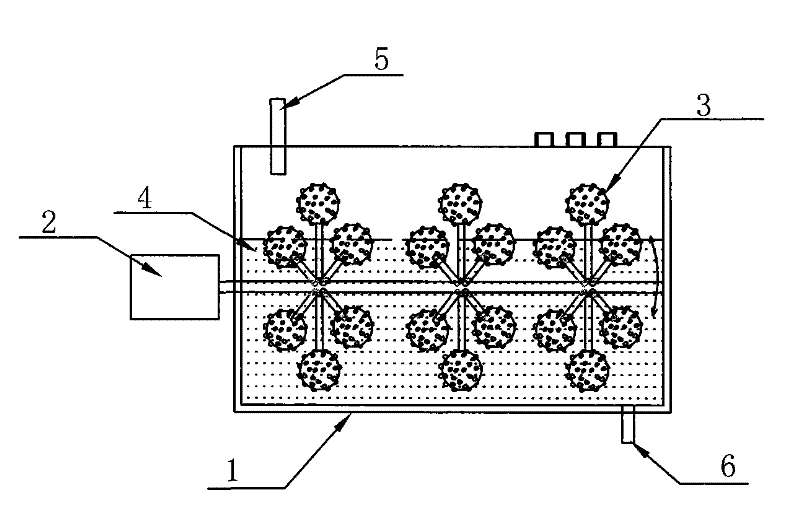

[0038] Embodiment 3, as indicated image 3 As shown, a plurality of carrier modules 3 are distributed on the transmission device at a certain distance. When the transmission device 1 drives the carrier module 3 to move in the airtight container 1, part of the carrier module is exposed to the air, while the other part is immersed in the culture solution 4. With the movement of the transmission device, the exposed carrier part is gradually immersed in the In the culture solution, the other part submerged in the culture solution is gradually exposed to the air, so that the carrier module moves periodically in the gas or in the culture solution. The airtight container 1 is provided with a liquid inlet 5 and a liquid outlet 6 .

[0039] After a large number of experiments, it has been proved that the maximum cell number and state of the cells harvested by this equipment can meet the actual needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com