Application of bacillus licheniformis alkali protease as asymmetrical direct Aldol reaction catalyst

A technology of Bacillus licheniformis and protease, which is applied in the direction of fermentation to achieve the effects of environmental friendliness, good application prospects and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0019] The Bacillus licheniformis alkaline protease (EC 3.4.21.14) used in the preferred embodiment is derived from Bacillus licheniformis 2709, purchased from Wuxi Xuemei Enzyme Technology Co., Ltd., with an enzyme activity of 200 U / mg.

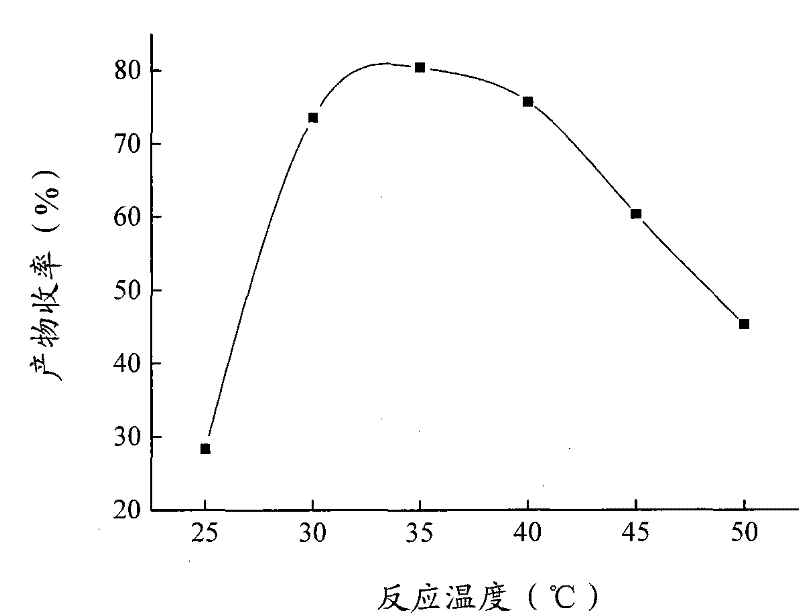

[0020] 1. Condition optimization of the asymmetric direct Aldol reaction catalyzed by Bacillus licheniformis alkaline protease

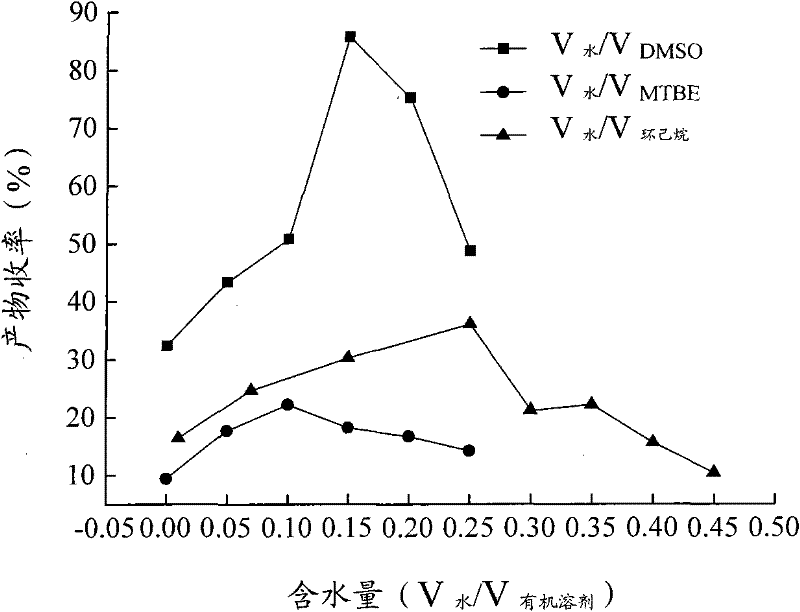

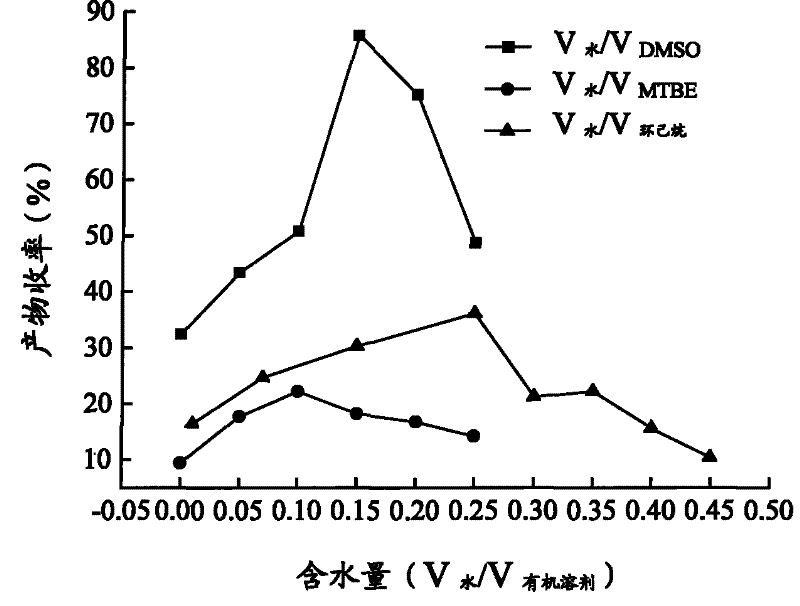

[0021] (1) Optimization of organic solvents

[0022] The present invention takes the reaction of acetone and p-cyanobenzaldehyde as a model reaction, and investigates the organic solvent of the asymmetric direct Aldol reaction catalyzed by bacillus licheniformis alkaline protease.

[0023] The method is as follows: add bacillus licheniformis alkaline protease (200mg), organic solvent (5ml), p-cyanobenzaldehyde (200mg, 1.5mmol) and deionized water (0.75ml) in the round bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com