Prefabricated reinforced concrete energy-saving outer-wall hanging plate as well as production technique and equipment thereof

A reinforced concrete slab and reinforced concrete technology, which is applied to clay preparation devices, walls, mixing operation control, etc., can solve the problems of slow building construction and low thermal insulation performance of building walls, and achieves fast masonry construction and improved construction. The effect of improving speed and thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

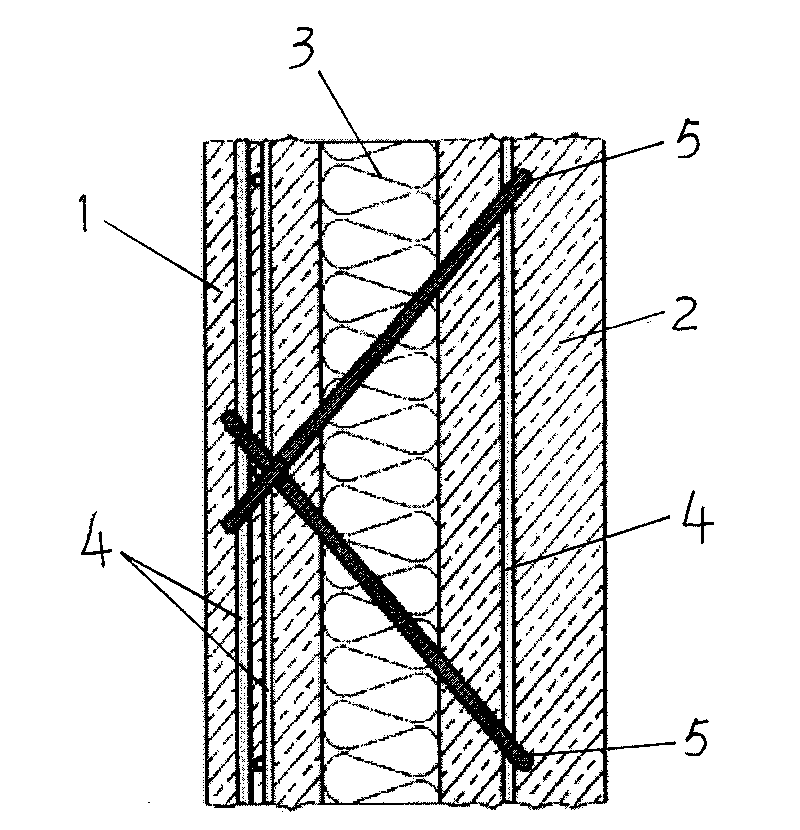

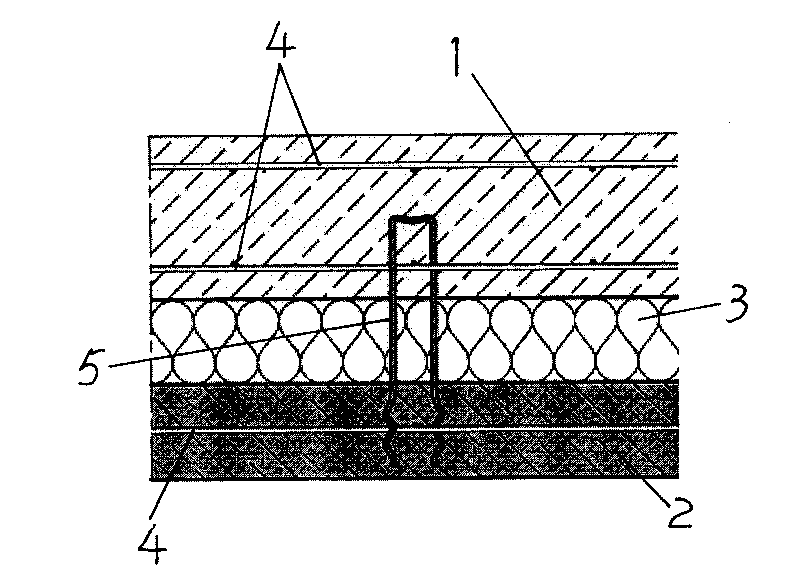

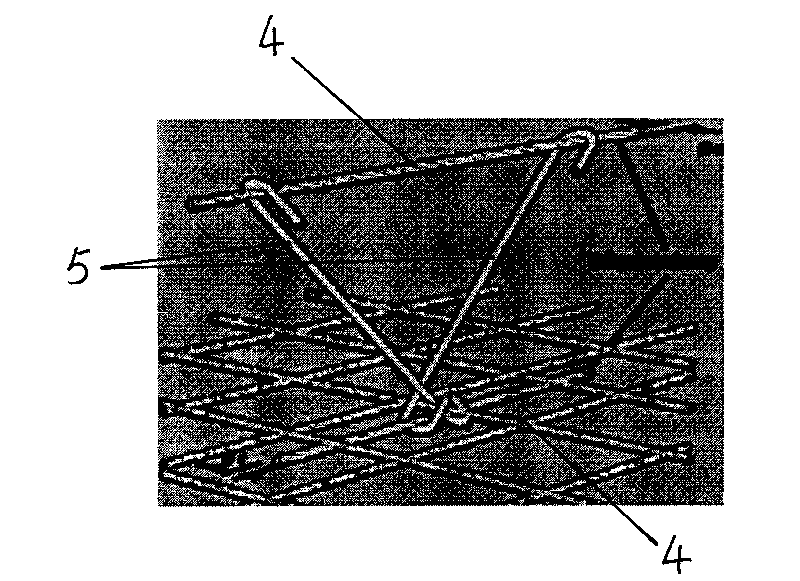

[0032] see figure 1 , figure 2 As shown, it is an embodiment of the prefabricated reinforced concrete energy-saving exterior wall hanging board of the present invention, which is composed of an insulating interlayer 3 sandwiched between the left reinforced concrete slab 1 and the right reinforced concrete slab 2, and the material of the insulating interlayer 3 is Benzene board or rock wool for heat preservation, steel mesh 4 is set in the left reinforced concrete slab 1 and right reinforced concrete slab 2, the steel mesh 4 in the left reinforced concrete slab 1 and the steel mesh in the right reinforced concrete slab 2 Pulling between 4 is provided with coupling piece 5, as image 3 and Figure 4 As shown, the coupling 5 includes oblique couplings and straight couplings, such as Figure 5 to Figure 10 shown.

[0033] The outer surface of the reinforced concrete slab on one side is pasted with a decorative plate or polished.

[0034] refer to Figure 11 , Figure 12 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com