Novel underground wet blasting machine of coal mine

A wet blasting machine, coal mine technology, applied in shaft lining, underground chambers, mining equipment, etc., can solve intermittent problems, achieve the effect of easy cleaning, prevent flying, and facilitate cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

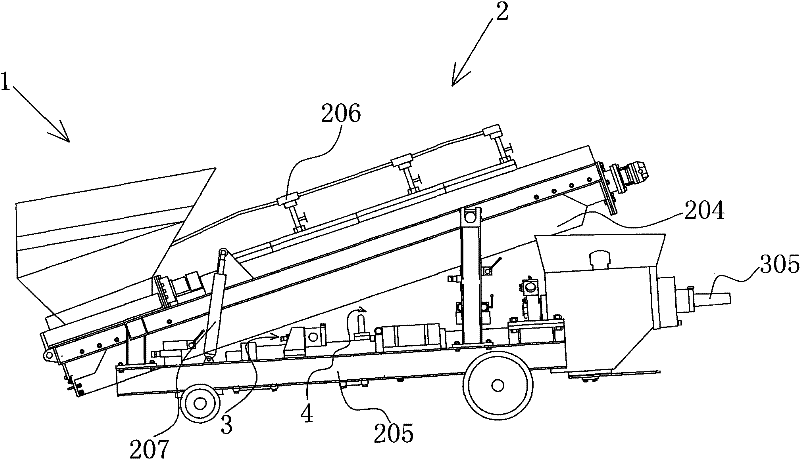

[0037] combine Figure 1 to Figure 8 , A new coal mine underground wet spraying machine, including batching mechanism 1, mixing mechanism 2, pumping mechanism 3 and injection mechanism, batching mechanism 1, mixing mechanism 2, pumping mechanism 3, and injection mechanism are connected in sequence. The batching mechanism 1 is a mechanism for mixing raw materials. The stirring mechanism 2 includes a helical stirring shaft 201. The helical stirring shaft 201 is provided with a helical pushing blade 202 and a stirring blade 203. The pumping mechanism pushes the concrete to the spraying mechanism, and the spraying mechanism will After the concrete and liquid quick-setting agent are mixed, the concrete is sprayed out under the action of compressed air.

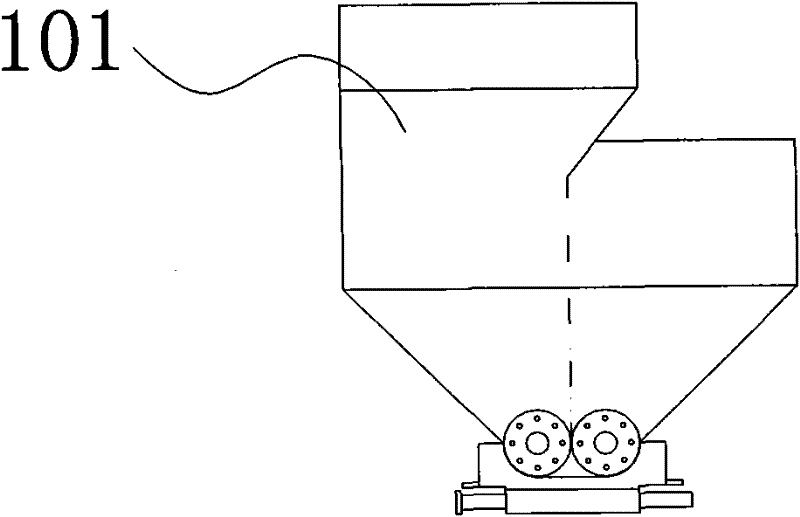

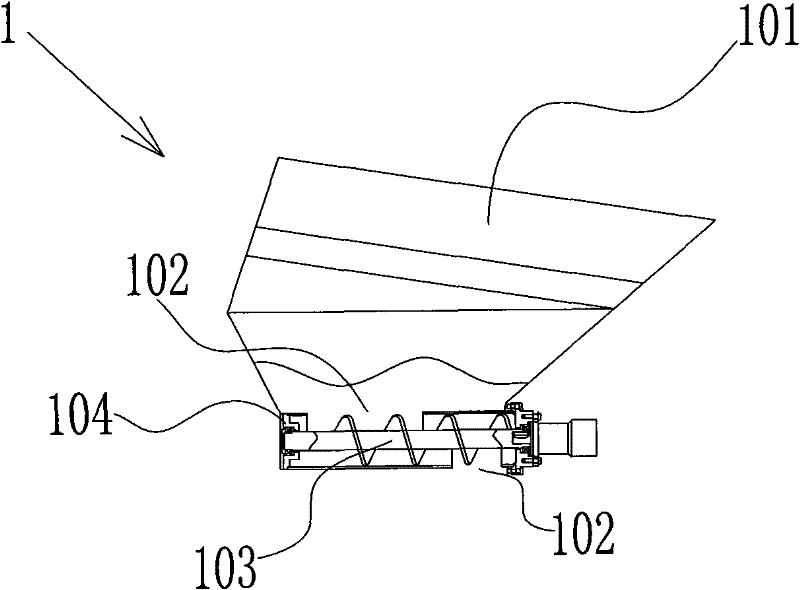

[0038] The batching mechanism 1 includes two batching hoppers 101 , each batching hopper 101 is provided with a screen at its upper part, and at its lower part there are two discharge ports 102 arranged in dislocation, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com