Lubricating method and lubricating structure of four-stroke gasoline engine

A lubrication structure, gasoline engine technology, applied in closed-circuit lubrication systems, mechanical equipment, engine components, etc., can solve the problems of high cost, many steps, low reliability, etc., and achieve the effect of fewer parts, simple steps, and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

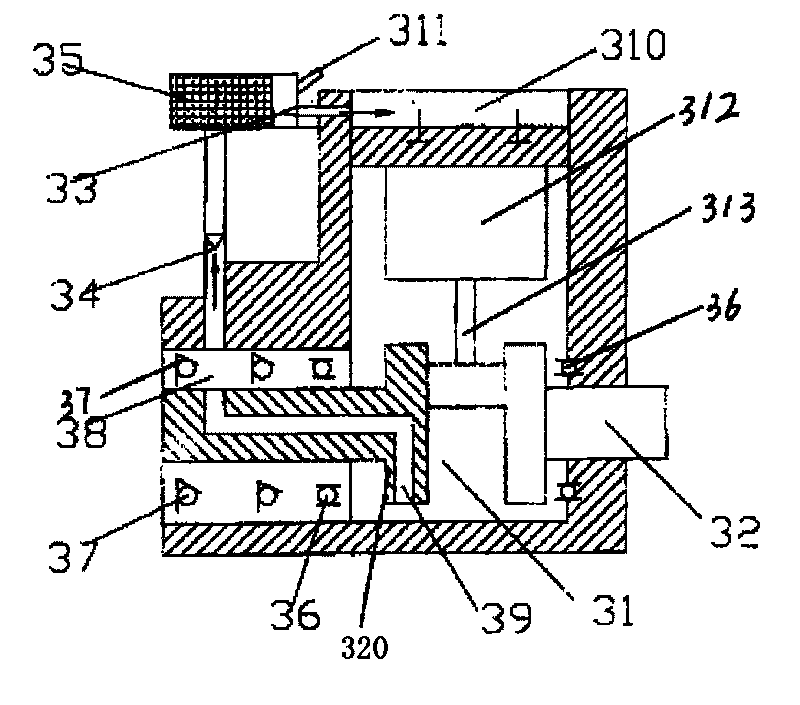

[0033] In order to be able to understand the technical means of the present invention more clearly, it can be implemented according to the contents of the description, and in order to make the above content and other purposes, features and advantages of the present invention more obvious and understandable, a preferred embodiment is specifically cited, and With accompanying drawings, the detailed description is as follows.

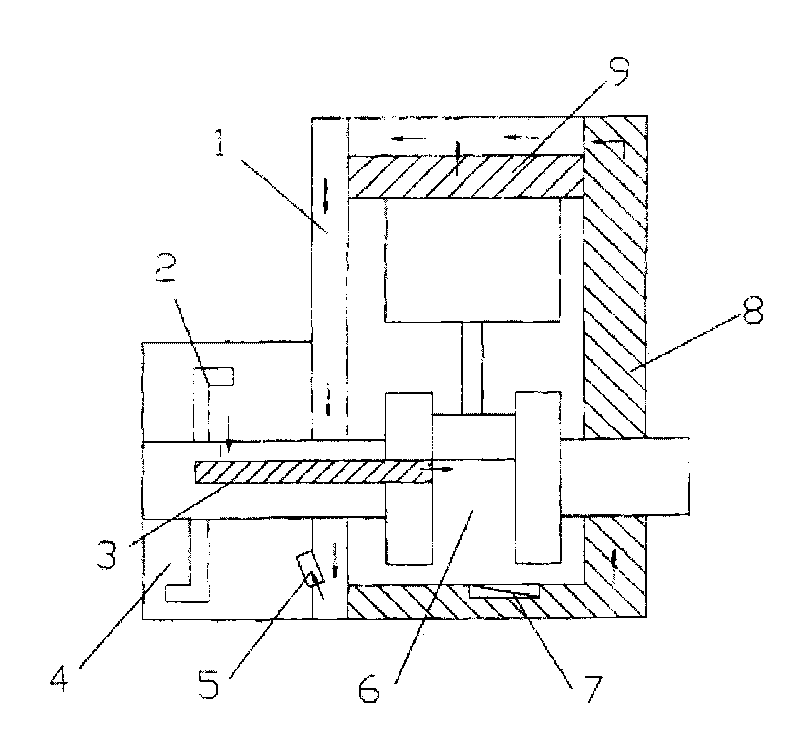

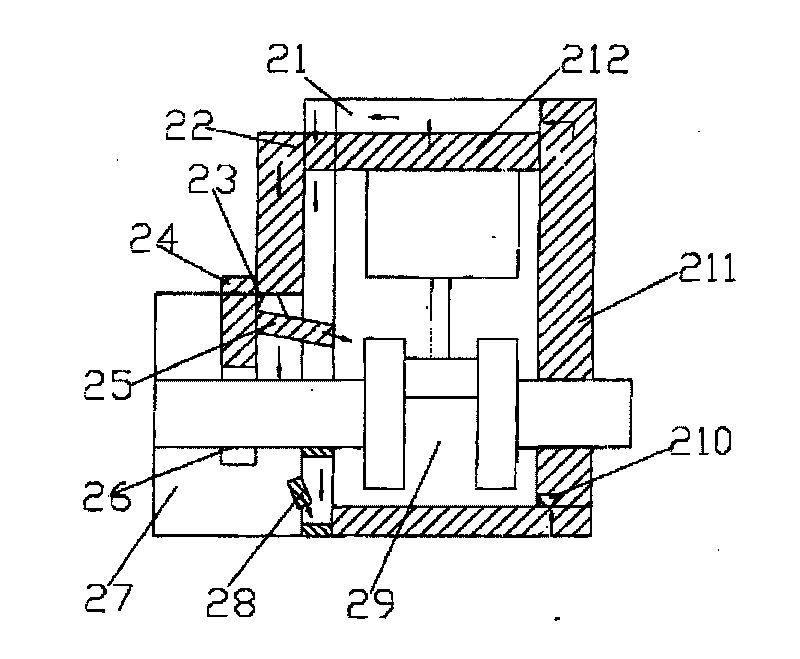

[0034] like image 3As shown, the lubricating method of the four-stroke gasoline engine of the present invention mainly includes two steps of crushing of lubricating oil, atomization and lubricating action of oil mist. The pressure causes the lubricating oil in the crankcase chamber 31 to splash, and the splashed lubricating oil is broken under the motion of the crankshaft 32 and its mechanism; when the piston 312 descends again, the pressure generated prompts the broken lubricating oil to atomize rapidly , when the pressure in the crankcase chamber 31 ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com