Gear case of adjustable propeller

A gear box and propeller technology, applied in the direction of belt/chain/gear, mechanical gear transmission, non-mechanical gear transmission, etc., can solve the problems of no accumulator, reduced clutch transmission capacity, power loss, etc., to meet the needs of use. requirements, reduce power loss, overcome the effect of stripping phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

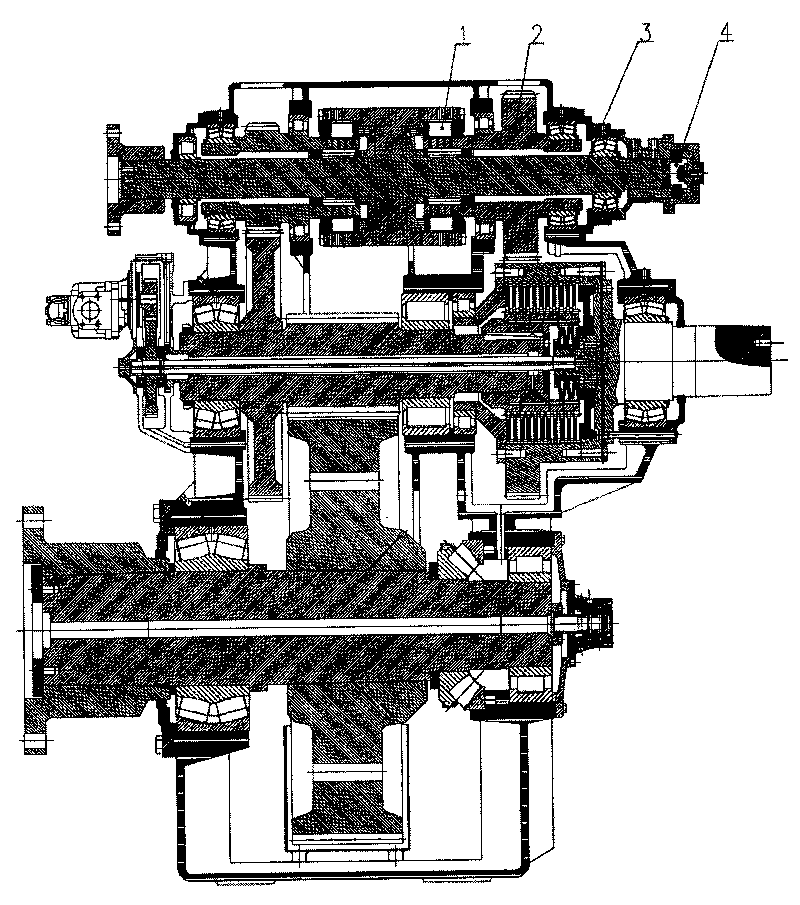

[0016] refer to figure 1 , equipped with an adjustable propeller gearbox, equipped with a PTO device, that is, an auxiliary power output device, and the PTO device includes a PTO clutch, a PTO gear, a PTO shaft and a hydraulic system.

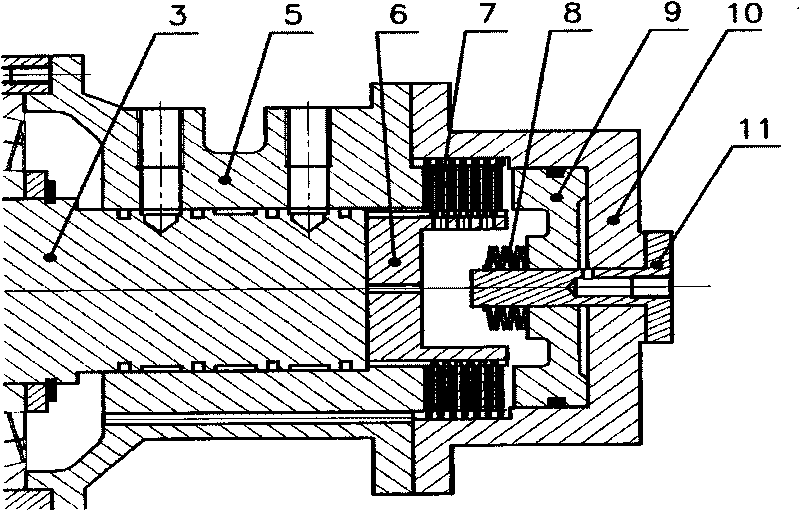

[0017] refer to figure 2 , the hydraulic brake device 4 includes a friction plate seat 6, an inner and outer friction plate 7, a piston 9, a butterfly spring 8, a hydraulic brake housing 10 and an oil distributor 11, and the hydraulic brake housing 10 is arranged on the PTO shaft end cover 5, the outer friction plate is connected to the inner surface of the hydraulic brake housing 10, the inner friction plate is set on the friction plate seat 6, and the friction plate seat 6 is set on the end of the PTO shaft 3, the said The oil distributor 11 is arranged on the hydraulic brake housing 10, and the piston 9 is slidably arranged in the hydraulic brake housing 10, and the working oil flows through the oil distributor 11 to push the piston to wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com