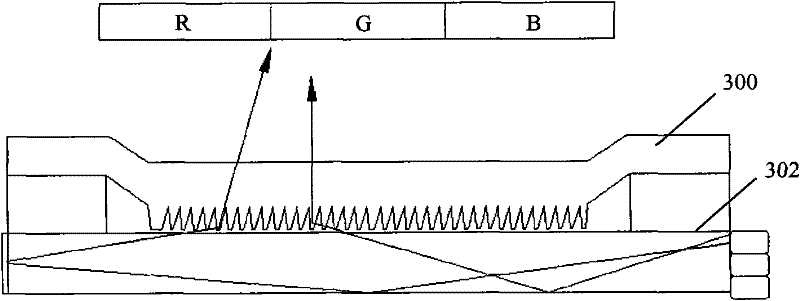

Light emitting diode (LED) backlight structure

A technology of backlight structure and light source, applied in the directions of optics, light guide, light source, etc., can solve the problems of insufficient partition, uneven image boundary, pixel correspondence, etc., and achieve the effect of eliminating unevenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0017] Before describing the specific implementation of the present invention, the TMOS technology is briefly introduced. The full name of TMOS technology is time-sequential multiplexing optical shutter technology, in which time-sequential multiplexing is an image formation method of a display. For a full-color image, red light, green light and blue light are injected sequentially, and the MEMS switch determines which color light will be transmitted at what time. In this sense, sequential multiplexing in TMOS technology is also the field sequential color generation process. It is not difficult to see that this method of sequential multiplexing is fully compatible with the construction basis in the existing technology, and does not require the manufacturer to rebuild the production workshop. In addition, it also gets rid of the filters required...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com