Waste heat exchange device for textile setting machine

A technology of heat exchange device and setting machine, which is applied in the processing of textile material equipment configuration, indirect heat exchanger, lighting and heating equipment, etc., which can solve the problems of inconsistent quality and performance, inconvenient maintenance, low heat transfer efficiency, etc., and achieve improvement Heat exchange effect and service life, effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

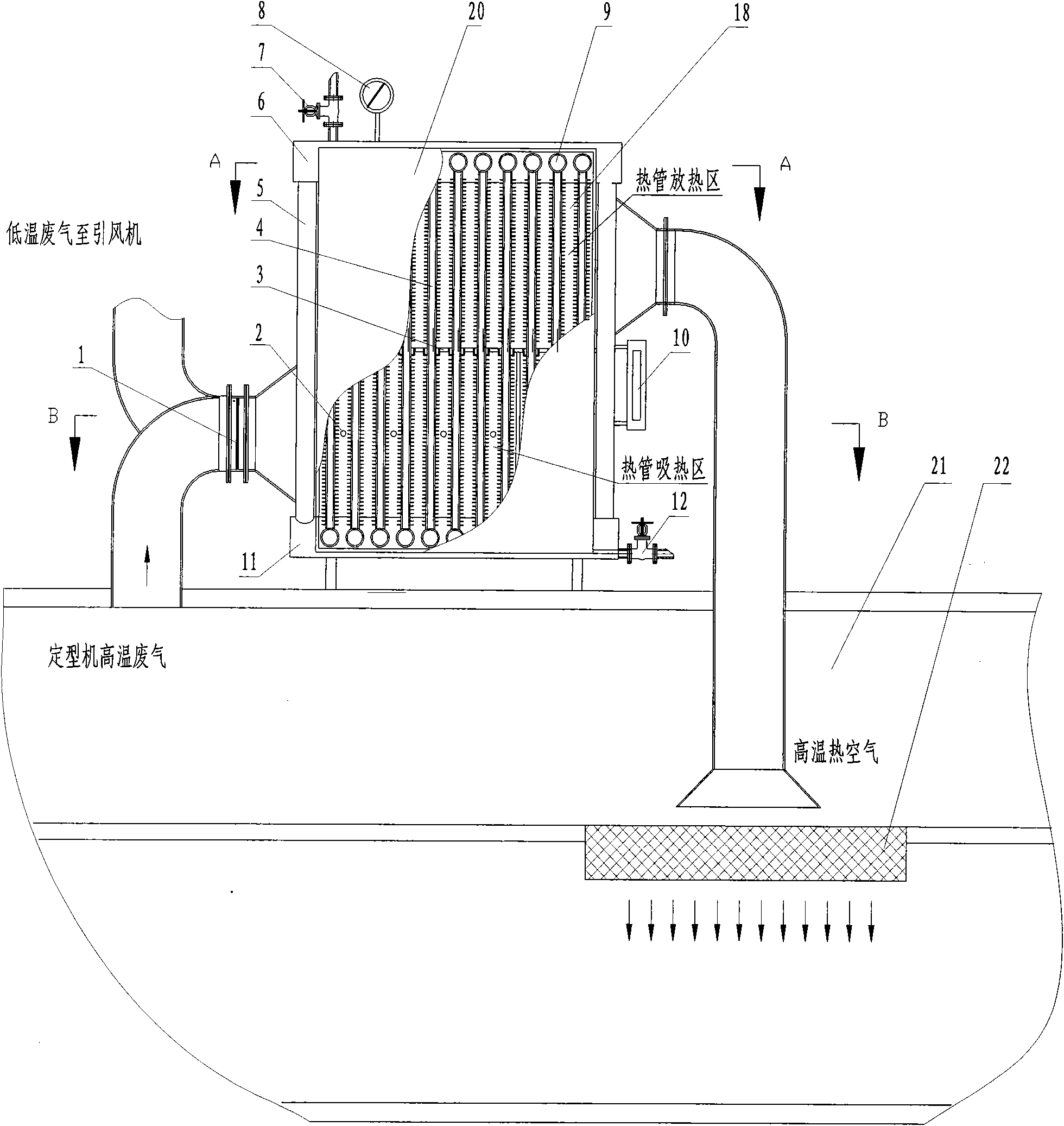

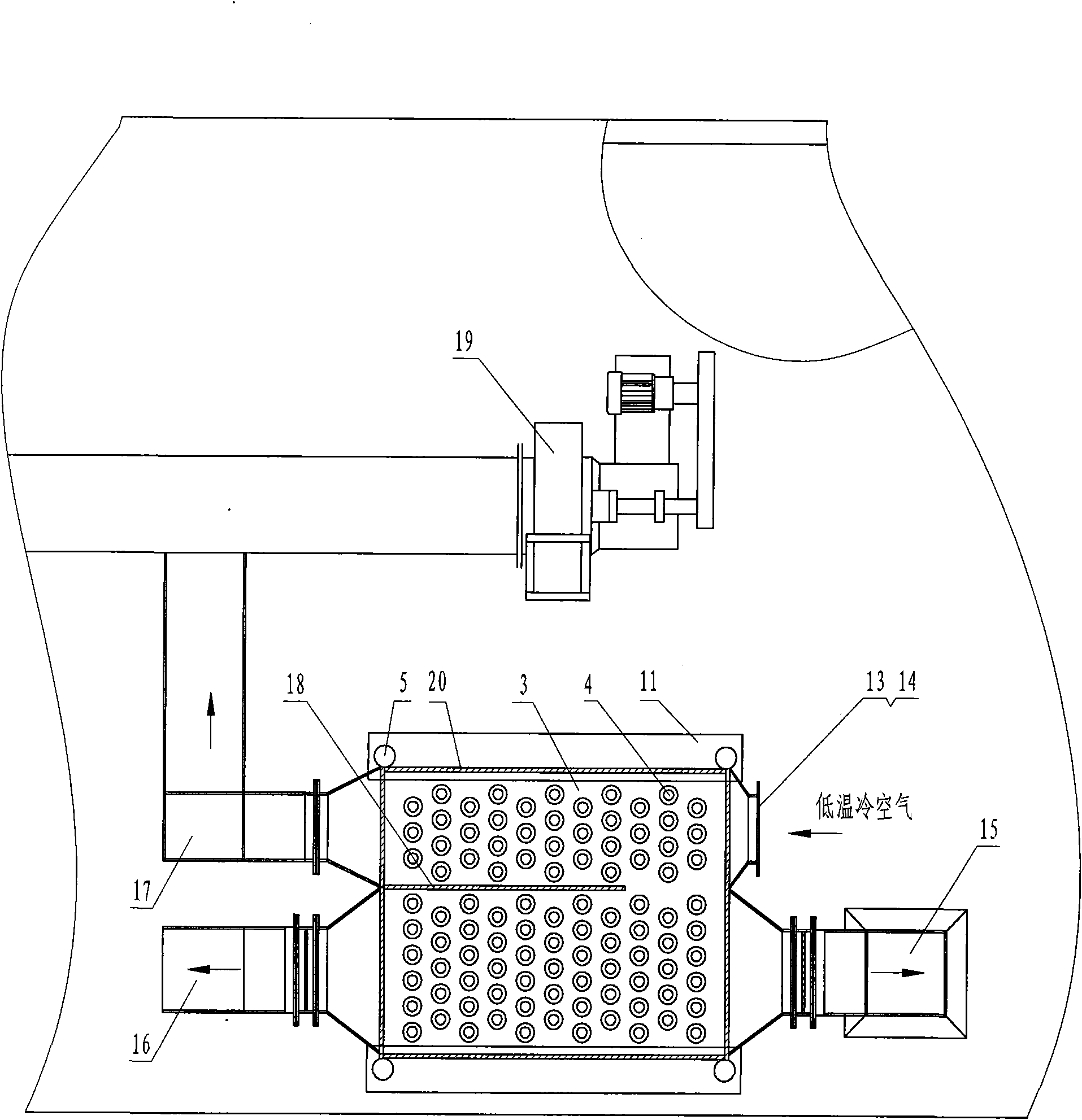

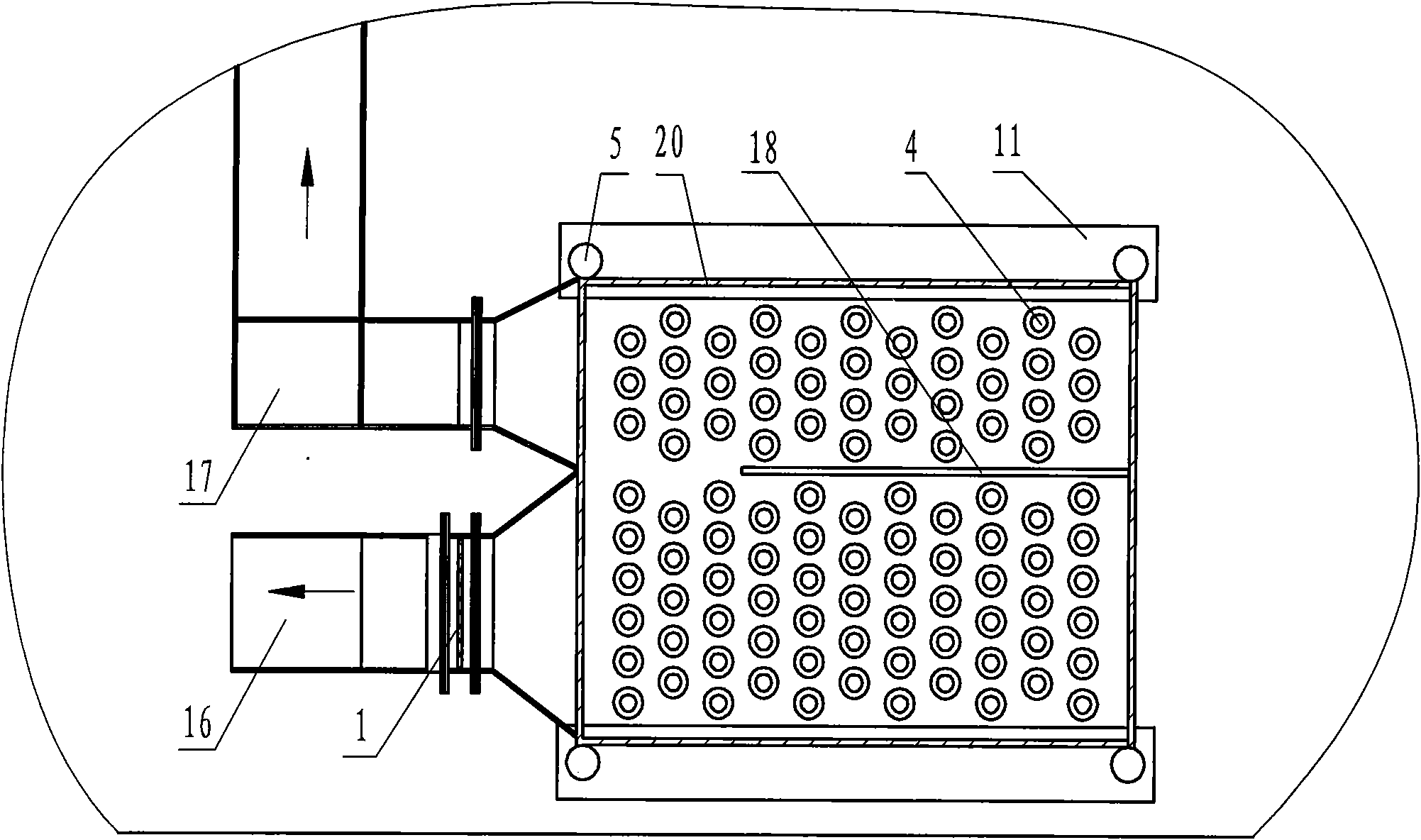

[0045] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0046] A waste heat heat exchange device for a textile setting machine, comprising finned heat pipes 4, a plurality of finned heat pipes 4 are vertically arranged, and the upper and lower ends are connected to header connecting pipes 9 arranged horizontally to form a rectangular heat transfer row;

[0047] Multiple rows of heat transfer rows are arranged in parallel, and the left and right sides of the upper and lower parts are respectively connected by two vertically arranged upper headers 6 and lower headers 11 to connect the header connecting pipes 9 of each row to form a rectangular heat transfer body. The outer side of the heat transfer body is a closed casing 20;

[0048] The rectangular heat transfer body is separated by the middle tube plate 3 to form an upper half heat transfer body and a lower half heat transfer body, the upper half...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com