Remote temperature sensing and monitoring system and method for 0.4kV low voltage switch

A low-voltage switch and monitoring system technology, applied in the general control system, control/regulation system, program control, etc., can solve the problem of inability to respond to whether there is an abnormality in the low-voltage switch, whether there is a defect and hidden trouble, missed hidden trouble, and lack of monitoring means and other issues to achieve the effect of improving inspection efficiency and pertinence, improving automation level, and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

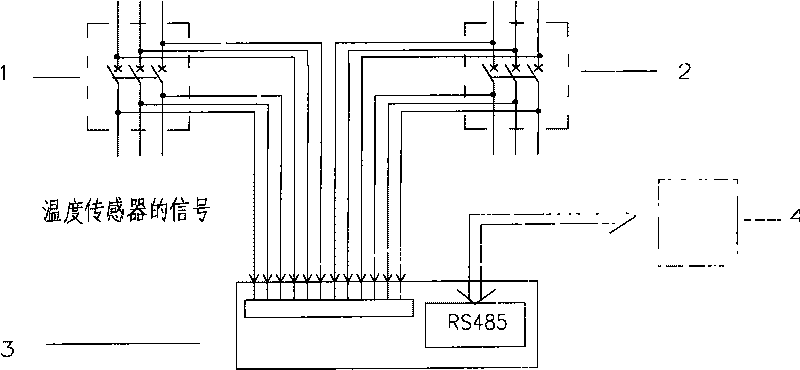

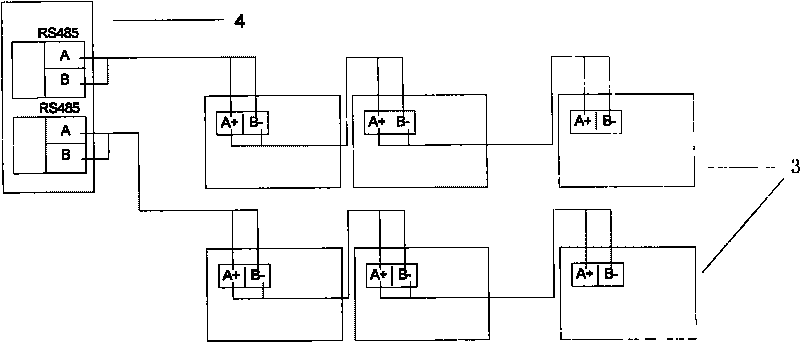

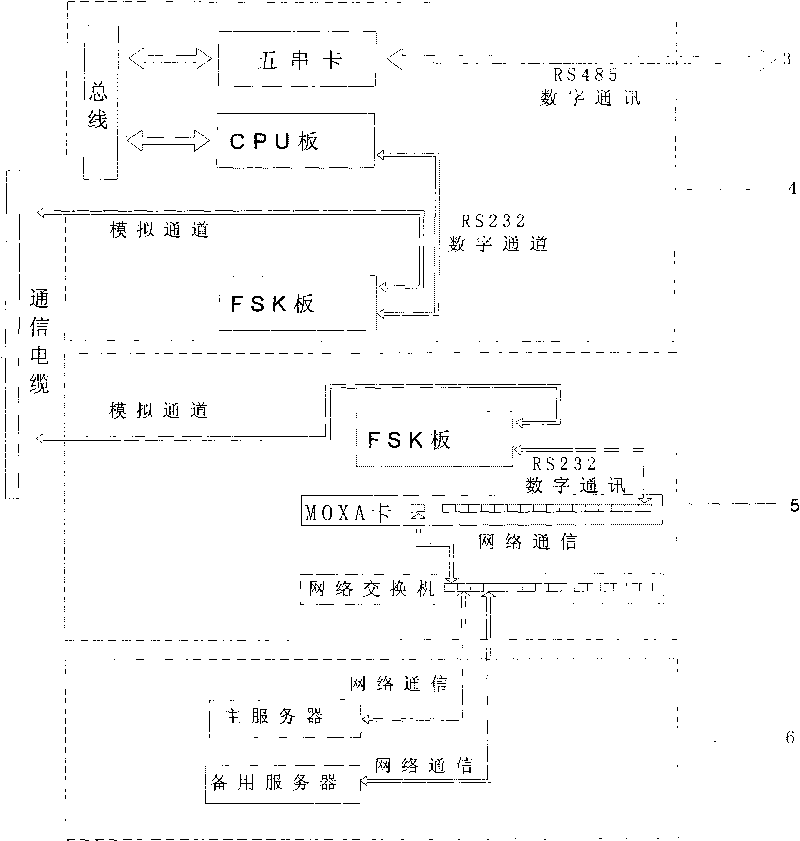

[0023] refer to figure 1 , 2 3. The temperature telemetry and monitoring system of the 0.4KV low-voltage switch of the present invention mainly includes a temperature sensor, a temperature inspection instrument with a communication function, an on-site RTU, a general station RTU, and a computer with monitoring software installed.

[0024] The temperature telemetry and monitoring method of the 0.4KV low-voltage switch of the present invention comprises the following steps:

[0025] (1) Use a temperature sensor to detect the temperature of the live part of each phase contact of the 0.4KV low-voltage switch. In this example, a patch-type temperature sensor is used to paste and fix the temperature sensor on all 0.4kV low-voltage switches in the substation. Such as figure 1 As shown, each 0.4kv switch corresponds to 6 temperature measurement points, and there are 12 temperature measurement points for every two low-voltage switches, that is, 12 SMD temperature sensors. Paste and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com