Method and circuit for setting and reading unique identification code of chip on silicon wafer in batch

An identification code and chip technology, applied in the field of chip programming, can solve the problems of increasing cost, trouble, and incompatibility with standard processes, and achieve the effects of extending life, reducing costs, and reducing deformation and wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

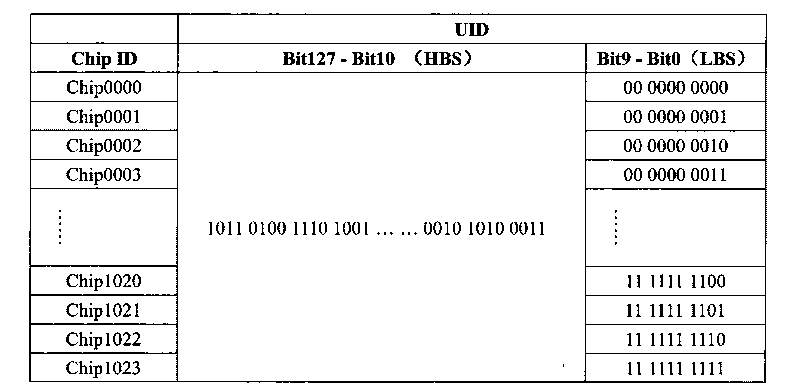

[0036] Observing the arrangement of the UID coded bit string within a certain range, it can be found that: in the UID coded bit string with m bits long and k continuous, the highest bit is defined as the k-1 bit and the lowest bit is the 0th bit. n, first obtain N by finding the logarithm of m with base 2 as N, N=Log(2)m, when N is an integer, n=N, when N is a decimal, n is rounded up to N, n= floor(N), at this time, taking the nth bit as the boundary, in the m unique identification code coded bit strings, the nth bit to the m-1th bit are the same, and the 0th bit to the n-1th bit It changes in increasing or decreasing order. In the coded bit string that defines the unique identification code, the 0th bit to the n-1th bit is the Low End Bit String (LBS), and the nth bit to the m-1th bit is the high-end bit string ( High End Bit String, referred to as HBS).

[0037] Such as image 3 As shown, a string of 128-bit unique identification codes, the lowest bit is the 0th bit, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com