Manufacturing method of medical high white material molded glass bottle

A technology of glass bottles and white materials, which is applied in the field of molding glass bottles with high white materials for medicinal purposes and the field of manufacturing methods, can solve the problems of high fuel consumption, high cost, and high melting point, and achieve fuel saving, lower melting temperature, and higher whiteness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

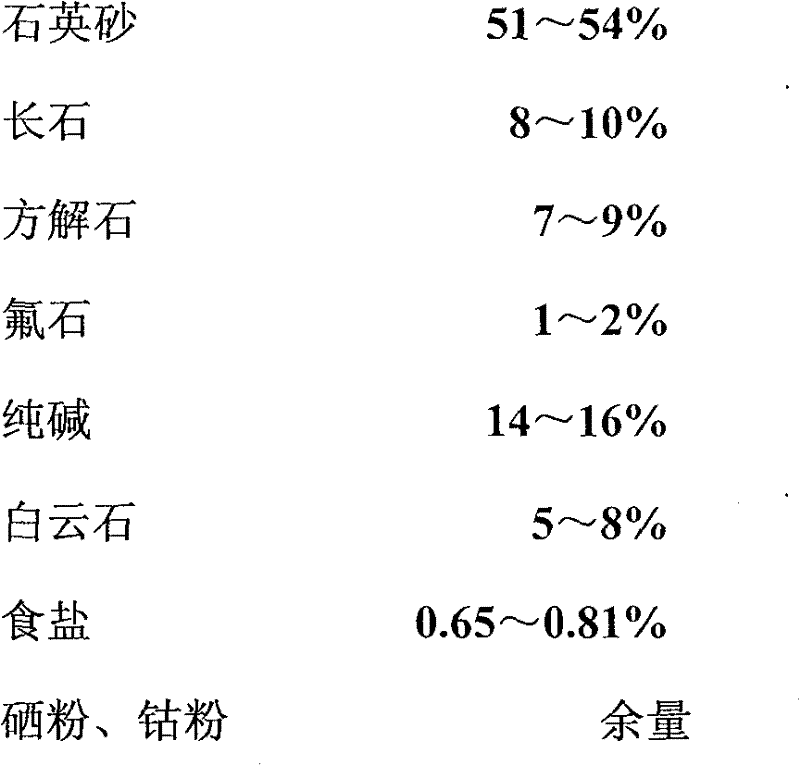

[0029] 1) Raw material formula: 40 parts by weight of cullet, 60 parts by weight of batching materials, wherein the batching materials are formulated according to the following table.

[0030] Table 1: Batch material formula table. Unit: parts by weight

[0031] Example 1 Example 2 Example 3 Quartz sand 51 52 54 Feldspar 10 9 8 Calcite 12 10 7

[0032] Fluorspar 2 1.5 1 soda ash 14 15 16 dolomite 8 7 5 salt 0.65 0.75 0.81 Selenium powder 1 1.25 5 cobalt powder 1 3 3.19

[0033] 2) preparation method: batching is selected from the formula of any one of embodiment 1-3

[0034] The raw materials are mixed and added to the kiln, melted at a high temperature of 1400°C, and then shaped in the glass forming equipment, finally annealed, inspected, and packaged for storage after passing the test.

[0035] The invention aims at improving the whiteness, transparency, strength and loweri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com