Megawatt grade brushless slip ring double-fed wind generator/motor and control method thereof

A technology of wind power generator and control method, which is applied in the direction of motor generator control, electronic commutation motor control, control generator, etc., and can solve the problems of generator scrapping, permanent magnet demagnetization, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

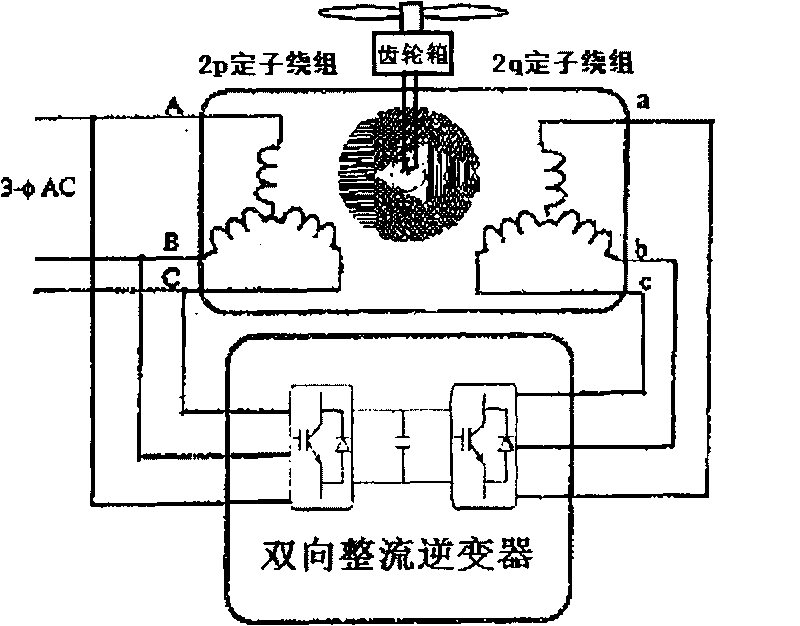

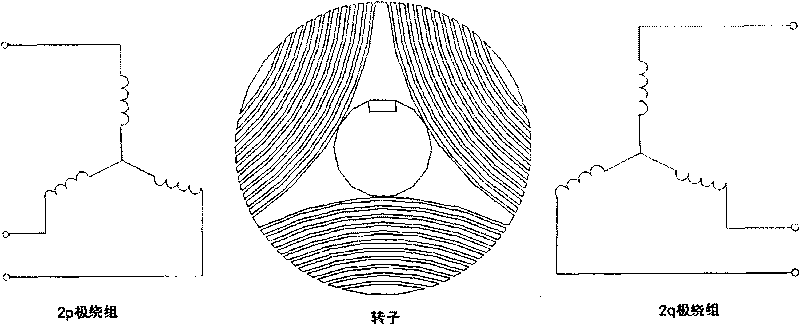

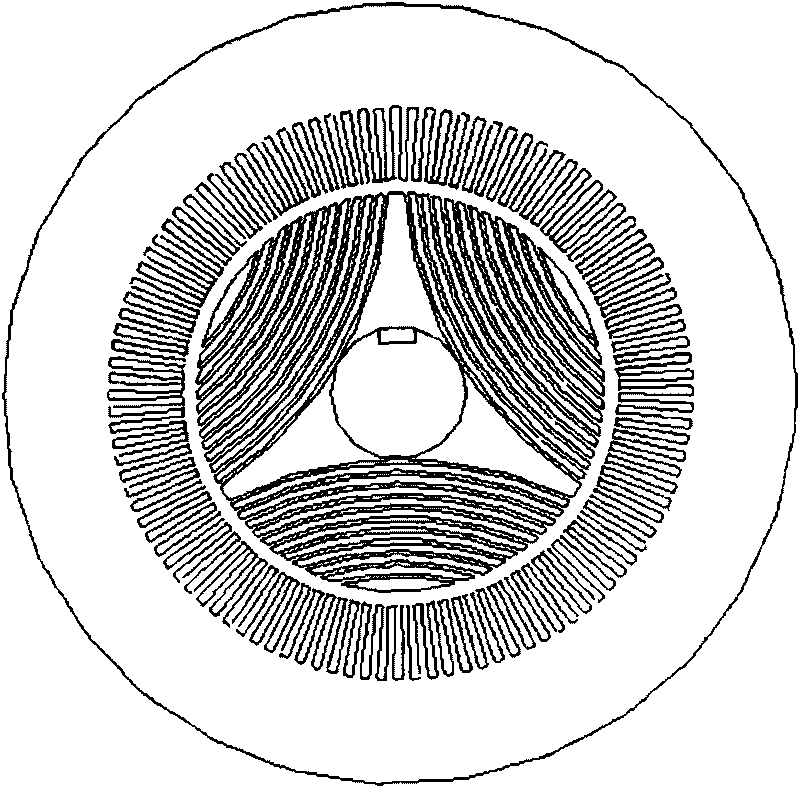

[0058] The megawatt-level brushless doubly-fed motor provided by the present invention is as figure 1 and figure 2 As shown, it includes stator, rotor and bidirectional rectifier inverter, in which there are two sets of independent sinusoidal distributed windings on the stator, the number of poles is 2p and 2q respectively, and the number of poles of the rotor is 2p r , where p, q and p r are all positive integers. The 2p stator winding is used as the main power winding and is directly connected to the grid. The 2q stator winding is used as a power control winding, and is connected to the power grid or external circuit through the AC / DC / AC bidirectional rectification inverter. The above-mentioned 2p stator winding and 2q stator winding are multiphase symmetrical windings. The rotor is a reluctance modulated rotor, which is directly or indirectly connected to the fan rotor through a gearbox. The wind wheel drives the rotor to rotate through the transmission of the gear in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com