Optical pickup device and collimate lens

一种光拾取装置、准直透镜的技术,应用在光束引导装置、光束源、光学记录头等方向,能够解决位置调节难、交调失真、机构复杂等问题,达到吊架结构简化、占有容积降低、零件个数减少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

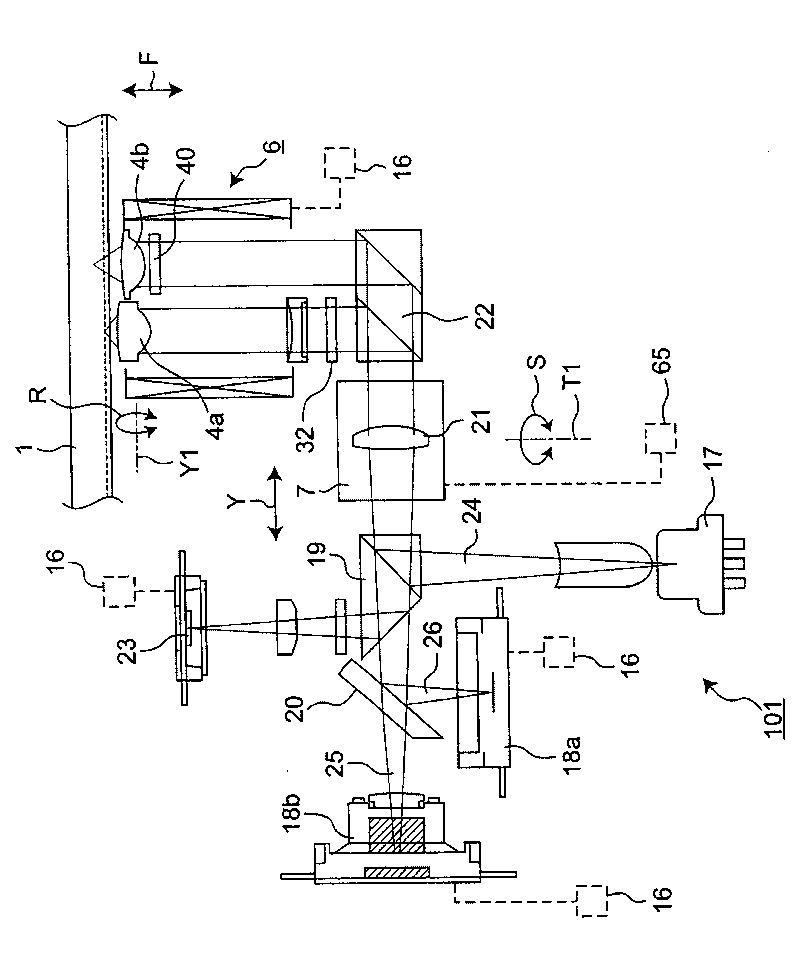

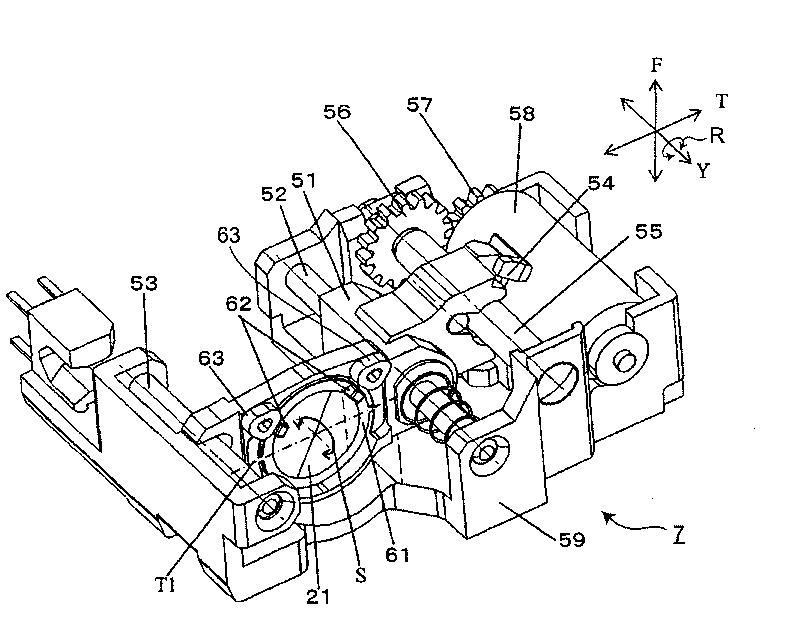

[0096] refer to figure 1 The configuration of the optical pickup device 101 according to Embodiment 1 of the present invention will be described.

[0097] The optical pickup device 101 of this embodiment is an optical pickup device that records or reproduces information by converging a light beam emitted from a light source toward an optical disc as an optical recording medium by a converging optical system on the optical recording medium. Such an optical pickup device 101 is roughly divided into the above-mentioned light source, a first coma correction actuator, and a second coma correction actuator. Here, the first and second coma aberration correction transmission mechanisms constitute a part of the above-mentioned condensing optical system. In addition, the first coma aberration correction actuator has a first tilt drive unit that tilts the objective lens that emits light onto the optical disc in a first inclination direction, and the second coma aberration correction act...

Embodiment approach 2

[0208] Next, an optical pickup device according to Embodiment 2 of the present invention will be described with reference to the drawings.

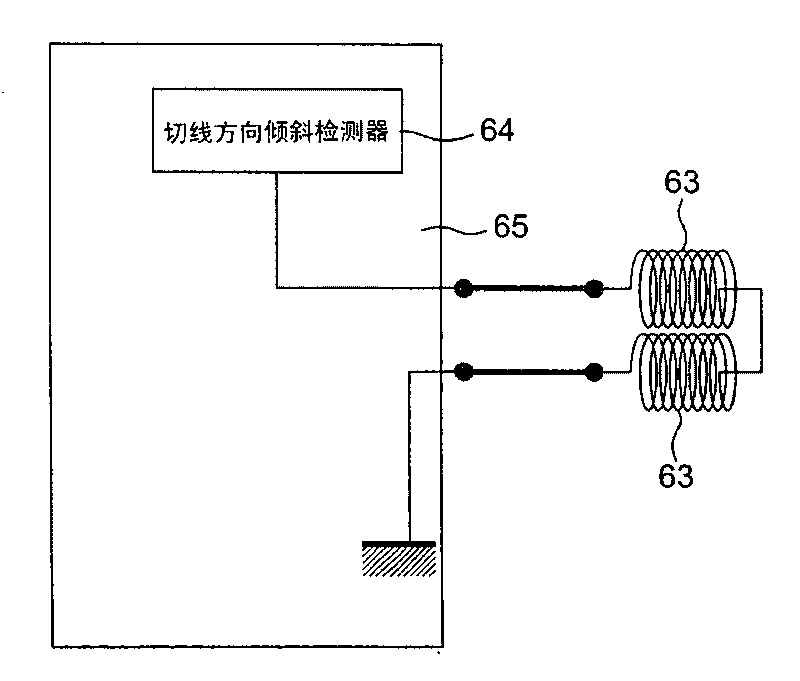

[0209] Figure 11 It is a configuration diagram showing the configuration of the collimator lens actuator 7-2 of the optical pickup device according to the second embodiment.

[0210] exist Figure 11 in, with figure 2 The difference of the collimator lens 7 shown is that the movable magnet 62 and the fixed tangential direction tilt coil 63 of the tangential direction tilt driving part of the collimator lens transmission mechanism 7, in the collimator lens transmission mechanism 7- 2 is replaced by a fixed magnet 66 and a movable tangentially inclined coil 67. In the collimator lens actuator 7 - 2 , the other components are not changed, and the same reference numerals are assigned to the components having the same functions as those of the collimator lens actuator 7 .

[0211] Therefore, hereby refer to Figure 11 With regard to the...

Embodiment approach 3

[0215] Next, an optical pickup device according to Embodiment 3 of the present invention will be described with reference to the drawings.

[0216] Figure 12 It is a configuration diagram showing the configuration of the collimator lens actuator 7-3 of the optical pickup device according to the third embodiment.

[0217] exist Figure 12 in, with figure 2 The difference of the collimator lens 7 shown is that the movable magnet 62 and the fixed tangential direction tilt coil 63 of the tangential direction tilt driving part of the collimator lens transmission mechanism 7, in the collimator lens transmission mechanism 7- 3, it is replaced by a piezoelectric element 68. In the collimator lens actuator 7 - 3 , the other components are not changed, and the same reference numerals are assigned to the components having the same functions as those of the collimator lens actuator 7 .

[0218] Therefore, hereby refer to Figure 12 Regarding the collimating lens transmission mechan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com