Arbor cropper capable of automatically adjusting cutter positions

A technology of automatic adjustment and pruning machine, which is applied in the direction of agricultural machinery and tools, cutting tools, cutting equipment, etc. It can solve the problems of high risk factor, reduced economic benefits of forest trees, and slow pruning speed, so as to reduce labor intensity and improve pruning. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

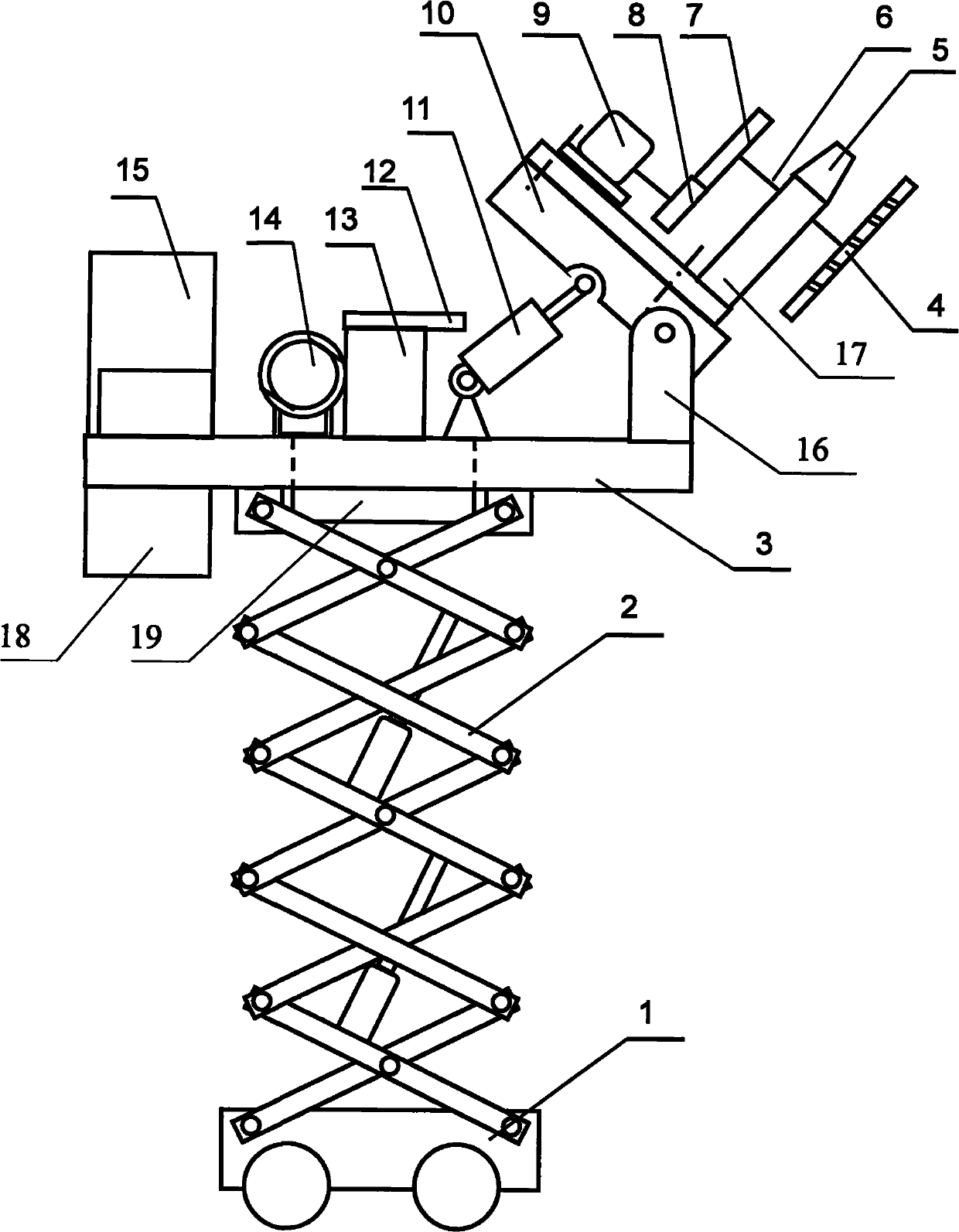

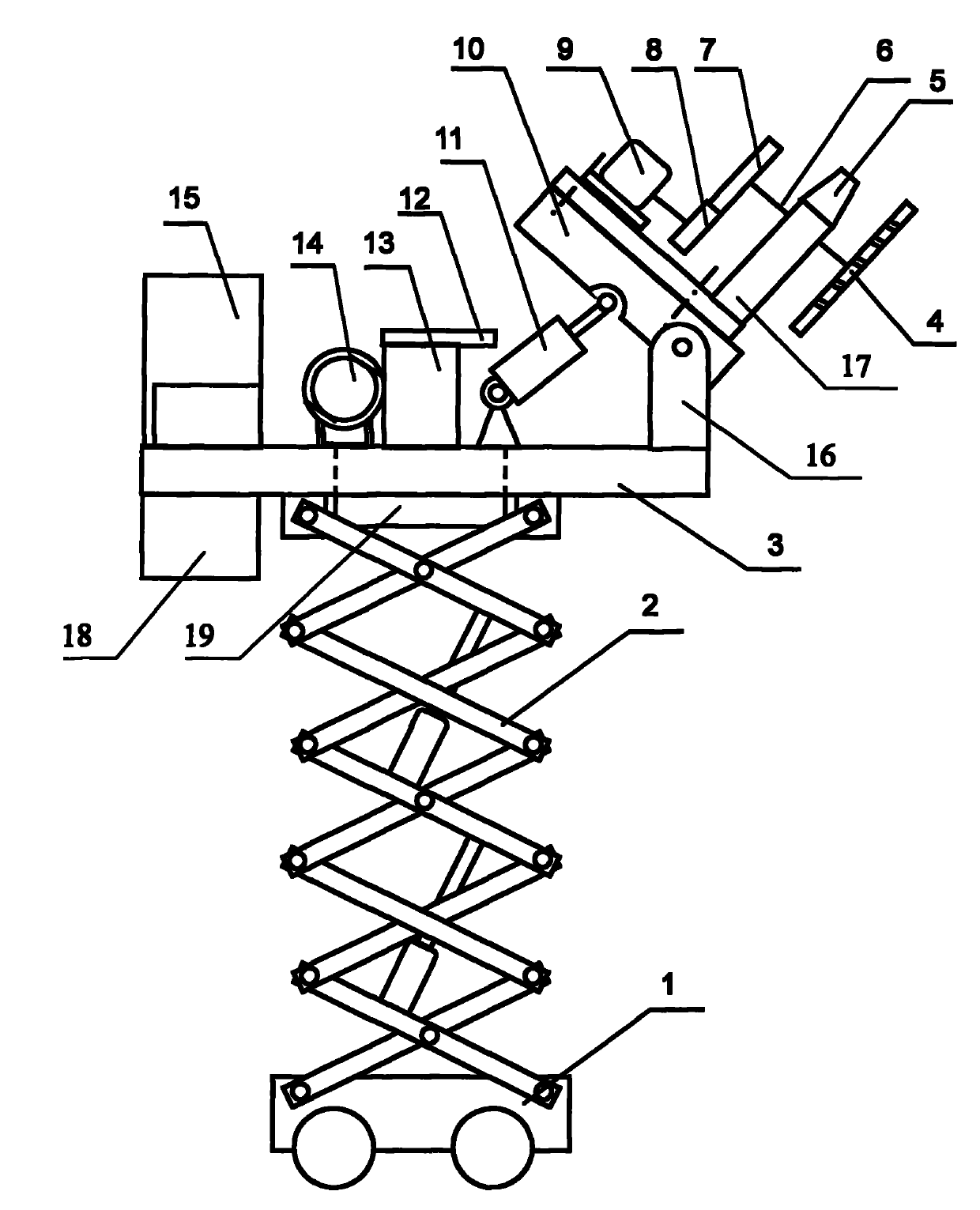

[0011] Example: such as figure 1 As shown, the arbor pruning machine with automatic knife adjustment includes a driving part 1 and a lifting frame 2. The driving part 1 is provided with a vertical and horizontal two-way driving device, and the lifting frame 2 is a scissor type lifting frame; the upper end of the lifting frame 2 is provided with a main bracket. 3. The main bracket 3 is equipped with a generator 15, a position adjustment device and a shearing device. The position adjustment device includes a workbench 10, one end of the workbench 10 is hinged to the upper end of the bracket 16 provided on the main bracket 3, and the bottom of the workbench 10 is connected to the piston rod of the swing hydraulic cylinder 11 arranged on the main bracket 3 , the swing hydraulic cylinder 11 is connected with the motor and the hydraulic pump 14 and a hydraulic control part 13 is set, the top of the hydraulic control part 13 is provided with a workbench support 12, the motor and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com