Reproducing method of forging mold by using composite build-up welding and spray welding method

A composite welding and remanufacturing technology, used in manufacturing tools, welding equipment, melt spraying, etc., can solve the problems of large machining costs and heat treatment costs, difficulty in mold performance, low economic benefits, etc., and achieve enhanced surface resistance. Abrasion and thermal fatigue resistance, optimized strength and impact toughness, matrix material savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

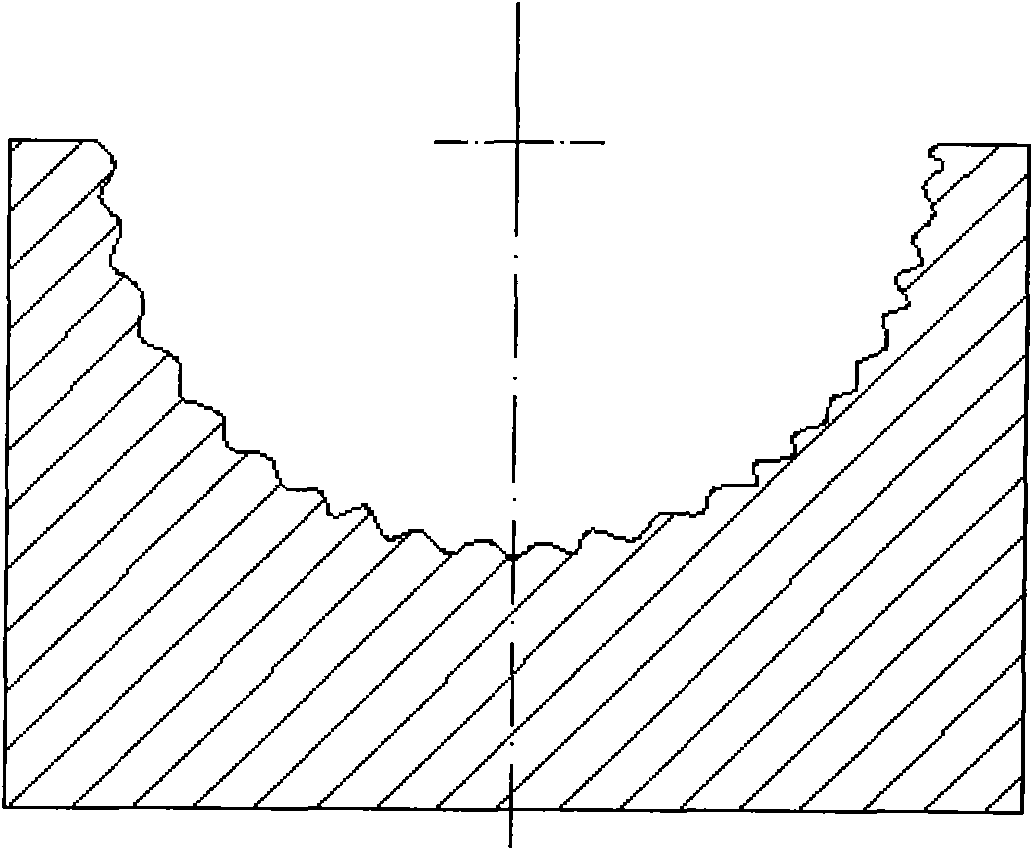

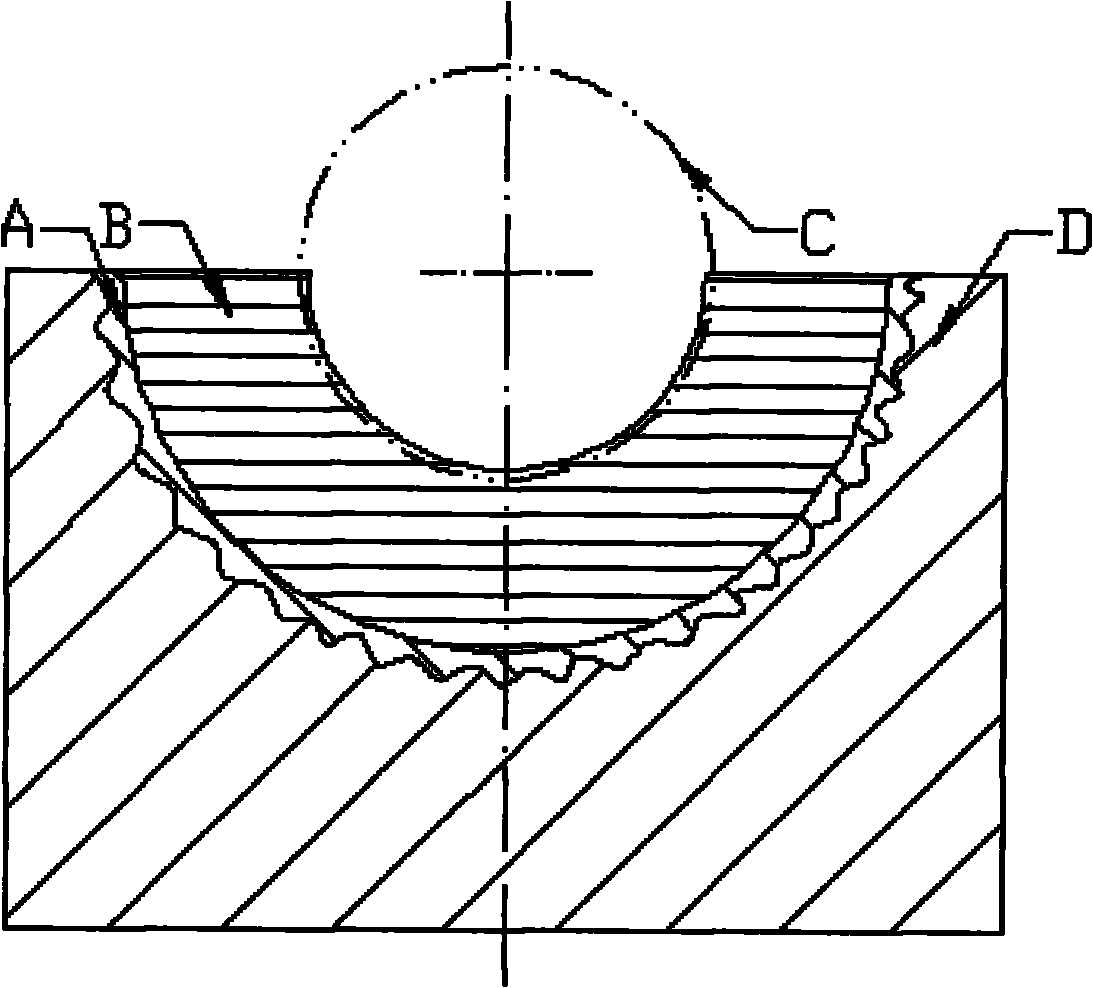

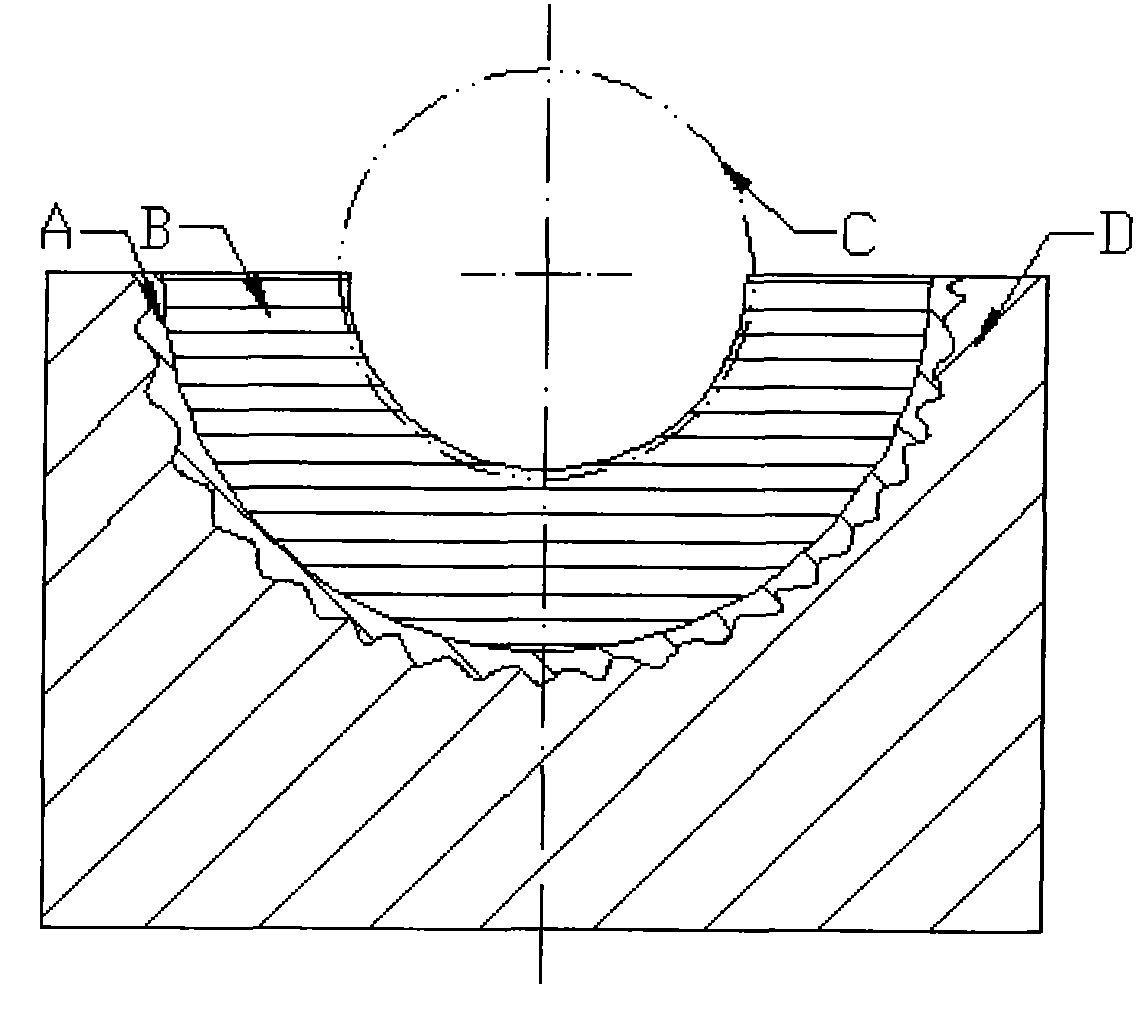

[0033] The forging die to be repaired in this specific embodiment is the lower die of an ordinary forging die, and the cross-sectional structure to be welded is as follows: figure 1 As shown, its repair method includes the following steps executed in sequence:

[0034] a. The cavity of the forging mold to be repaired is planed down to remove the failure part to form a wavy surface, such as figure 1 shown.

[0035] b. Perform one-step spray welding of self-fluxing alloy powder on the wavy surface of the mold to form a uniformly distributed spray welding layer, which serves as a transition layer.

[0036] c. Adopt automatic gas shielded surfacing welding process, and carry out surface strengthening layer surfacing welding on the spray welding surface of the transition layer of the mold.

[0037] d. The mold adopts tempering and slow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com