Security film

A safety film and safety film technology, applied in the direction of lamination, layered products, synthetic resin layered products, etc., can solve the problem of unsatisfactory effect of glass safety film withstanding strong impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

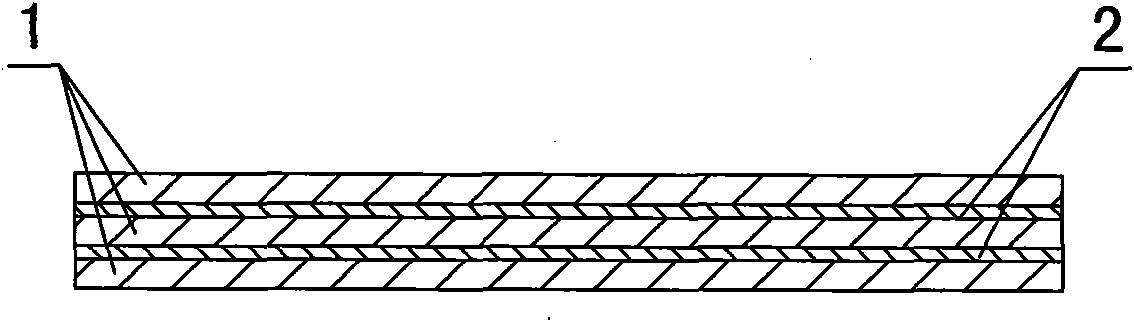

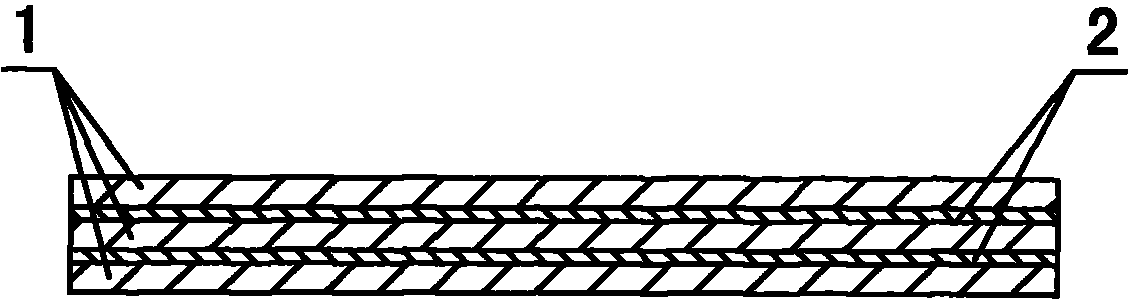

[0014] Such as figure 1 Shown, the material that the glass safety film of number of the present invention adopts is polyethylene terephthalate (PET), and glass safety film can make common glass reach the function of preventing accident injury, anti-theft, anti-riot (bomb).

[0015] The glass safety film of the present invention is a polyethylene terephthalate film sheet with a thickness of 0.125-0.8mm produced by calendering, bonding and stacking. The base film of the safety film is a 0.1mm polyvinyl alkyl ester calendered film 1. After coating the polyacrylic pressure-sensitive adhesive 2 on it, another piece of the basic film 1 is superimposed and pressed according to the requirements. The glass safety film is formed by stacking multiple layers.

[0016] The glass safety film of the present invention is produced by a conventional production process, that is, it is formed by calendering. After the base film 1 is generated, the adhesive 2 is coated on it, and then the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com