Auto-waterproof bridging particle

A technology of waterproof plugging and plasticizer, which is applied in the field of engineering materials, can solve the problems of difficult construction operation, fast setting time, and insufficient strength, and achieve the effects of shortening setting time, improving early strength, and improving impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to disclose more clearly, the present invention is described from several aspects below.

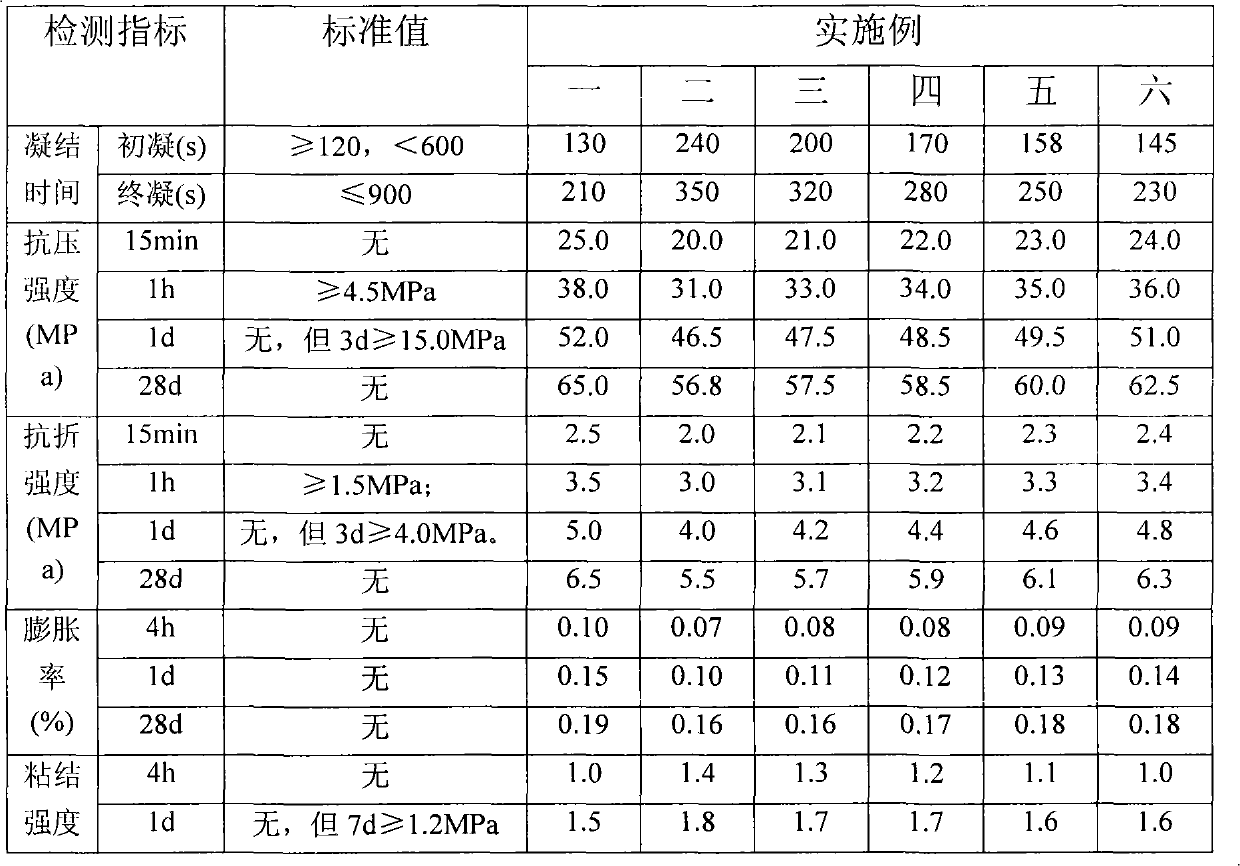

[0020] For waterproof plugging materials, from a mechanism point of view, the three most important indicators are: setting time, strength, and impermeability (expansion rate). Only by meeting the requirements of these three indicators can we get good results in engineering.

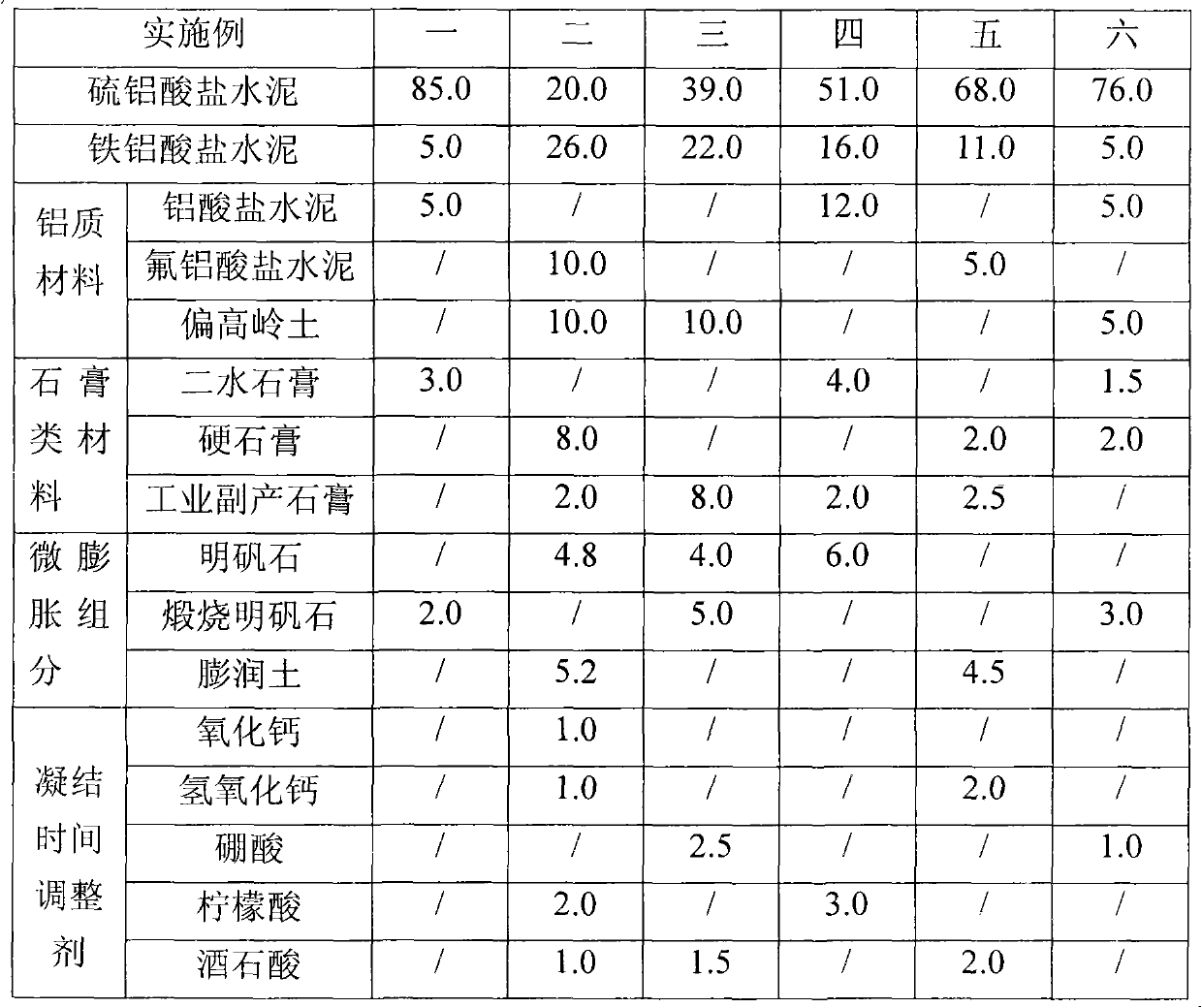

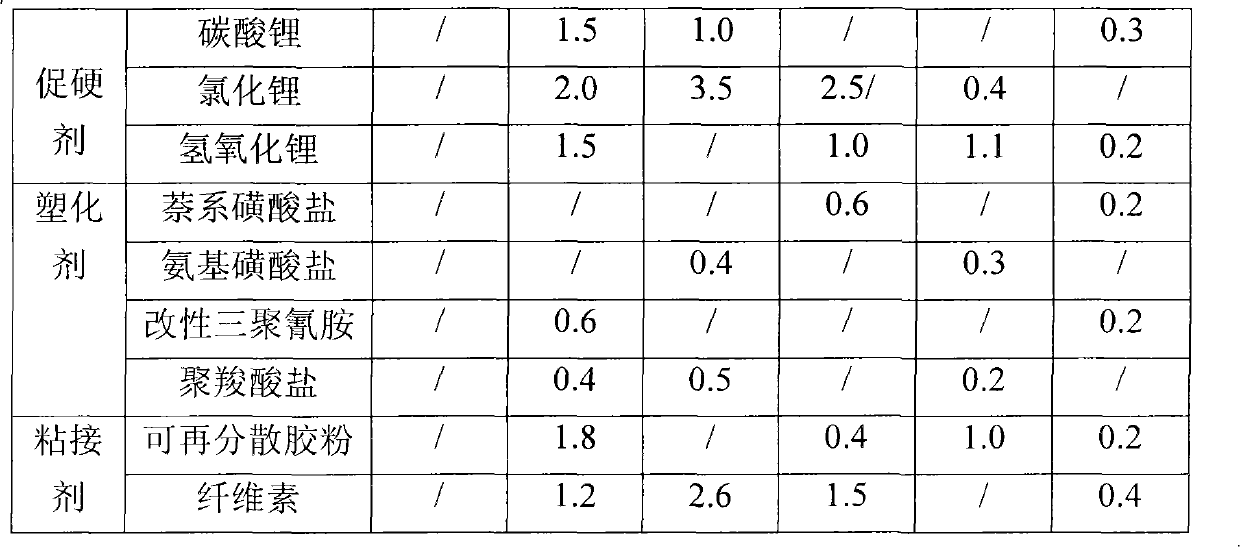

[0021] The self-waterproof high-performance quick-acting plugging agent provided by the present invention is based on sulphoaluminate cement (including iron-aluminate cement) and aluminum materials that meet the current standard requirements, adding appropriate amount of gypsum, micro-expansion components, coagulation The time adjusting agent, hardening agent, plasticizer, adhesive and other materials for improving the performance of waterproof and leak-proofing are prepared together, so that the above-mentioned performance of the material is obviously better than that of the existing waterproof and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com