Multi-beam structure glass fiber reinforced plastic vierendeel vane of megawatt wind generator and producing method thereof

A technology for wind turbines and beam structures, which is applied in the field of wind power to achieve the effects of reducing mass, improving flexibility, and increasing bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

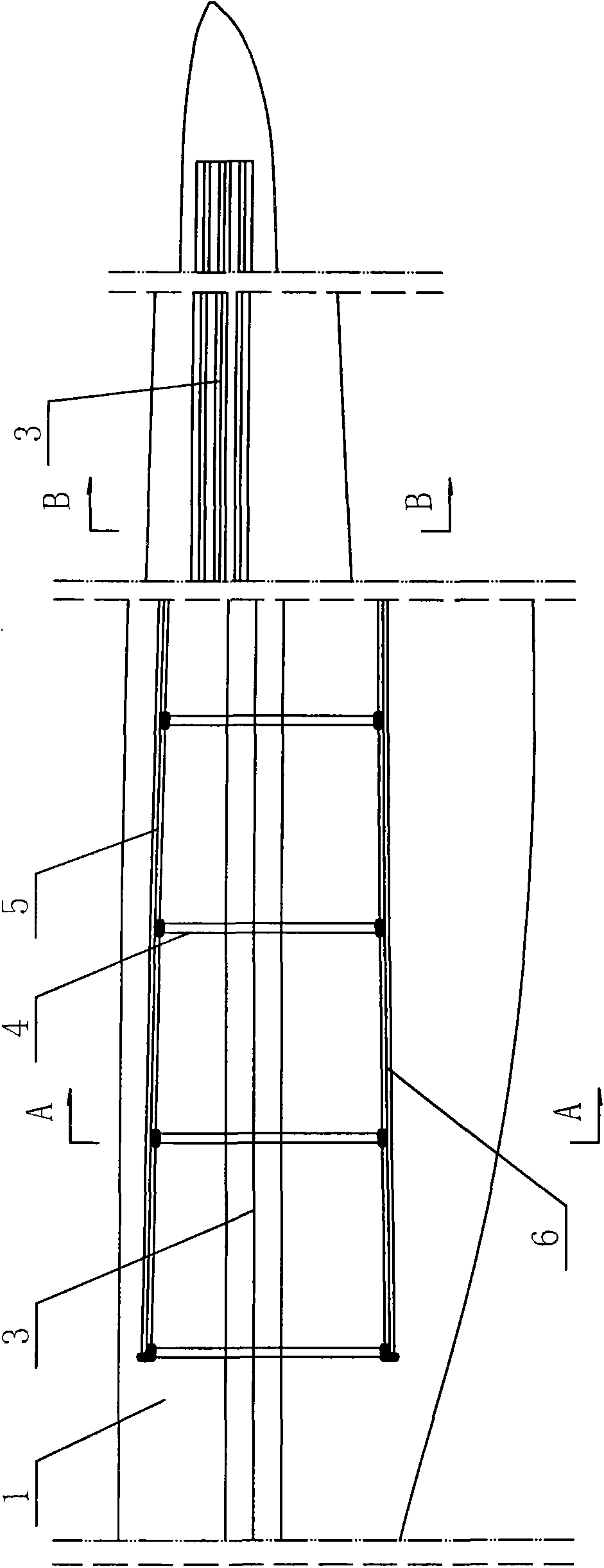

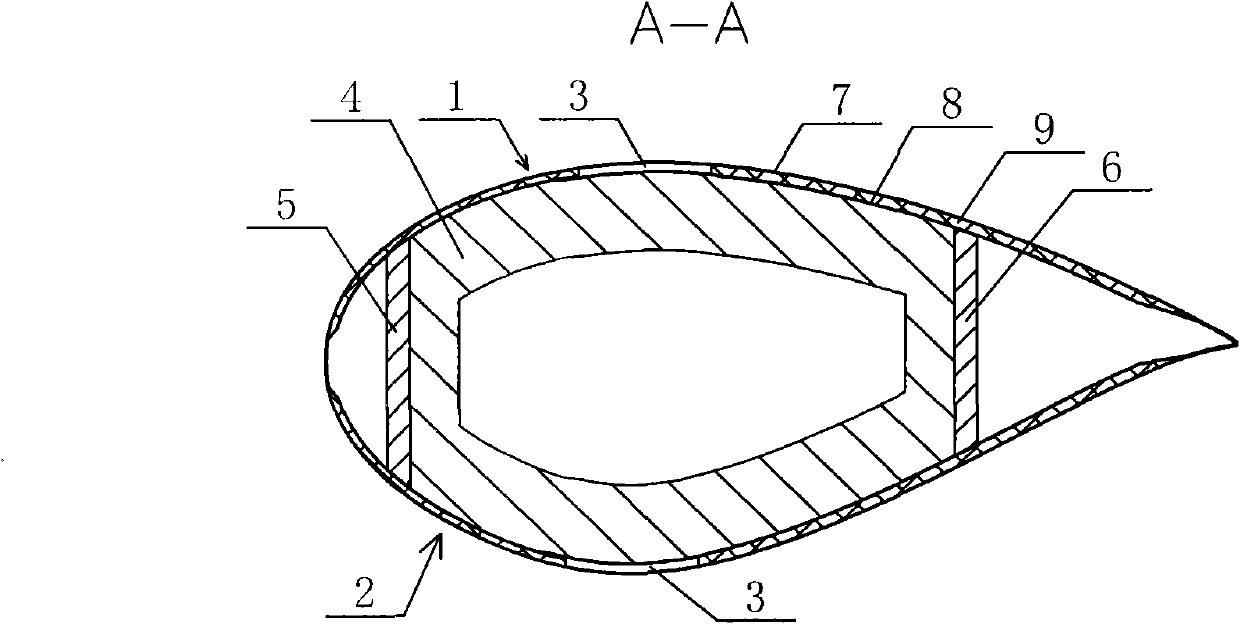

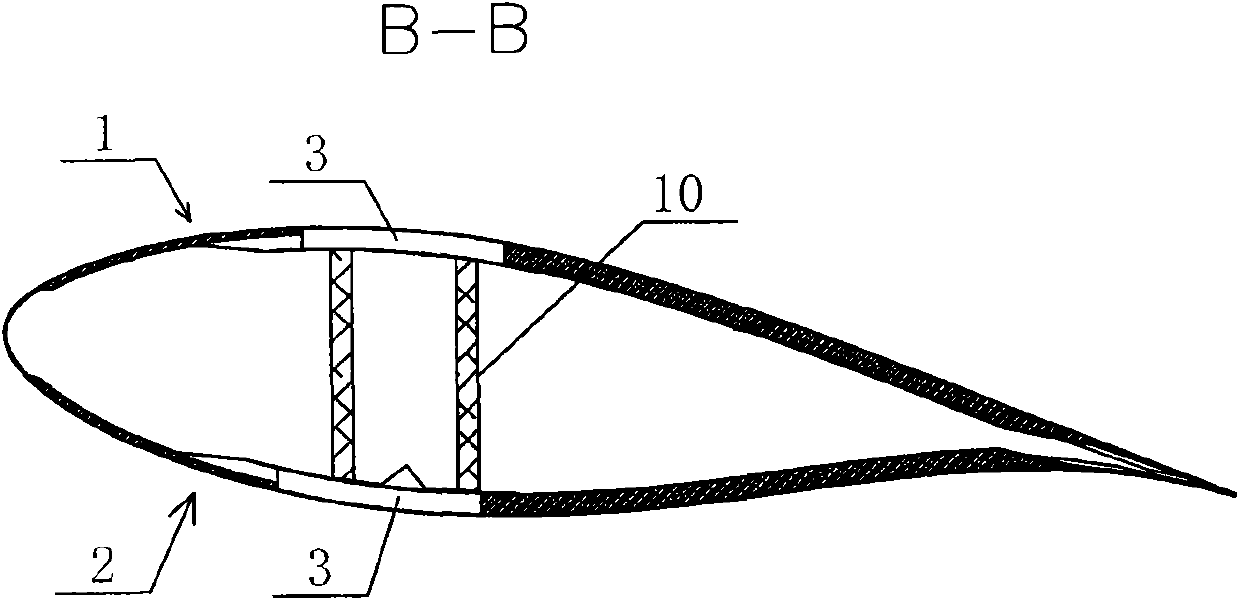

[0036] The multi-beam structure FRP hollow blade of the megawatt class wind power generator of the present embodiment, such as figure 1 , figure 2 As shown, it includes two leaf shells 1, 2 ( figure 2 As shown, 1 is the blade shell on the pressure surface, 2 is the blade shell on the suction surface), and the main beam 3 fixed on the inner side of the blade shell. It is ring-shaped, and its upper and lower sides are glued and fixed to the inner skin 8 of the two leaf shells and the main beam 3. figure 2 Among them, 7 is the outer skin of the leaf shell, 8 is the inner skin of the leaf shell, and 9 is PVC foam. The main frame of the blade is formed by the rib and the main beam, and the original overall force-bearing blade is changed to a small unit area force, which enhances the torsion of the blade and improves the strength of the blade.

[0037] Such as figure 1 , figure 2 As shown, in this embodiment, two auxiliary shear webs 5, 6 are also arranged inside the leaf...

Embodiment 2

[0040] Such as Figure 4Shown is the cross-sectional view of the blade of this embodiment. In the figure, 1 is the blade shell on the pressure side, 2 is the blade shell on the suction side, 3 is the main beam, 4 is the rib, and the auxiliary shear webs 5 and 6 are respectively fixed on the ribs. On both sides of 4, 7 is an outer skin, 8 is an inner skin, and 9 is a PVC foam. The improvement of this example with respect to Embodiment 1 is that auxiliary beams 11 are respectively arranged on both sides of the main beam 3 of the blade shell, the inner side of the auxiliary beam 11 is bonded and fixed to the rib 4, and the outer side is bonded to the blade shell 1, 2 inner skins 8 are fixed as one. The single-beam is improved to multi-beam, the force on the blade is more reasonable, and the shimmy stiffness of the blade and the stability of the blade structure can be improved. The grid structure formed by the multi-beam and rib improves various mechanical properties and reduces ...

Embodiment 3

[0042] The blade of the present invention also has a structural transformation, that is, two main beams are arranged in each blade shell (the structure of the hollow rib is the same as that of Embodiment 1 and 2), which also forms a mesh structure, changing the traditional blade from a single beam Concentrated force is multi-beam distributed force, which improves the overall strength. In order to further improve the mechanical performance of the blade, in this example, several auxiliary beams are arranged inside each blade shell, the inner side of the auxiliary beam is bonded and fixed with the rib, and the outer side is fixed with the inner skin of the blade shell as a whole.

[0043] Blade production method embodiment 1

[0044] This embodiment is a method for producing a multi-beam structure FRP hollow blade of a megawatt-level wind power generator, such as Figure 5 In order to utilize the female mold to produce the schematic diagram of the suction surface of the blade, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com