Ytterbium-doped ultrashort pulse fiber laser for dispersion compensation in cavity

A fiber laser and ultrashort pulse technology, which is applied in lasers, laser components, phonon exciters, etc., can solve the problem that ytterbium-doped ultrashort pulse fiber laser cannot realize self-starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

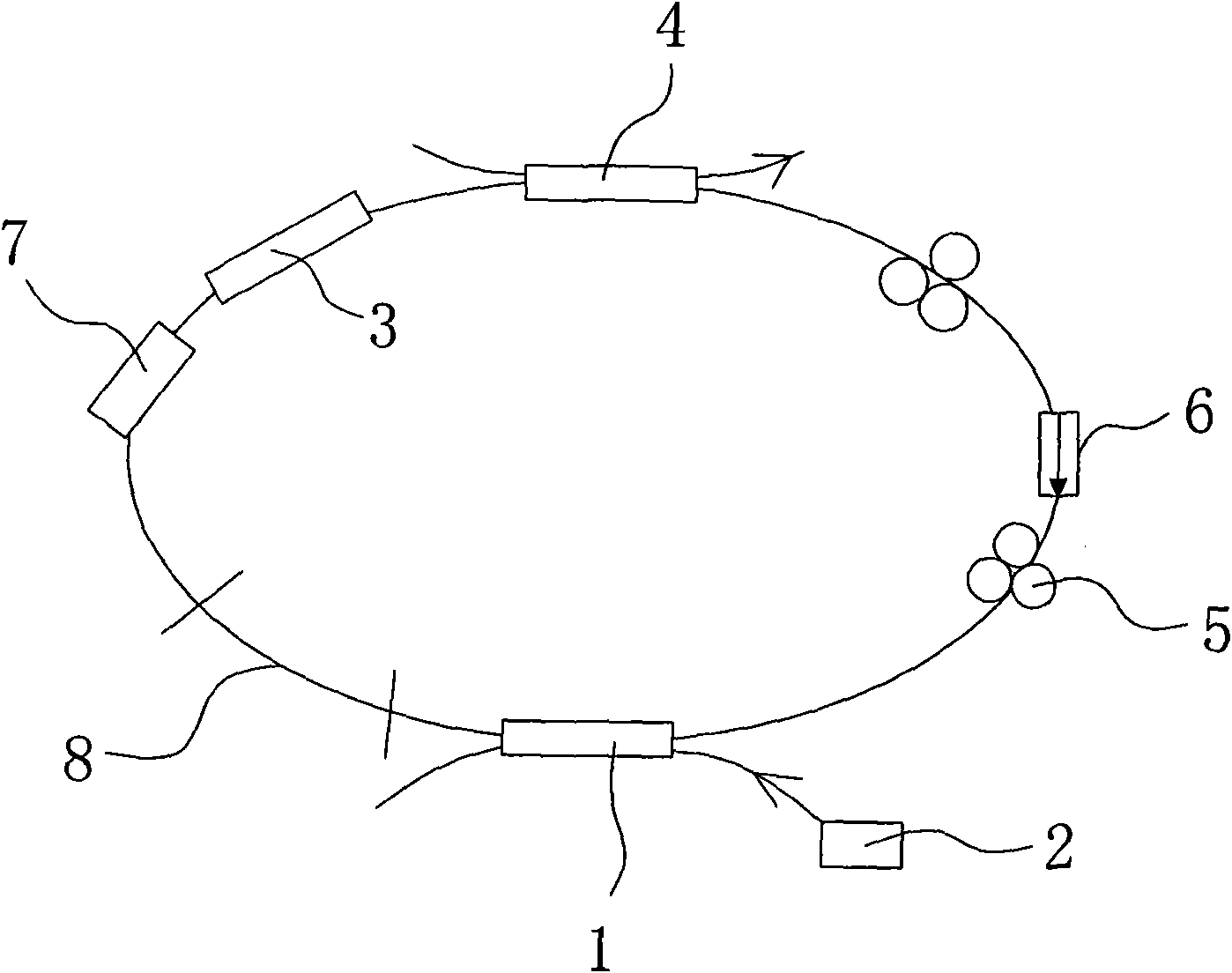

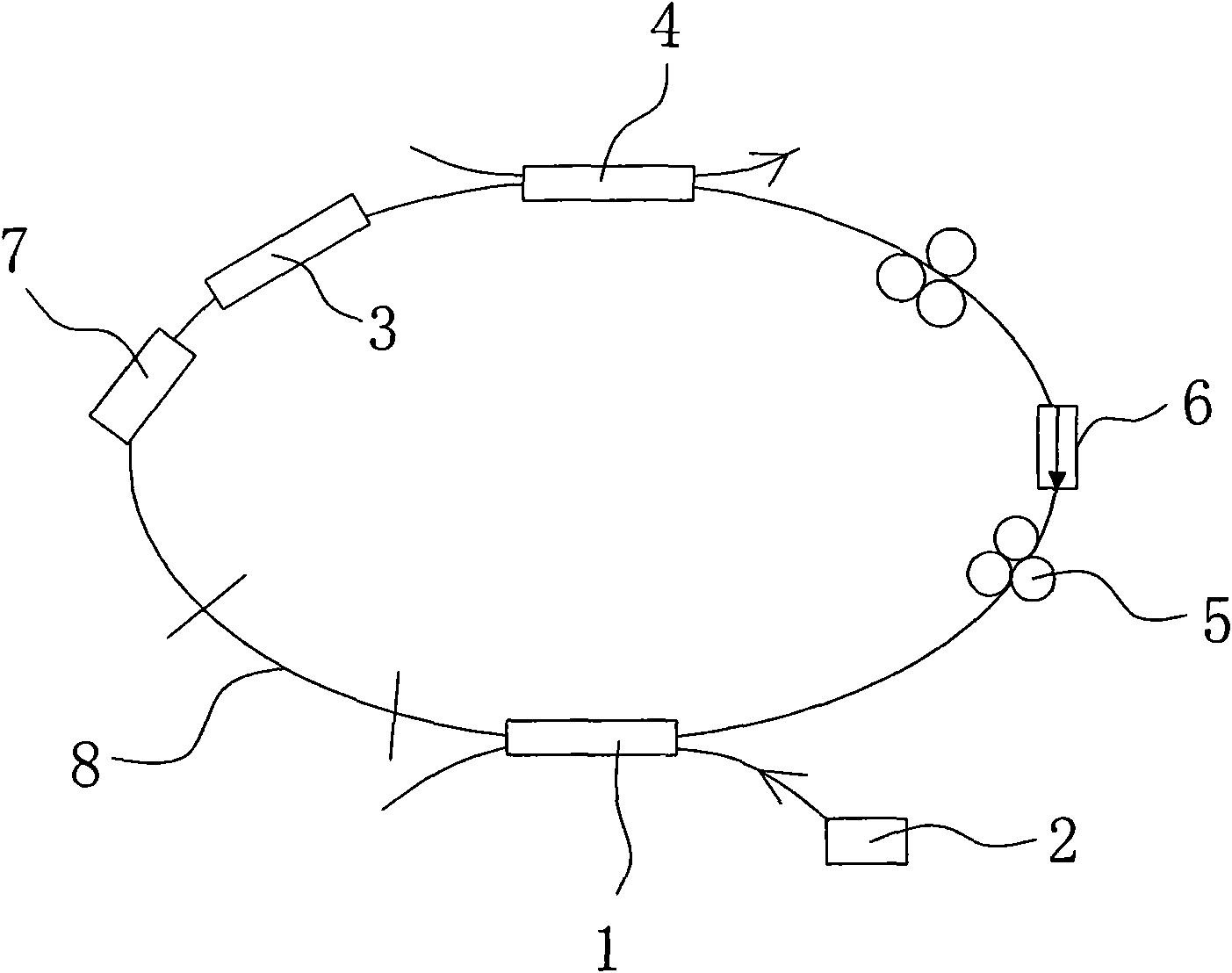

[0014] see figure 1 , a ytterbium-doped ultrashort pulse fiber laser with intracavity dispersion compensation, comprising a semiconductor pump source 2 connected to the input end of a wavelength division multiplexer 1, a photonic crystal fiber 3 sequentially connected to the output end of the wavelength division multiplexer 1 , optical fiber coupler 4, polarization controller 5 and optical isolator 6, both ends of optical isolator 6 are provided with polarization controller 5, described wavelength division multiplexer 1, photonic crystal fiber 3, optical fiber coupler 4. The polarization controller 5 and the optical isolator 6 are welded by optical fibers to form an annular cavity. A transmissive semiconductor saturable absorber 7 is arranged between the wavelength division multiplexer 1 and the photonic crystal fiber 3. The transmissive semiconductor saturable absorber 7 is used for mode locking of the ytterbium-doped ultrashort pulse fiber laser; a section of the fiber betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com