Pot body seed tray and pot body seeder

A sowing tray and seeder technology, which is applied in the direction of single-grain seeder, seeder parts, etc., can solve the problems of high cost, missed sowing, complex control structure, etc., and achieve good applicability, avoid missed sowing, and high seeding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

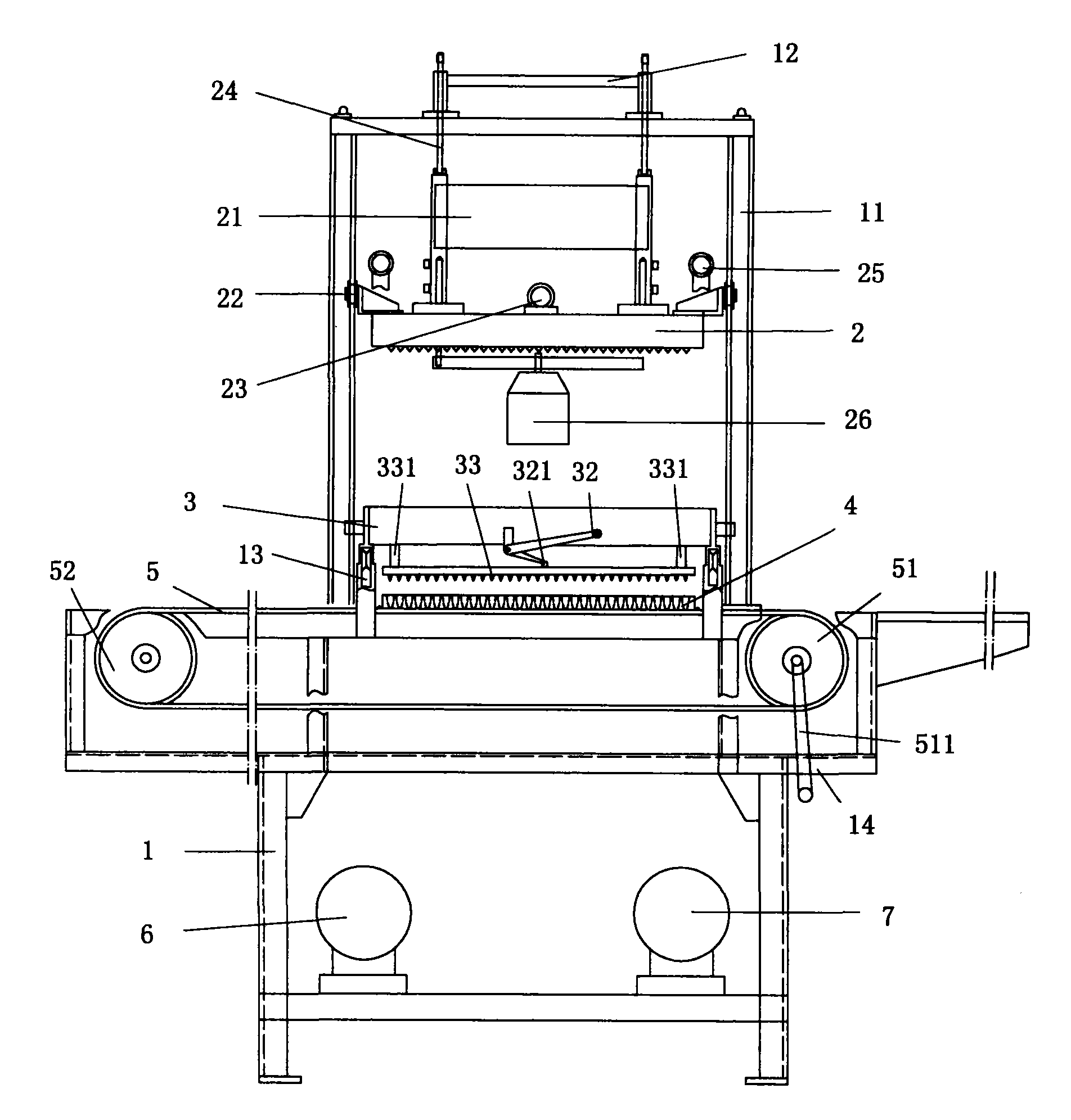

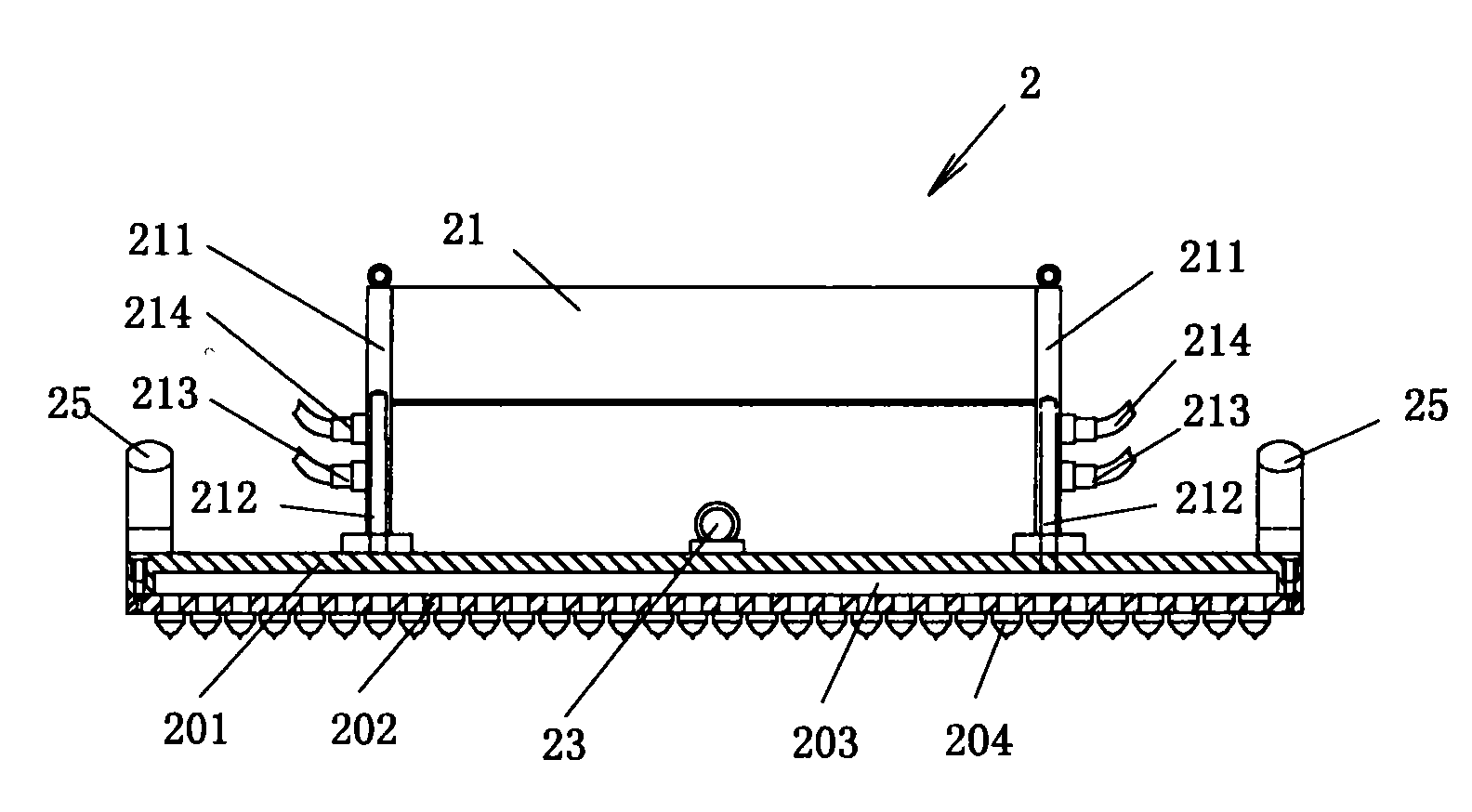

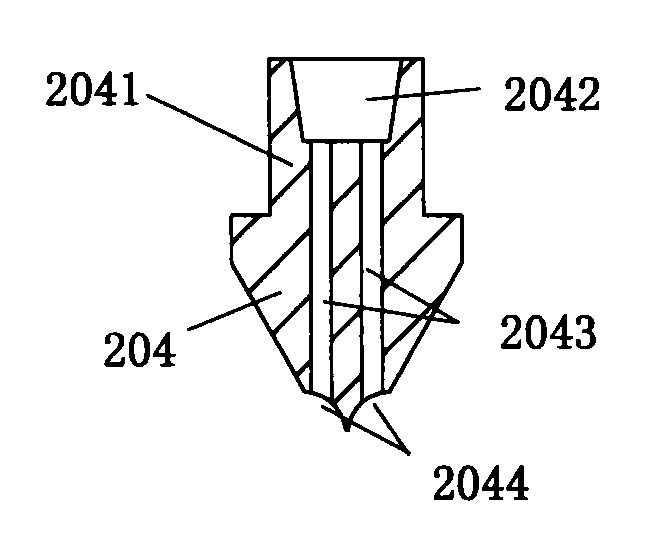

[0024] The front structure of an embodiment of the pot planter of the present invention, such as figure 1 As shown, the frame 1 of the pot planter is provided with a pot seeding tray 2, a seed tray 3, a pot seedling tray 4, a transmission belt 5, a negative pressure fan 6 and a positive pressure fan 7.

[0025] The upper part of the frame 1 is provided with a door-shaped bracket 11. The upper beam of the door-shaped bracket 11 is fixedly installed with a synchronous sprocket mechanism 12. The left and right sides of the bracket of the synchronous sprocket mechanism 12 each fix a set of sprocket wheels. Please see Figure 4 , Each set of sprocket includes a rear sprocket 121 at the rear end of the bracket and a front sprocket 122 at the front end of the bracket. The two rear sprockets 121 are coaxially coupled, or the two front sprockets 122 are coaxially coupled, and the two sets of sprockets form a synchronous rotation. Each chain wheel is provided with a chain 24; the front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com