Fermentation method for high-quality Pu'er tea

A fermentation method and Pu-erh tea technology, applied in tea treatment before extraction, climate change adaptation, etc., to achieve good fermentation quality, save space and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

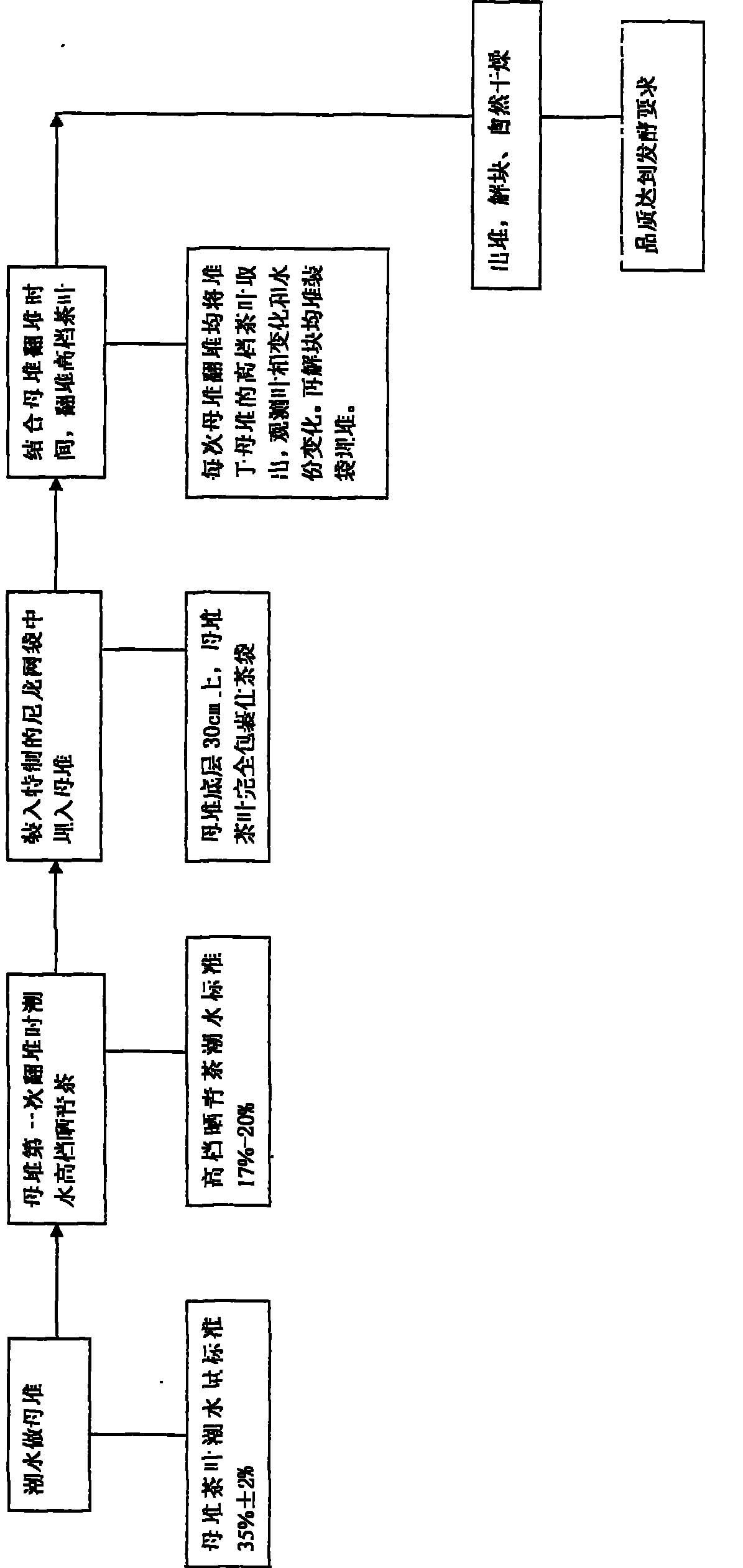

[0014] High-grade Pu'er tea fermentation method of the present invention is as follows:

[0015] 1. Make a mother heap: According to the production needs, a pile of bulk sun-dried green tea of more than 5 tons is used as the mother heap, and the tidal water volume is controlled at 35%;

[0016] 2. When the mother pile is turned over for the first time, the high-grade sun-dried green tea is given tide water, and the tide water volume is controlled at 18%;

[0017] 3. Put the high-grade sun-dried green tea after the tide into a nylon mesh bag, and tie up the mouth of the bag;

[0018] 4. Put the bagged high-grade tea on the middle layer above the bottom 30cm of the mother heap, and completely wrap the tea bags with the tea leaves of the mother heap;

[0019] 5. Every time the mother heap is turned over in the future, each bag of tea is taken out, deblocked and turned over, and then packed into the mother heap, and the moisture content and sensory evaluation are carried out at...

Embodiment 2

[0021] 1. Make a mother heap: According to the production needs, first flood a pile of bulk sun-dried green tea of more than 5 tons as the mother heap, and the tidal water volume is controlled at 37%;

[0022] 2. When the mother pile is turned over for the first time, the high-grade sun-dried green tea is given tide water, and the tide water volume is controlled at 17%;

[0023] 3. Put the high-grade sun-dried green tea after the tide into a nylon mesh bag, and tie up the mouth of the bag;

[0024] 4. Put the bagged high-grade tea on the middle layer above the bottom 30cm of the mother heap, and completely wrap the tea bags with the tea leaves of the mother heap;

[0025] 5. Every time the mother heap is turned over in the future, each bag of tea is taken out, deblocked and turned over, and then packed into the mother heap, and the moisture content and sensory evaluation are carried out at the same time. When it comes out of the heap, it will be unblocked after being out of...

Embodiment 3

[0027] 1. Make a mother heap: According to the production needs, a pile of bulk sun-dried green tea of more than 5 tons is used as the mother heap, and the tidal water volume is controlled at 33%;

[0028] 2. When the mother pile is turned over for the first time, the high-grade sun-dried green tea shall be given tide water, and the tide water shall be controlled at 20%;

[0029] 3. Put the high-grade sun-dried green tea after the tide into a nylon mesh bag, and tie up the mouth of the bag;

[0030] 4. Put the bagged high-grade tea on the middle layer above the bottom 30cm of the mother heap, and completely wrap the tea bags with the tea leaves of the mother heap;

[0031] 5. Every time the mother heap is turned over in the future, each bag of tea is taken out, deblocked and turned over, and then packed into the mother heap, and the moisture content and sensory evaluation are carried out at the same time. When it comes out of the heap, it will be unblocked after being out o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com