Periodic peristaltic agitation method

A stirring method and periodic technology, applied in biochemical equipment and methods, biochemical instruments, enzymology/microbiology devices, etc., to achieve the effects of improving reaction efficiency, simple structure, and enhancing heat and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

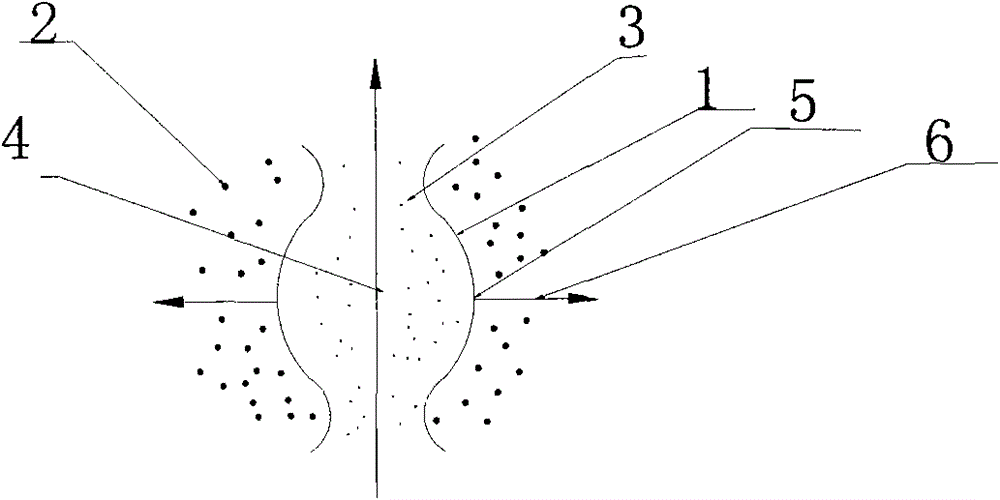

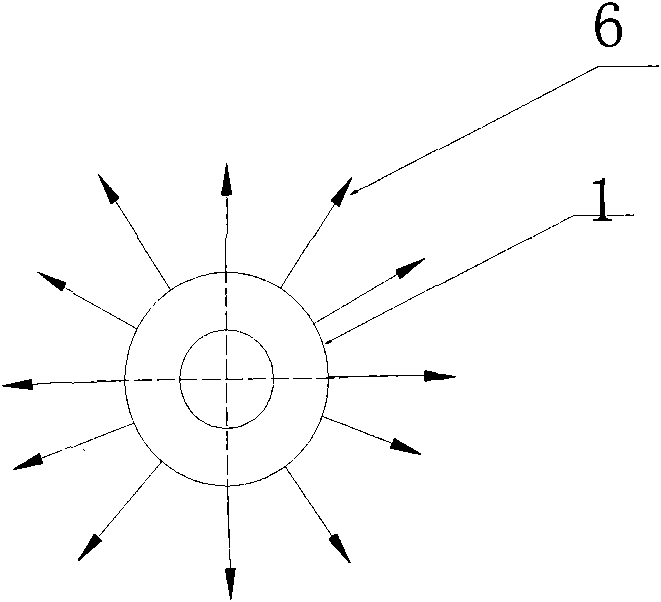

[0034] Embodiment 1: The peristaltic stirring method is applied to the solid-state fermentation of starchy raw materials for ethanol

[0035] In a 50L horizontal solid-state fermentation reactor, four peristaltic devices are evenly distributed on the side wall. Inside each device are small steel balls distributed unevenly. The radius of the rigid ball is 5-15cm. On the moving peristaltic rod, the elastic material in the peristaltic device is latex material produced according to the mold, and the material in the reactor is liquefied and saccharified starchy sweet potato. Movement in the opposite direction; the movement speed of the peristaltic rod is 1m / s, and the movement cycle interval is 5min, which makes the latex material periodically expand and contract, thereby promoting the periodic peristalsis of the material in the reactor; Compared with the fermentation of the peristaltic device, the fermentation time was shortened by 6 hours, and the utilization rate of starch was i...

Embodiment 2

[0036] Embodiment 2: peristaltic stirring method is applied to plant cell culture

[0037] In a 25L vertical reactor, add two tubular peristaltic devices. The elastic material in the peristaltic device is a silicone material produced according to the mold. The tubular peristaltic device is periodically fed with air with pressure; The latex material of the peristaltic device expands to a maximum volume of 2.5L. In this state, the reactor is filled with culture fluid and nutrient salts, etc., to cultivate comfrey cells; after starting, adjust the air pressure so that the peristaltic device The cycle of air stamping and pressure relief is 30 minutes, and the stamping maintenance time is 5 minutes, which makes the silica gel material periodically expand and contract, thereby promoting the periodic peristalsis of the material in the reactor; after the end of the culture, the cell yield (dry matter) can reach 10g / L.

Embodiment 3

[0038] Embodiment 3: peristaltic stirring method is applied to animal cell culture

[0039]In a 30L vertical reactor, a threaded peristaltic device is added. The elastic material in the peristaltic device is a gel material produced according to the mold. This gel material can expand and contract according to the pH change of the liquid in the device; by adjusting the external inflow The PH value of the liquid makes the latex material of the peristaltic device expand to a maximum volume of 1.5L. In this state, the reactor is filled with materials, culture medium and nutrient salts are added to carry out cell culture; after starting, adjust the air pressure to make the circulation The cycle of air stamping and pressure release into the peristaltic device is 20 minutes, and the stamping maintenance time is 2 minutes; the gel material is periodically expanded and contracted, thereby promoting the periodic peristalsis of the material in the reactor; after the end of the culture, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com