A highly sensitive five-degree-of-freedom array tactile sensor

A tactile sensor, degree of freedom technology, applied in the field of sensors, can solve the problem of low tangential detection sensitivity, and achieve the effects of high spatial force detection, high spatial resolution, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

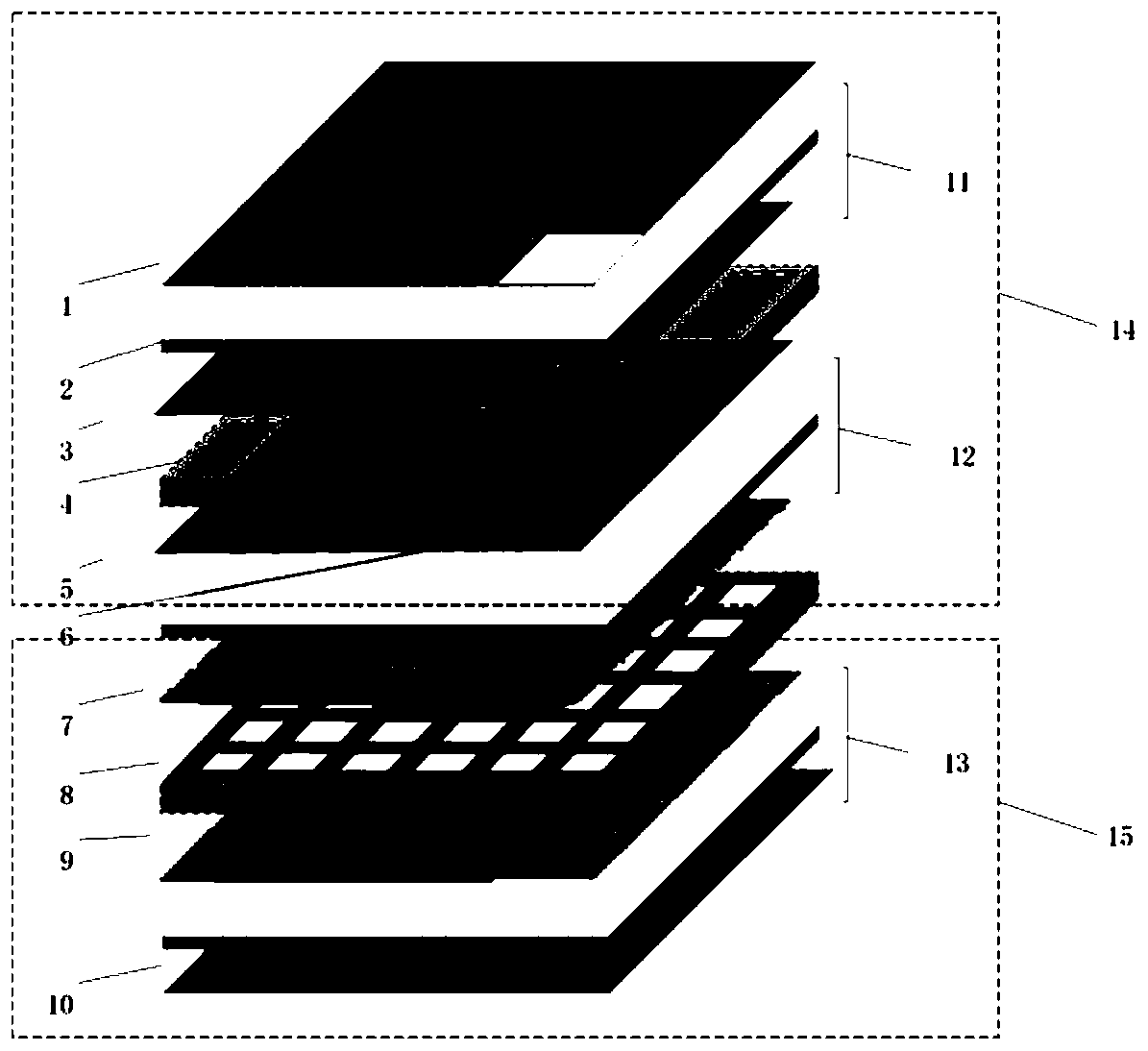

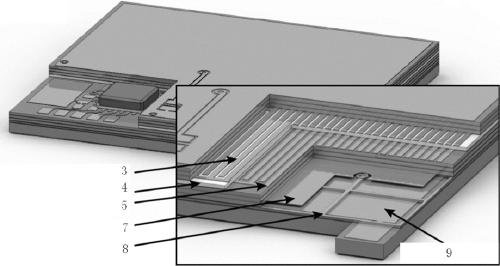

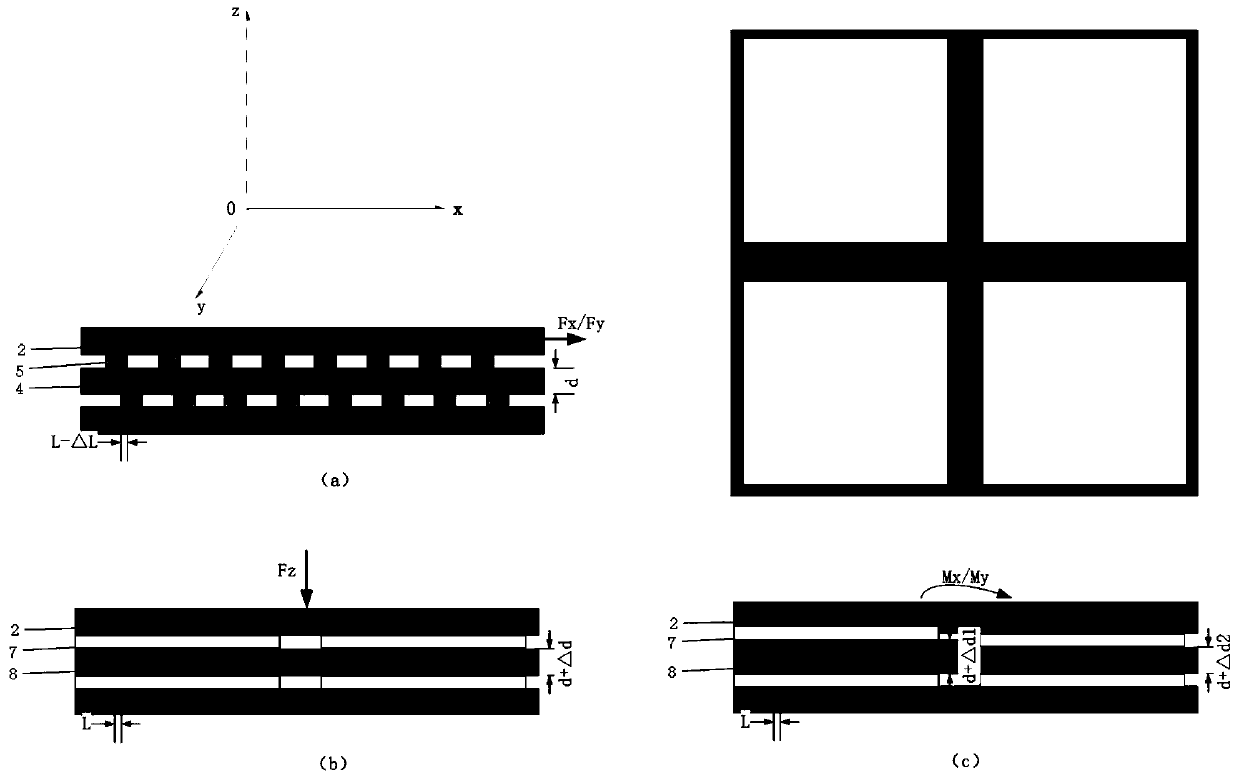

[0033] Such as figure 1 As shown, this implementation example is based on a high-sensitivity five-degree-of-freedom array tactile sensor, which mainly consists of an upper printed circuit board 11, a shear dielectric layer 4, an intermediate printed circuit board 12, a forward dielectric layer 8, and a lower printed circuit board 13. Composed layer by layer. The sensor is based on the capacitive working mechanism. The middle printed circuit board is used as a fixed electrode, and the upper and lower printed circuit boards are respectively used as positive pressure / tangential force movable plates. Due to the external force, the sensor will cause changes in the capacitance structure parameters of the sensor. By measuring the capacitance change, the positive pressure Fz, tangential force Fx / Fy and moment Mx / My acting on the sensor can be sensed. The working principle is shown in the figure figure 2 shown.

[0034] The tactile sensor is under the action of tangential force Fx / F...

example 2

[0040] Such as Figure 4 As shown, the tactile sensor in the left figure shows the lower panel structure of the middle layer printed circuit board of the sensor, and this patent is set to N×N total N 2 A rectangular exposed electrode plate, output N 2 The digital-to-analog conversion is realized through the digital conversion chipset, and the serial port transmission method is used to transmit the data to the single-chip microcomputer for data packaging processing. The array sensor transmission signal is packaged into a data set formed by multiple frames of tactile pressure image data, and then transmitted to the PC. Realize the signal display, and finally realize the array pressure detection of the tactile sensor.

[0041] Among them, the lower panel structure of the middle layer printed circuit board of the tactile sensor is to realize N 2 block the signal output of the exposed electrodes, taking into account the N 2 Due to the difficulty of signal routing, it is planned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com