Method for reducing chlorite as disinfection by-product of drinking water

A technology for disinfection by-products and chlorite, which is applied in chemical instruments and methods, neutralized water/sewage treatment, oxidized water/sewage treatment, etc. The problems of large dosage and troubles in water plants can improve the safety of water quality and reduce the content of chlorite.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 A water plant in Shenzhen City reduces the treatment method of disinfection by-product chlorite in the factory water

[0028] Raw water situation

[0029] The raw water is reservoir water, and the water source is subject to organic pollution. It belongs to Class III surface water quality, with an average turbidity of 14.03 NTU, a maximum manganese content of 0.46 mg / L, and an average of 37.2 million algae cells per liter. It has obvious high algae and low Features of turbidity and organic micro-pollution.

[0030] Chlorine Dioxide Preparation

[0031] Using the complete set of equipment from Shenzhen Suriman Company, the preparation method is as follows: sodium chlorate, sulfuric acid (70% concentration by mass) and hydrogen peroxide (50% concentration by mass) are mixed and reacted to prepare chlorine dioxide (gaseous state, purity 95%) %).

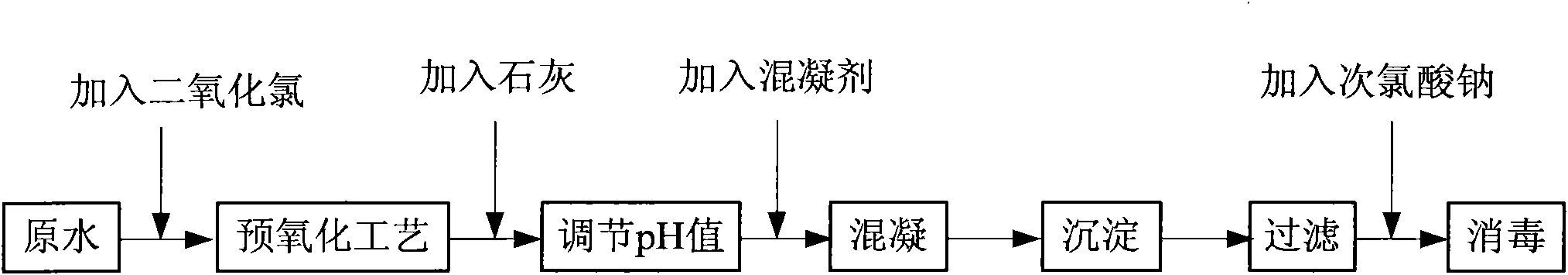

[0032] figure 1 For the present invention reduces the method flowchart of drinking water disinfection by-produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com