A device for preparing disinfectant nanoparticles

A nanoparticle and disinfectant technology, applied in the direction of disinfectants, chemicals for biological control, biocides, etc., can solve the problems of large disinfectant particles that cannot achieve disinfection effect, high disinfectant concentration, and enhanced corrosiveness. To achieve the effect of improving disinfection and sterilization, reducing corrosion and reducing corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

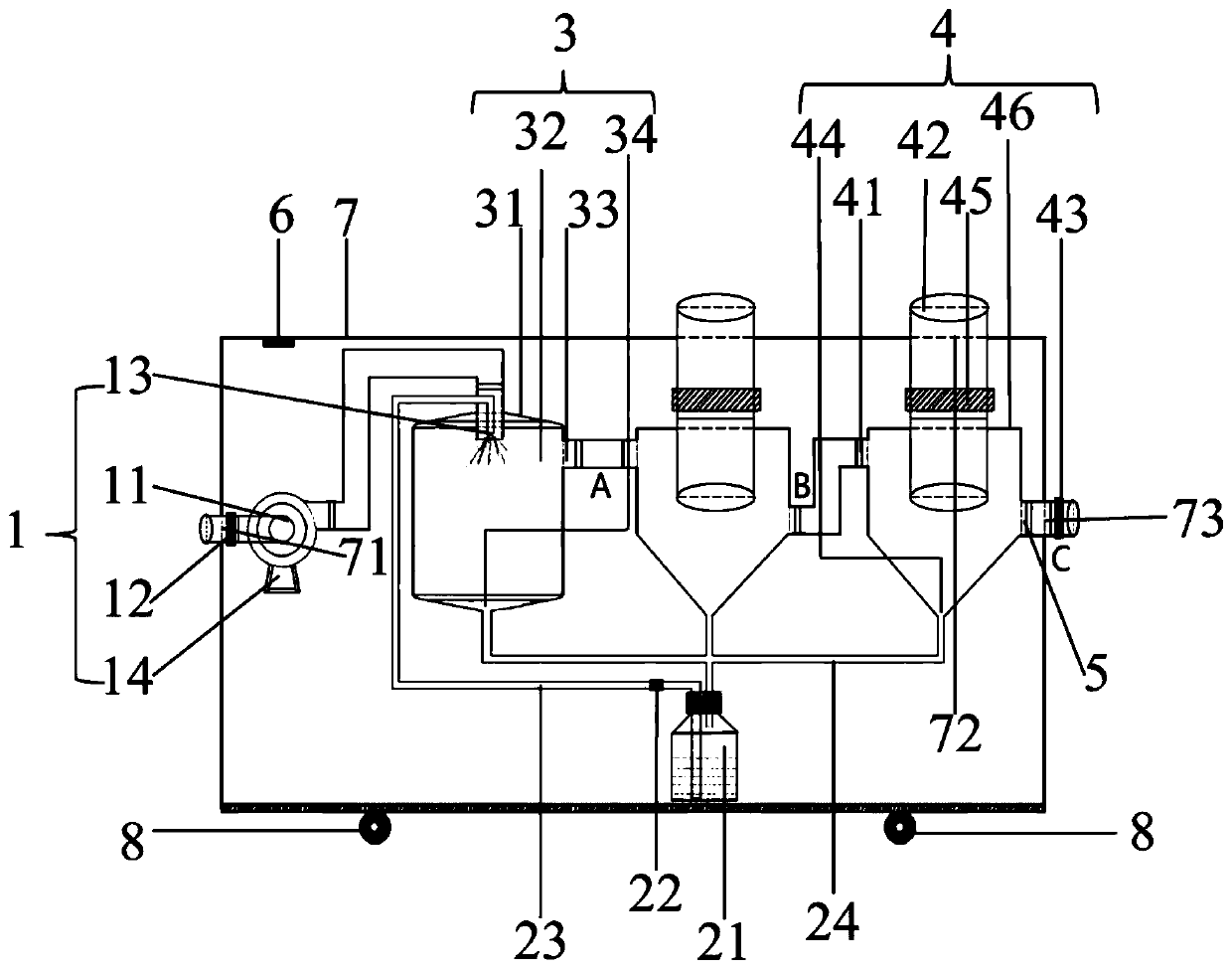

[0055] like figure 1 As shown, the present application provides a device for preparing disinfectant nanoparticles by vaporizing and separating disinfectant under low temperature conditions, the device includes a spray system 1 for atomizing the disinfectant to form small particles, and a The liquid storage device 21 is used for the vaporization separation system 3 for separating and vaporizing the atomized small particles of the disinfectant to form smaller particles (nano-mist), and for drying and separating the formed nano-mist after the separation and vaporization. The cyclone separation system 4. The liquid storage device 21 is respectively connected with the spray system 1 , the vaporization separation system 3 and the cyclone separation system 4 . The spray system 1 , the vaporization separation system 3 and the cyclone separation system 4 are connected in sequence. The liquid storage device 21 is connected to the vaporization separation system 3 and the cyclone separa...

Embodiment 2

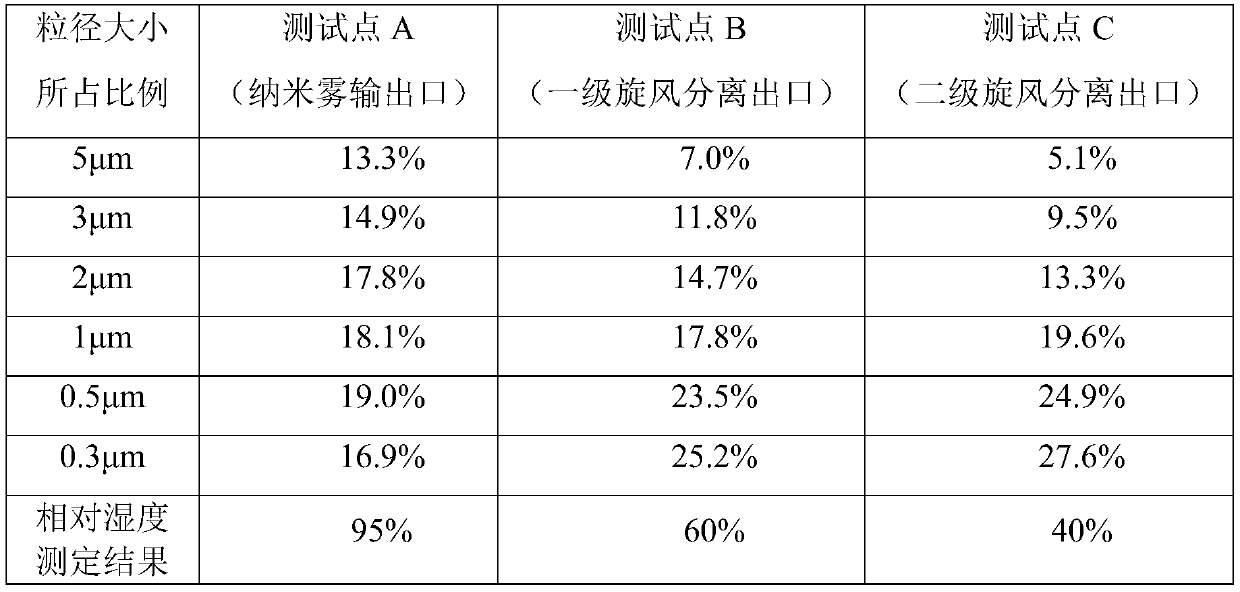

[0069] Practical analysis using experimental operation

[0070] 1. Determination of particle size distribution and drying effect

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com