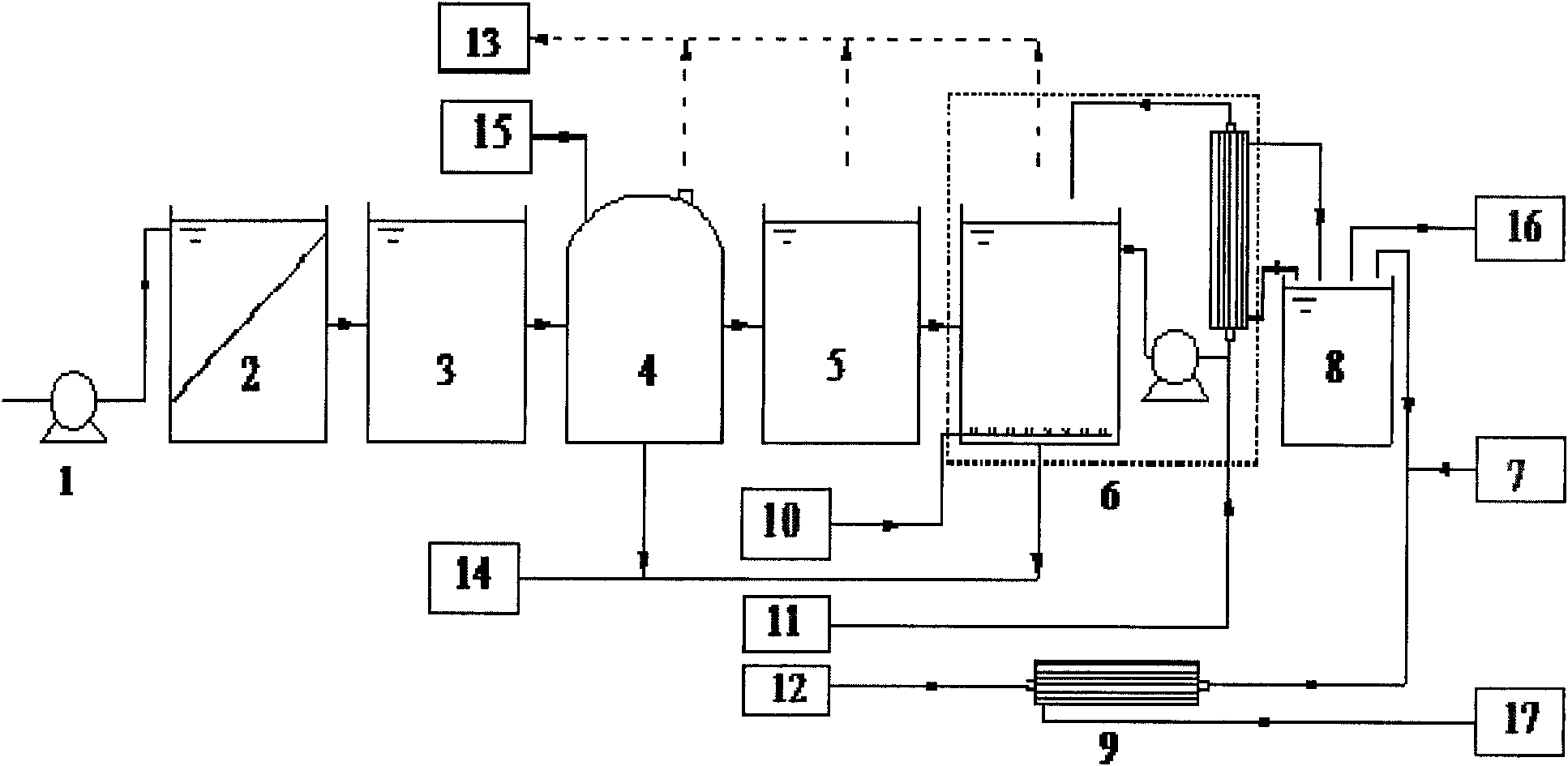

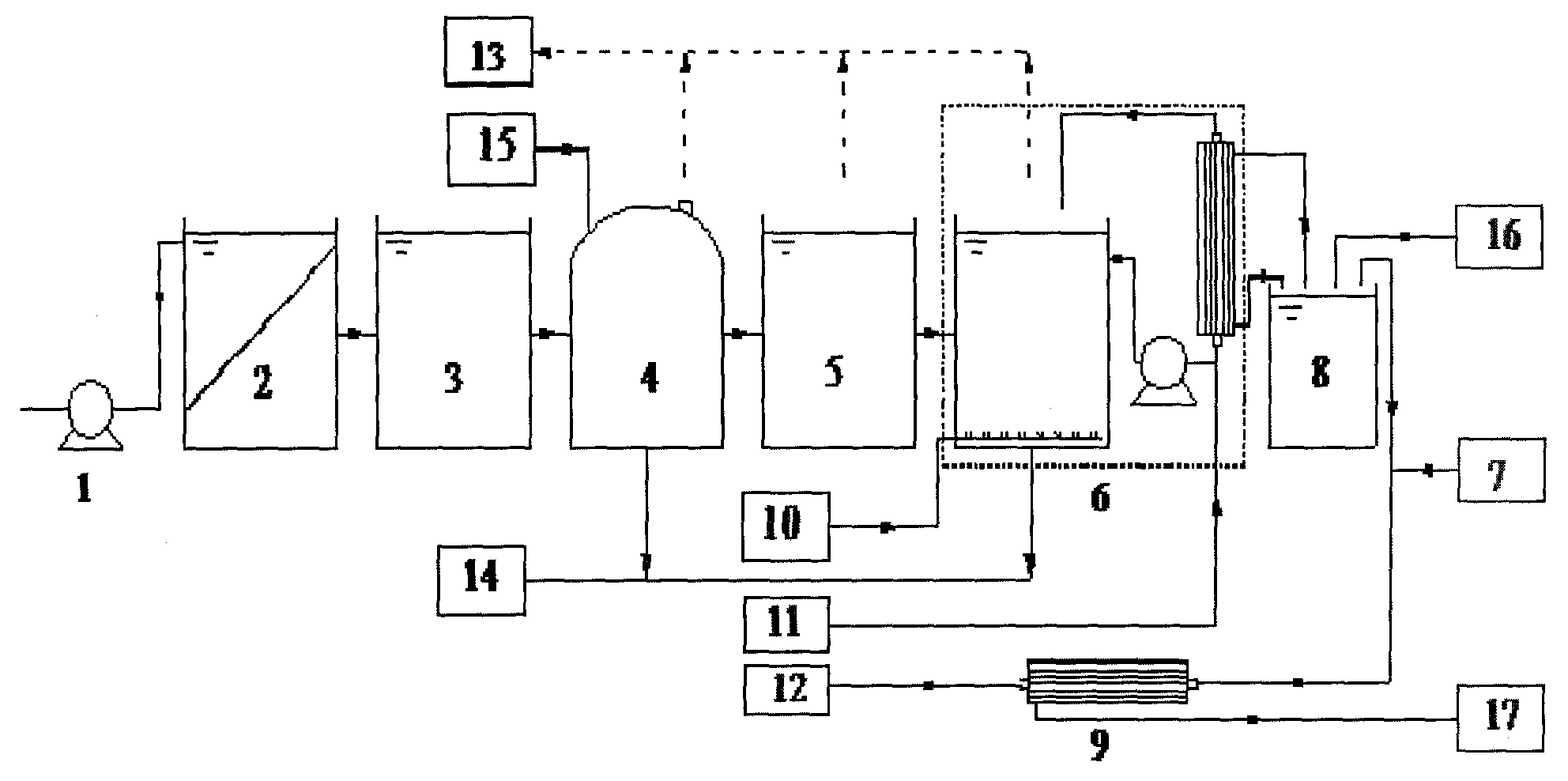

Method and device for treating and recycling tobacco wastewater with double-membrane process

A double-membrane method and wastewater technology, which is applied in chemical instruments and methods, wastewater treatment in processing, flotation water/sewage treatment, etc., can solve the problems of large footprint, general effluent quality, and complex operation, and achieve the goal of occupying an area The effect of small area, easy automatic operation and control, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Example 1: the source of sewage is waste water from a cigarette factory in a certain city, and the water quality conditions are: CODcr: 400~2500mg / L, SS: 100~300mg / L, chroma: 30~300 times, design process of the present invention is carried out to tobacco waste water Processing, processing capacity 2000m 3 / d, after advanced oxidation, MBR effluent reaches the water quality standard stipulated in "Urban Sewage Recycling Urban Miscellaneous Water Quality" (GB 18920-2002), reused for greening and toilet flushing, reverse osmosis effluent water quality meets "Industrial Boiler Water Quality" ( GB 1576-2001) and "Circulating Cooling Water Quality" (GB 50050-95) stipulated water quality standards, used as boiler make-up water and air-conditioning circulating cooling water.

example 2

[0033] Example 2: The source of sewage is waste water from a certain cigarette factory, and the water quality conditions are: CODcr: 400~1000mg / L, SS: 100~300mg / L, chroma: 30~300 times, design process of the present invention carries out to the sewage of cigarette factory Processing, processing capacity 1000m 3 / d, after disinfection, the MBR effluent meets the water quality standards stipulated in the "Urban Sewage Recycling and Utilization of Urban Miscellaneous Water Quality" (GB 18920-2002), and the reverse osmosis effluent water quality meets the "Industrial Boiler Water Quality" (GB 1576-2001) and "Circulating Cooling The water quality standard stipulated in "Water Quality" (GB50050-95).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com