Melt-down non-woven material, preparation method and product

A non-woven material and melt-blown technology, applied in the field of non-woven materials, can solve the problems that cannot meet the requirements of mask resistance, efficiency, anti-hemodialysis and antibacterial properties at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] According to the conventional melt-blown process, the polymer used is polypropylene chips; after the polypropylene chips are fed and melt-extruded, in the process of fiber formation, a stream containing nano-tourmaline powder is introduced from both sides of the hot air flow These nano-tourmaline powders are mixed with polypropylene microfibers that are being thinned in the hot air flow. At the same time, under the hot air flow, the solution containing chitosan derivatives is atomized and sprayed evenly On the polypropylene superfine fiber, these substances are sprayed to the net-forming chain at the same time, condensed into a net, and the hot air or part of the water vapor is sucked away through the suction at the bottom of the net, and then passed through a drying roller with a temperature not exceeding 100 degrees and a cold water stick , and then rolled into cloth.

[0040] Wherein weight ratio, polypropylene: tourmaline powder: chitosan derivative=94: 3: 3;

[00...

Embodiment 2

[0044] According to the conventional melt-blown process, the polymer used is polypropylene chips; after the polypropylene chips are fed and melt-extruded, in the process of fiber formation, a stream containing nano-tourmaline powder is introduced from both sides of the hot air flow These nano-tourmaline powders are mixed with polypropylene microfibers that are being thinned in the hot air flow. At the same time, under the hot air flow, the solution containing chitosan derivatives is atomized and sprayed evenly On the polypropylene superfine fiber, these substances are sprayed to the net-forming chain at the same time, condensed into a net, and the hot air or part of the water vapor is sucked away through the suction at the bottom of the net, and then passed through a drying roller with a temperature not exceeding 100 degrees and a cold water stick , and then rolled into cloth.

[0045] Wherein the weight ratio is polypropylene: tourmaline powder: chitosan derivative=91:6:3;

...

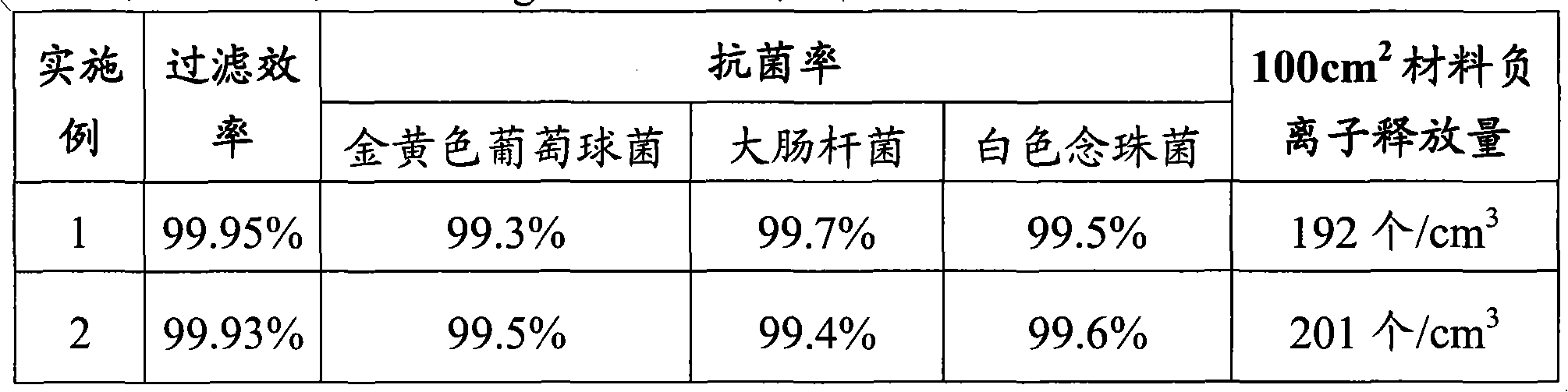

experiment example

[0049] The melt-blown nonwoven material prepared by the above-mentioned embodiment 1 and embodiment 2 was subjected to a filter efficiency detection experiment, an antibacterial detection experiment and an anion release test experiment by conventional methods. The results show that while the resistance is controlled within 5 mm of water column, the filtration efficiency can reach more than 99.9%, and the anti-hemodialysis can reach 160 mmHg, as shown in the following table:

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com