Vibration isolating support structure of damping spring floating track bed and installation method thereof

A technology of floating ballast bed and damping spring, which is applied to roads, tracks, buildings, etc., can solve the problems of uneven damping effect, high processing cost, and large steel consumption, so as to achieve convenient installation and operation, improve emergency safety, The effect of saving the amount of damping agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

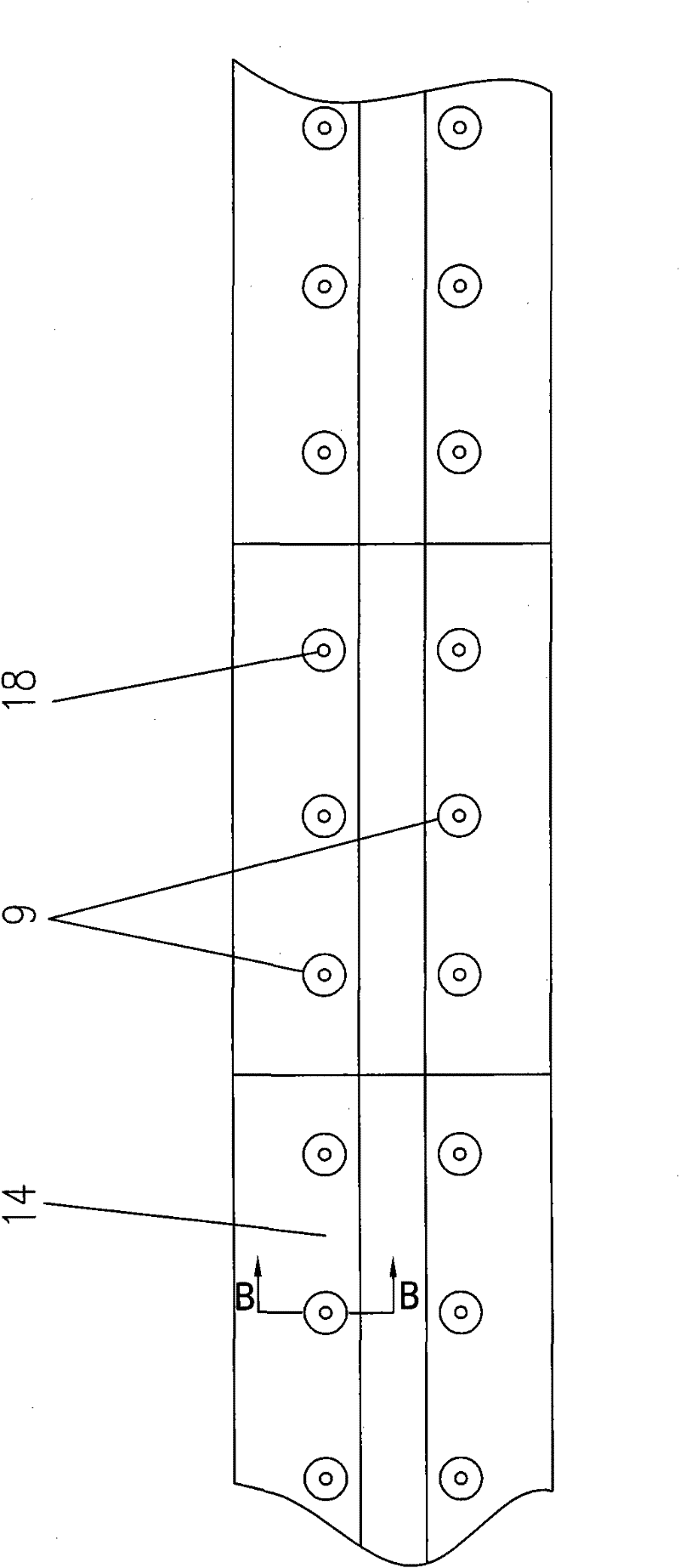

[0058] like figure 1 As shown in the schematic diagram of the structure of the damping spring floating track bed of the present invention, the floating slab track bed includes a plurality of interconnected bed bodies 14 and a plurality of pre-embedded sleeves 9 arranged on the bed body 14. The pre-embedded sleeves 9 and the bed body 14 connected as one. A vibration isolator 10 is arranged in each embedded sleeve 9, so as to realize the support and vibration reduction of the entire floating slab track bed.

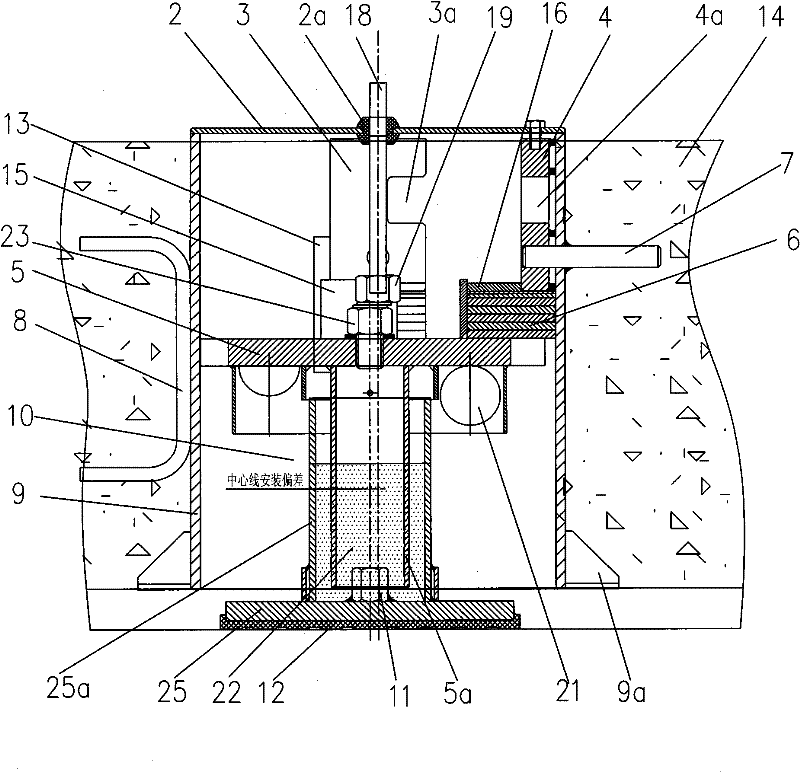

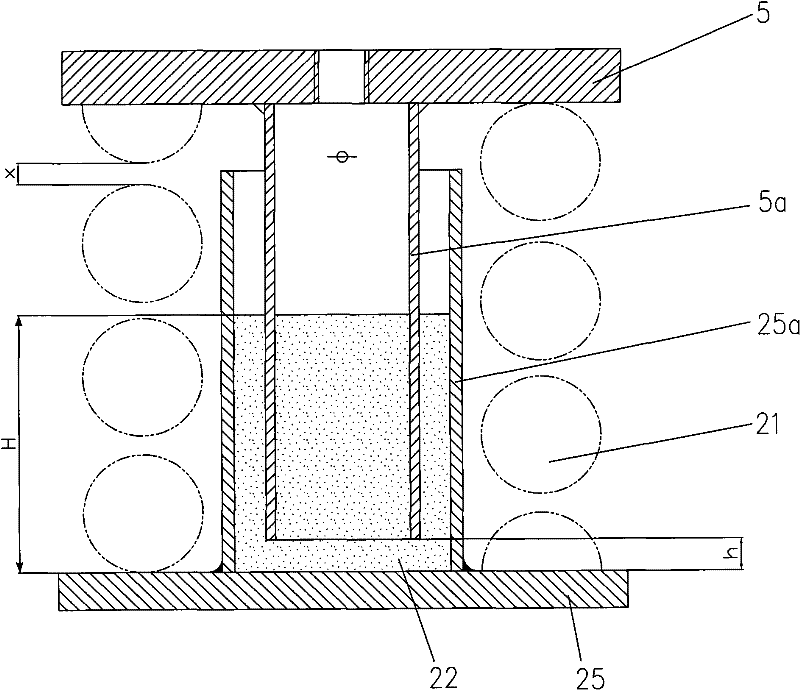

[0059] like figure 2 , 3 shown, where figure 2 It is a sectional view of the vibration isolation support structure of the floating slab track bed of the present invention, image 3 It is a top view of the vibration isolation support structure of the floating slab track bed of the present invention. The upper part of the inner circumferential wall of the pre-embedded sleeve 9 is evenly distributed in the same plane with three bearing bosses 3, 4, and 17 fixed integral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com