Heat conductivity measuring device and method

A technology of thermal conductivity and measuring device, which is applied in the field of thermophysical property measurement, can solve problems such as not fundamentally eliminating system errors, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

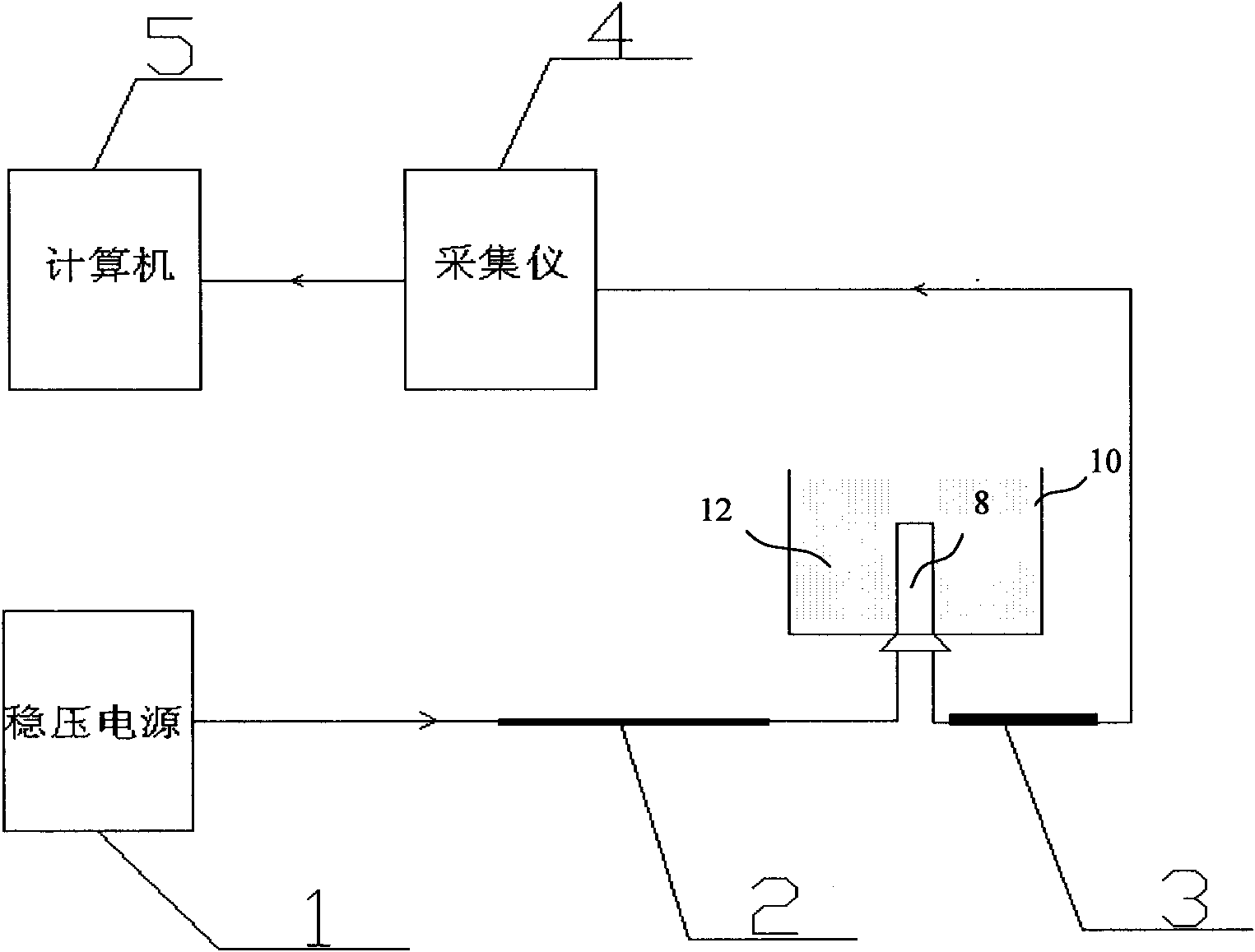

Method used

Image

Examples

Embodiment 1

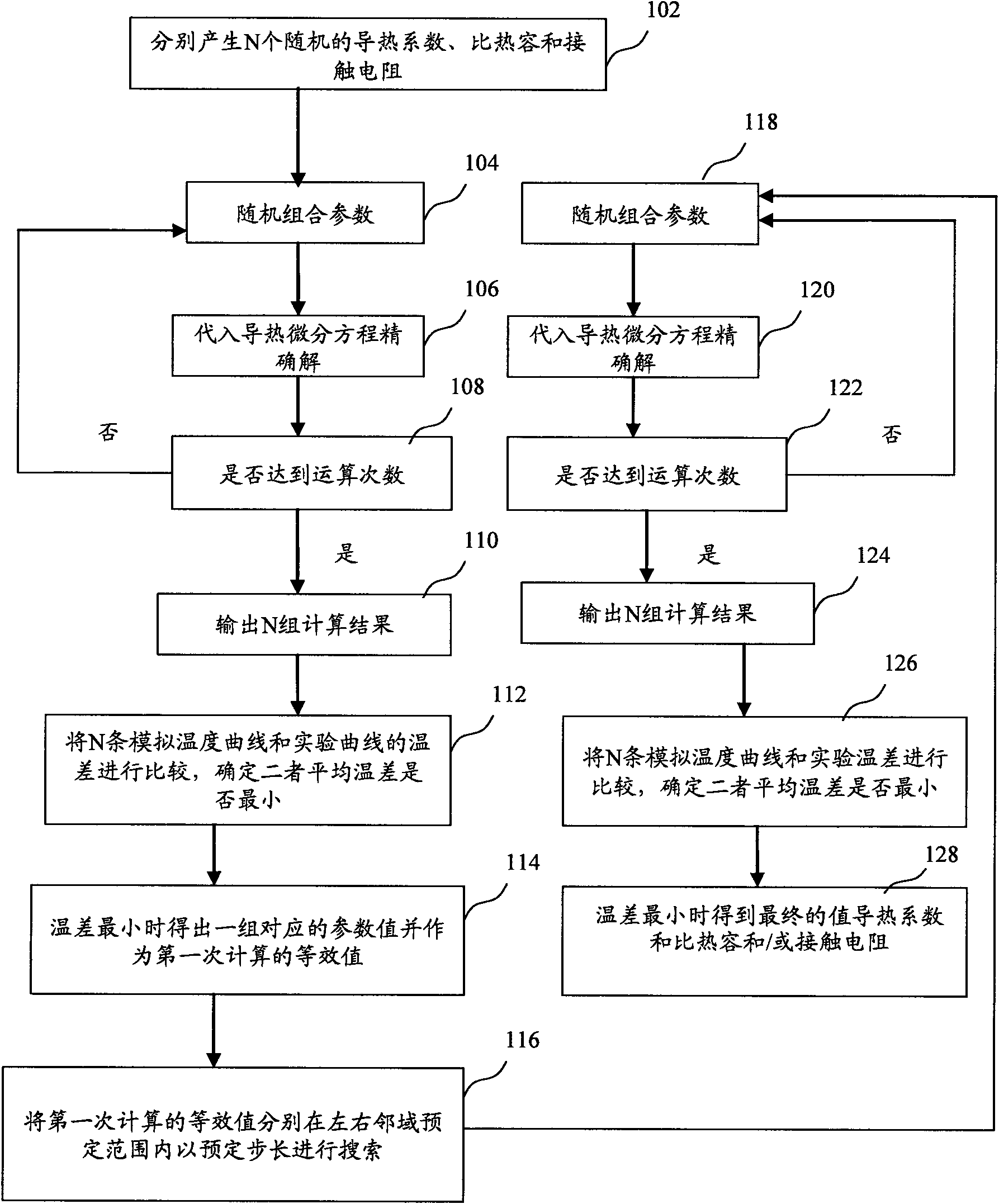

[0051] Step 1. First, determine an assumed "specific heat capacity c p "And "contact thermal resistance R". Here specific heat capacity c p The value range of , for example, is between 0 and 5, and the contact thermal resistance R for liquids can be between -0.05 and 0.05, the contact thermal resistance R for solids, such as sand, can be between 0 and 0.6, and the soil can be It takes a value between 0 and 3. . Here, for different samples to be tested, the value range of the specific heat capacity and / or contact thermal resistance can be appropriately set by those skilled in the art, and the present invention is not limited to the above specific examples.

[0052] In addition, a certain number of random numbers subject to uniform distribution are generated, which are respectively used as the values of "thermal conductivity λ". Here, various suitable algorithms such as the multiplication congruence method and the mixed congruence method can be used to generate random value...

Embodiment 2

[0062] Step 1. First, determine a hypothetical "contact thermal resistance R". Here, the value range of the contact thermal resistance R can be properly set in the manner described in the above-mentioned embodiment 1. And, use the multiplication and congruence method to generate a certain number of random numbers that obey the uniform distribution, which are respectively used as "thermal conductivity λ" and "specific heat capacity c p " value.

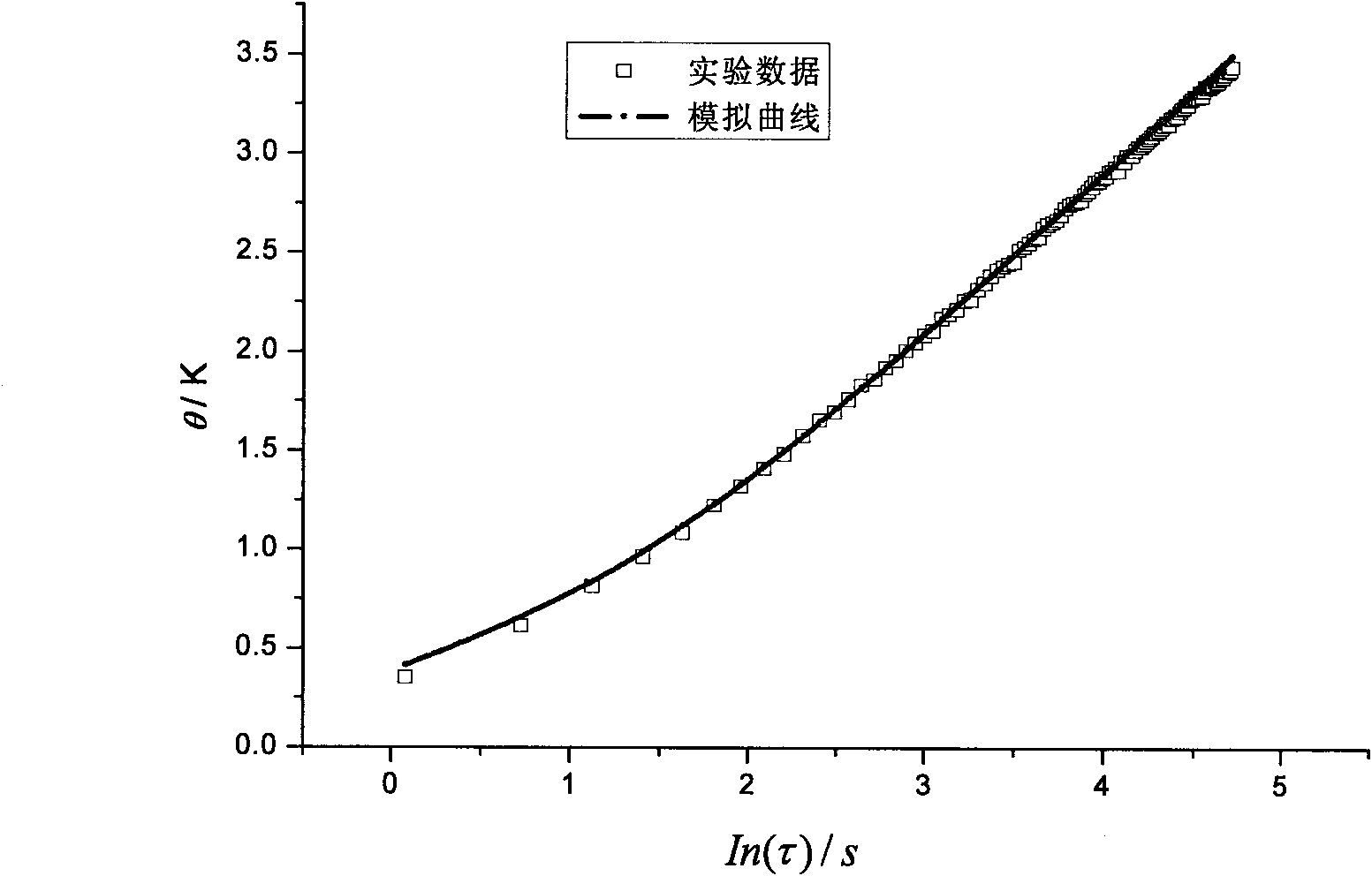

[0063] Then, after combining the two according to the Latin hypercube sampling method, they are substituted into the exact solution of the heat conduction differential equation represented by formula (1), and a set of most suitable "λ" and "c p " value, so that the average temperature difference between the numerical simulation curve obtained at this time and the experimental curve at each time point is the smallest, and this group of "λ" and "c p ” value as the equivalent thermal conductivity and equivalent specific heat capacity in ...

Embodiment 3

[0066] Step 1. First, use the multiplication and congruence method to generate a certain number of random numbers subject to uniform distribution, which are respectively used as "thermal conductivity λ" and "specific heat capacity c p " and "Contact thermal resistance R" values, these three sets of random values are combined according to a certain combination method, such as the Latin hypercube sampling method, and then substituted into the exact solution of the thermal probe heat conduction differential equation represented by formula (1), from which Select a set of most suitable "λ", "c p " and "R" value, so that the average temperature difference between the numerical simulation curve obtained at this time and the experimental curve at each time point is the smallest, and the set of "λ", "c p " and "R" value as the equivalent value in the first calculation.

[0067] Step 2, similar to the above-mentioned embodiments 1 and 2, search systematically in an organized manner a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com