Light scattering multilayered structure and manufacturing method thereof

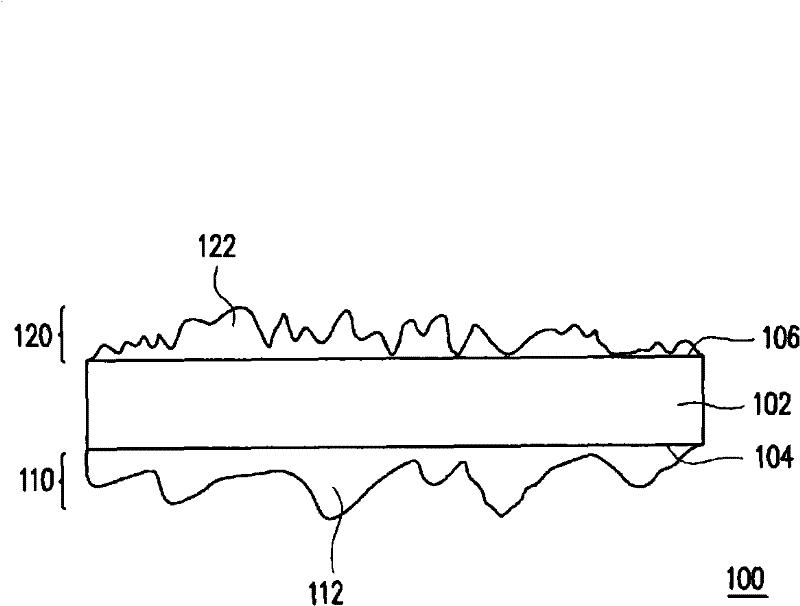

A technology of multi-layer structure and manufacturing method, applied in the direction of final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve the problems of rough surface undulation, unfavorable silicon layer growth, poor characteristics of solar cell elements, etc., to achieve growth Dead time and path, effect of increasing short-circuit current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

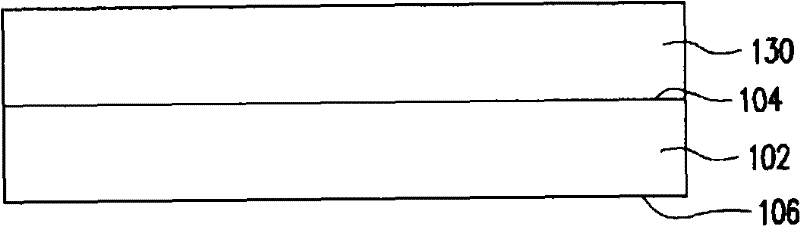

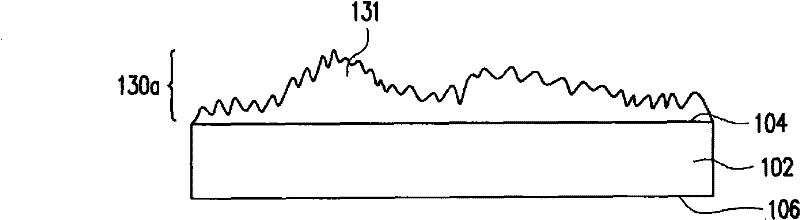

[0069]In order to compare the influence of the light scattering multilayer structure of the present invention and the traditional transparent conductive layer having a protruding structure on the scattering ability of light, Experimental Example 1 (i.e. the light scattering multilayer structure of the present invention) and Experimental Example 2 (i.e. The light-scattering multilayer structure of the present invention), a comparative example, and a conventional transparent conductive layer, wherein the conventional transparent conductive layer is a stacked Asahi TCO substrate on a glass substrate. Firstly, experimental example 1 was made, a first zinc oxide layer with a thickness of 1 micron was formed on the upper surface of the glass substrate, and the first zinc oxide layer was etched with HCl etching solution for 20 seconds. Next, a second zinc oxide layer with a thickness of 1 micron is formed on the lower surface of the glass substrate, and the second zinc oxide layer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com