Soda biscuit and production method thereof

A technology of soda biscuits and baking soda, which is applied in pre-baking dough processing, baking, dough processing and other directions, can solve the problems of long production cycle and inconvenient operation, and achieve the effect of improving flavor and taste, and improving nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

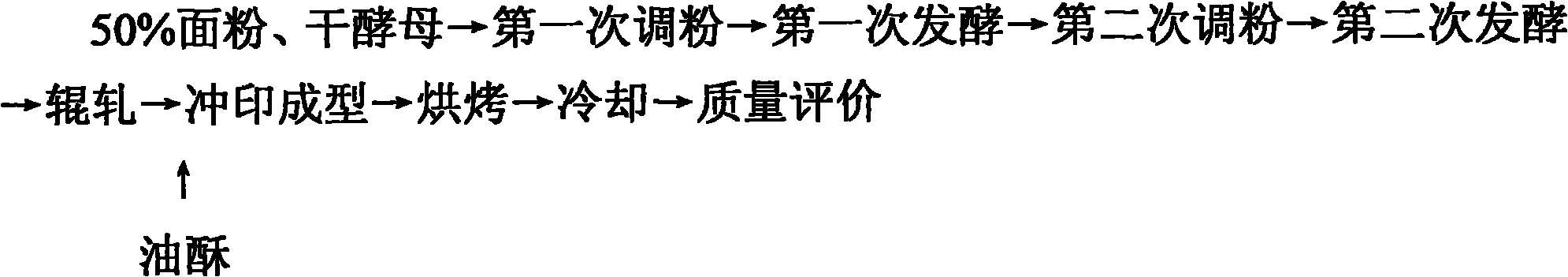

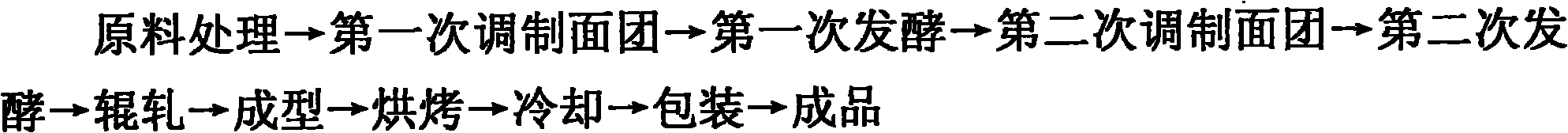

Method used

Image

Examples

Embodiment 1

[0049] Preparation of direct-throwing lactic acid bacteria starter

[0050] (a) Inoculate the lactic acid bacteria strains into the liquid medium (the composition of the medium is shown in Table 1 below) and carry out two expansion cultivations, the first expansion cultivation: inoculate 10 in 8 liters of seed tanks. 5 cfu / ml of lactic acid bacteria, cultivated to 109 cfu / ml, the culture condition is temperature 37°C, time 8 hours; the second expansion culture: inoculate all the lactic acid bacteria in the 8-liter tank into the 200-liter pilot test tank and cultivate to 10 10 cfu / ml, the culture condition is temperature 37℃, time 24 hours;

[0051] (b) Obtain the bacterium pellet by centrifugation, the centrifugation condition is 16000r / min, 30min;

[0052] (c) Prepare trehalose solution with a concentration of 20% (w / w) with water twice the amount of bacterial cell sedimentation, sterilize at 90°C / 25min, cool to 25°C, add trehalose solution In the bacterial cell precipitati...

Embodiment 2

[0058] Preparation of direct-throwing lactic acid bacteria starter:

[0059] (a) Inoculate the lactic acid bacteria into the liquid medium (the composition of the medium is shown in Table 1) and carry out two expansion cultures, the first expansion culture: inoculate 10 liters of lactic acid bacteria in a seed tank of 8 liters. 6 cfu / ml of lactic acid bacteria, cultivated to 10 10 cfu / ml, the culture condition is temperature 37 ℃, time 12 hours; the second expansion culture: inoculate all the lactic acid bacteria in the 8 liter tank into the 200 liter pilot test tank and cultivate to 10 11 cfu / ml, the culture condition is temperature 37℃, time 30 hours;

[0060] (b) Obtain the bacterium pellet by centrifugation, the centrifugation condition is 16000r / min, 60min;

[0061] (c) Prepare trehalose solution with trehalose concentration of 30% (w / w) with water twice the amount of cell sedimentation, sterilize at 95°C / 30min, cool to 30°C, and prepare seaweed The sugar solution is a...

Embodiment 3

[0065] Preparation of direct-throwing lactic acid bacteria starter:

[0066] (a) Inoculate the lactic acid bacteria strains into the liquid medium (the composition of the medium is shown in Table 1) and carry out two expansion cultures, the first expansion culture: inoculate 10 liters of lactic acid bacteria in a seed tank of 8 liters. 5 cfu / ml of lactic acid bacteria, cultivated to 10 10 cfu / ml, the culture condition is temperature 37 ℃, time 10 hours; the second expansion culture: inoculate all the lactic acid bacteria in the 8 liter tank into the 200 liter pilot test tank and cultivate to 10 10 cfu / ml, the culture condition is temperature 37℃, time 27 hours;

[0067] (b) Obtain bacterial cell pellet by centrifugation, the centrifugation condition is 16000r / min, 45min;

[0068] (c) Prepare trehalose solution with trehalose concentration of 25% (w / w) with water twice the amount of cell sedimentation, sterilize at 92°C / 28min, cool to 27°C, and prepare seaweed The sugar solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com