Multi-sensor feedback wire feed method

A wire feeding and sensing technology, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., to achieve precise control and improve welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

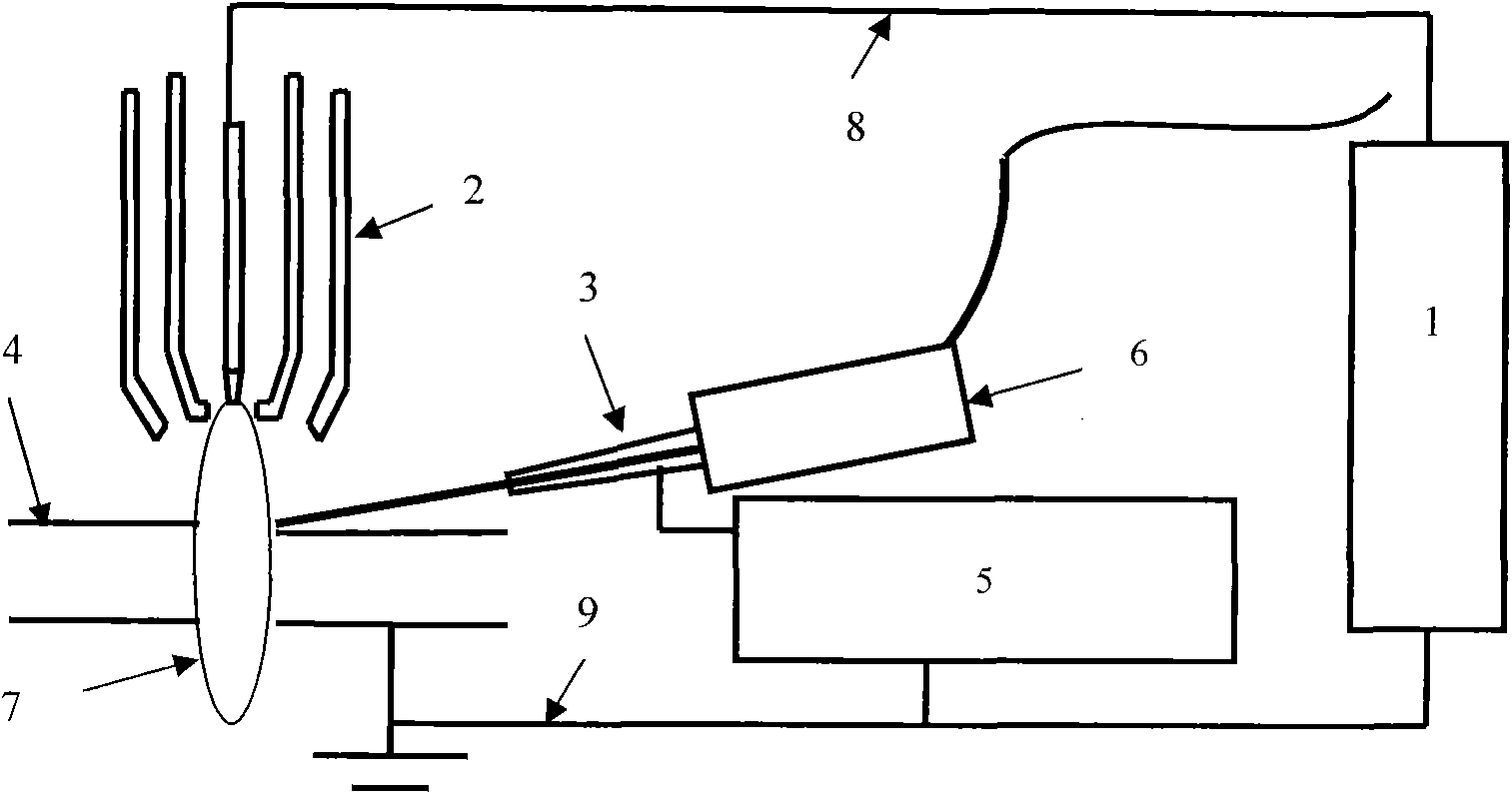

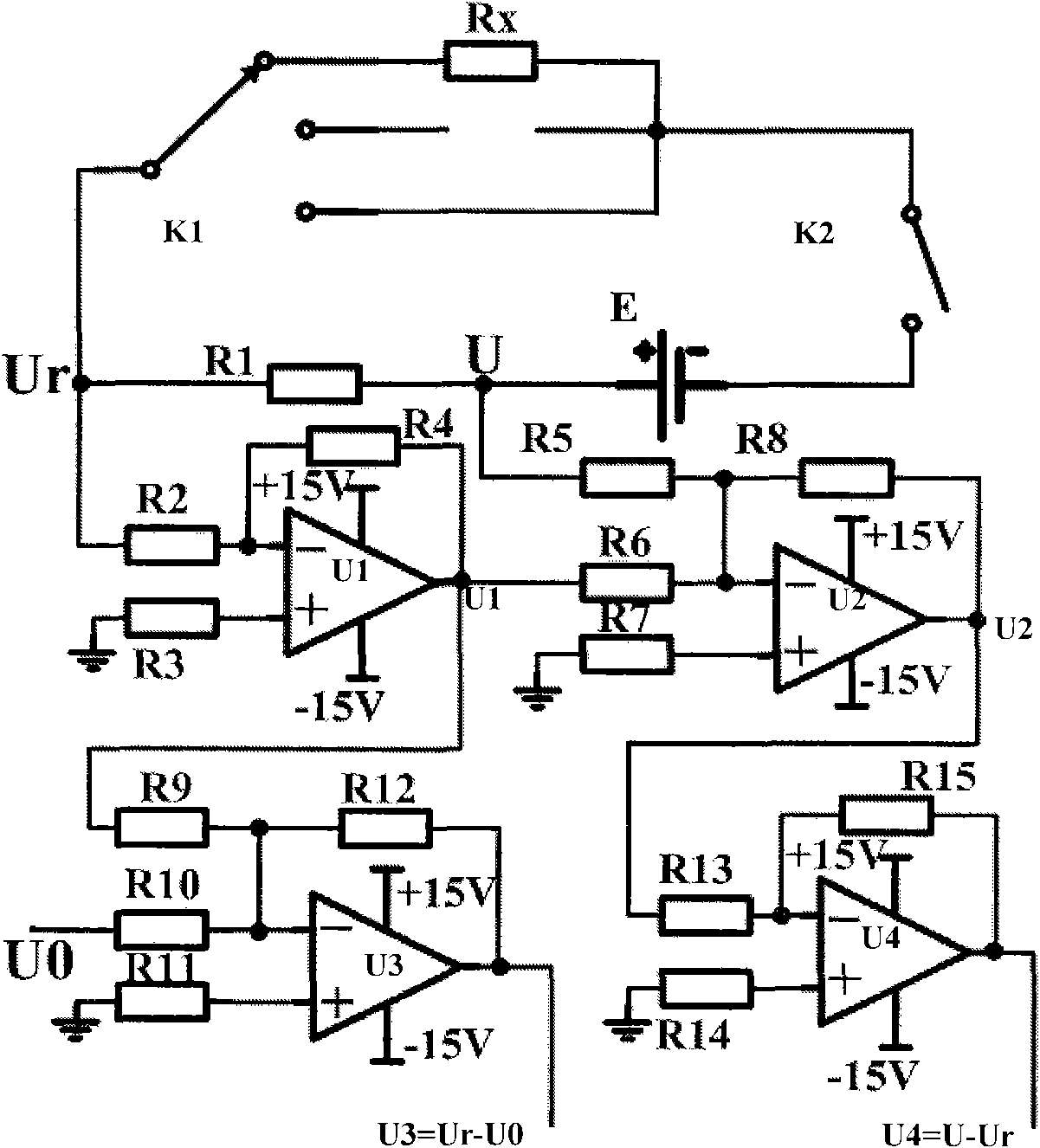

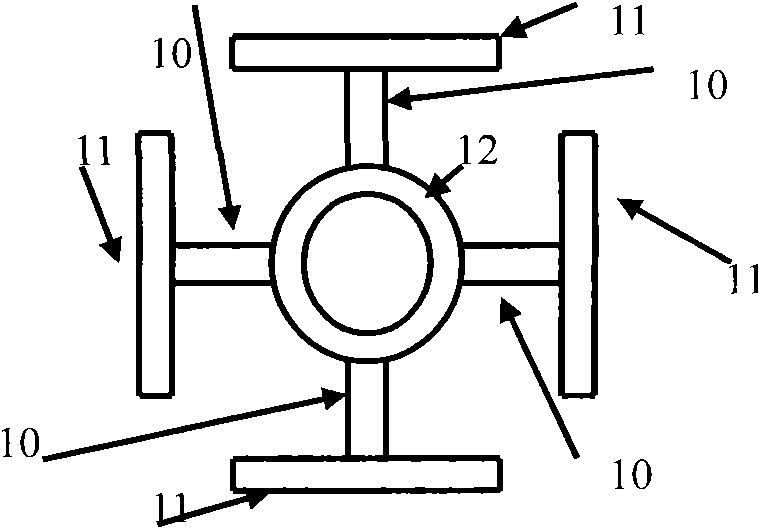

[0026] Embodiments of the present invention will be specifically described below with reference to the drawings. The structures and principles of the sensors used in the drawings are not limiting, but illustrative in nature. In the accompanying drawings, only the connection mode of the welding method related to the electric circuit is illustrated, and the necessary gas circuit and water circuit connection methods of the welding torch all use conventional connection methods, so no further description is given.

[0027] Below in conjunction with accompanying drawing, the step of this wire feeding method is described in detail:

[0028] (1) Preparation before welding

[0029] After installing the welding torch 2 and the workpiece 4 to be welded, the relative positions of the wire guide 3 and the welding torch 2 are fixed, and the welding power supply and its control system 1, the workpiece 4 to be welded and the welding torch 2 are connected through the welding cable 8, and chec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com