Lifting mechanism stroke control device, lifting machine and corresponding control method

A stroke control and hoist technology, applied in sequence/logic controller program control, electrical program control, elevator and other directions, can solve problems such as incorrect calculation of the stroke of the hoisting trolley, errors in the calculation of the stroke of the trolley, and endangering the safety of the hoisting trolley. , to solve the contradiction between running speed and accurate parking, achieve precise positioning, and improve the effect of running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

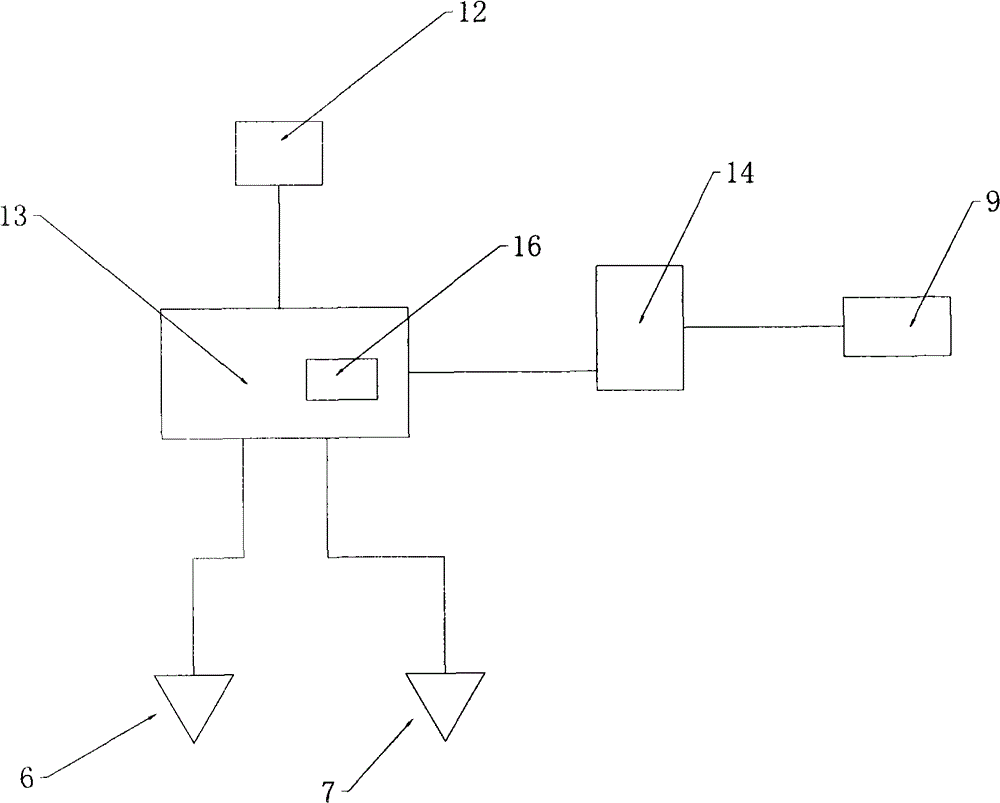

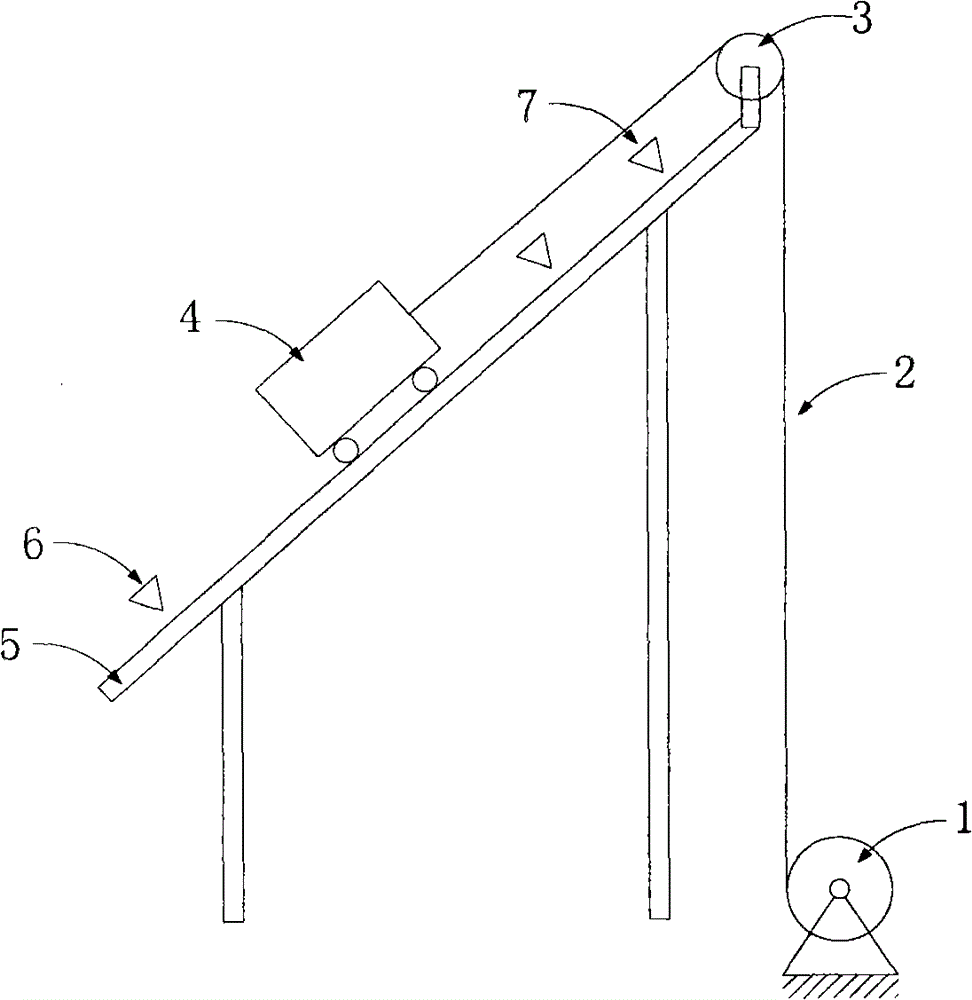

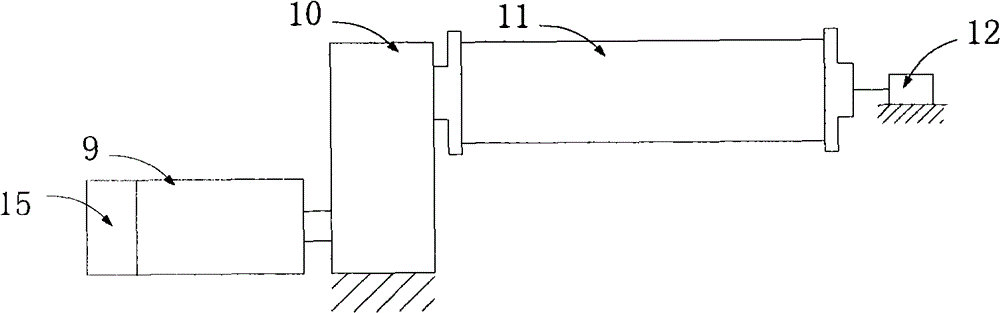

[0025] like figure 1 As shown, the hoist stroke control device according to the present invention has: a first position detection switch 6, a second position detection switch 7, a timer 16, an encoder 12, and a controller 13, wherein the controller 13 receives information from the first position The first position signal from the detection switch 6 , the second position signal from the second position detection switch 7 , the timing signal from the timer 16 , and the count signal from the encoder 13 . At the same time, the controller 13 is connected to the frequency converter 14 again. Wherein, the inverter 14 drives the hoisting motor 9 used as the driving device in the present invention to work, so that the hoisting motor 9 can run at different speeds under the control of the inverter 14, so as to realize the operation at different speeds. Purpose.

[0026] exist figure 2 A schematic diagram of a hoist according to the invention is shown schematically in . see figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com