Method for preparing room-temperature fast-curing addition organic silicon rubber

A silicone rubber, rapid vulcanization technology, applied in the chemical industry, can solve the problems of complicated process and slow room temperature vulcanization time, and achieve the effect of simple preparation method, good performance index and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The present invention prepares the method for the organosilicon rubber of addition type rapid vulcanization at room temperature, first adds 25 parts of ethylene oils, 8 parts of white carbon black, 10 parts of silica gel to the reactor equipped with stainless steel stirrer, motor and heating system, Mix 2 parts of hydroxyl silicone oil, 40 parts of methyl vinyl silicone rubber, and 15 parts of liquid paraffin at room temperature, then raise the temperature to 150 ° C for 2 hours; after evacuating for 1 hour, discharge the material, and then filter to obtain the base rubber .

[0020] The filtered base glue is divided into two parts. Add 3 parts of platinum catalyst to 50 parts of base glue and stir evenly to form component A; add 5 hydrogen-containing silicone oil to 50 parts of base glue and stir evenly to form component B; , Mix A and B evenly, and vulcanize quickly in 5 minutes.

[0021] The ethylene oil in the raw material has a vinyl content of 1% and a viscosity ...

Embodiment 2~4

[0023] Compared with Example 1, the production process of Examples 2-4 is the same and will not be repeated. The proportioning, reaction time and temperature of each component in each embodiment are shown in Table 1 below.

[0024] Table 1 Example 2-4 Material Proportion (parts by weight)

[0025]

vinyl oil

white carbon

black

silicon gel

glue

Hydroxy silicon

Oil

Methyl B

alkenyl silicon

rubber

liquid

paraffin

degree / ℃

Reaction time

/ h

Example 2

30

20

10

1

14

25

150

1.5

Example 3

50

8

20

0.6

6.4

15

150

2

Example 4

25

4

15

2

24

30

150

2

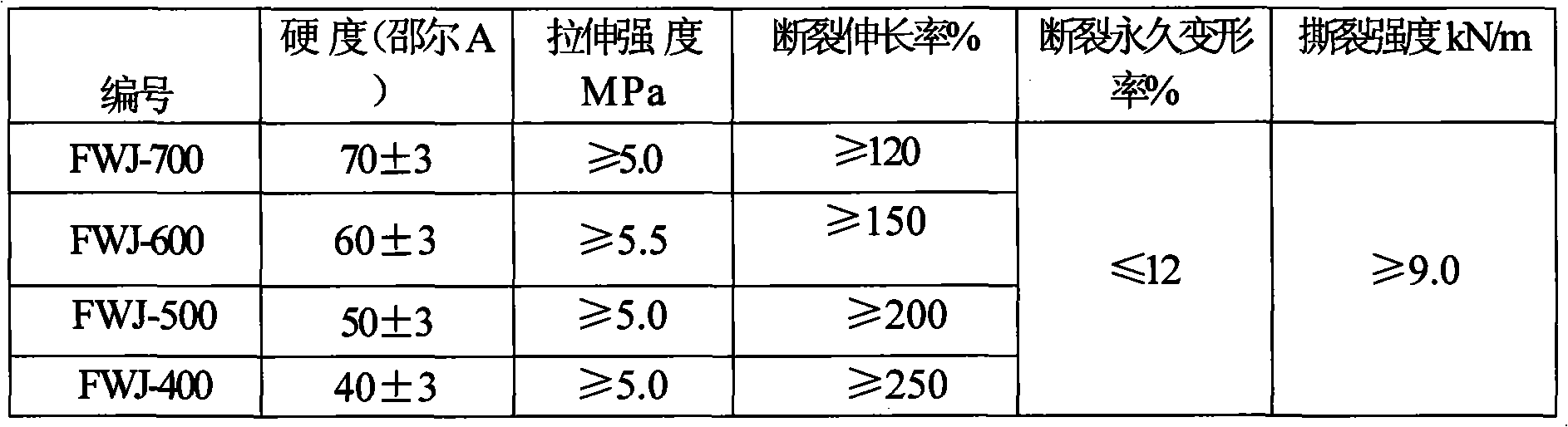

[0026] Table 2 Example 2-4 Material Proportion (parts by weight)

[0027]

Example 2

Example 3

Example 4

platinum cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com