In-line arrangement four-cylinder diesel engine balance mechanism

A technology of balance mechanism and diesel engine, which is applied to the lubrication of valve accessories, compensation of inertial force, pressure lubrication of lubricating pumps, etc. It can solve problems such as gear meshing resonance, gear fatigue damage, and large meshing gap, etc., to reduce working noise, Long service life and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

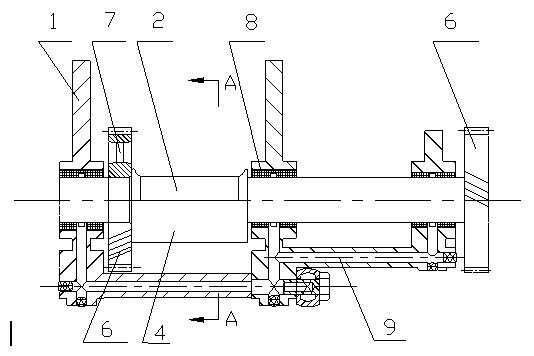

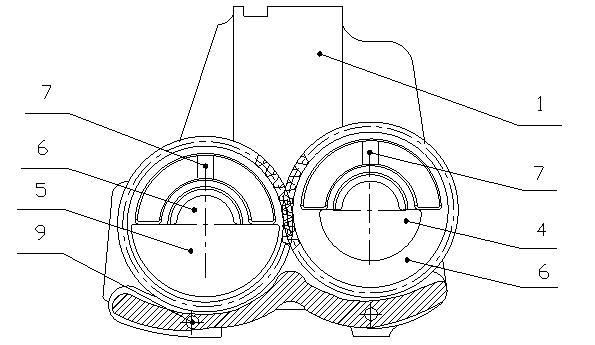

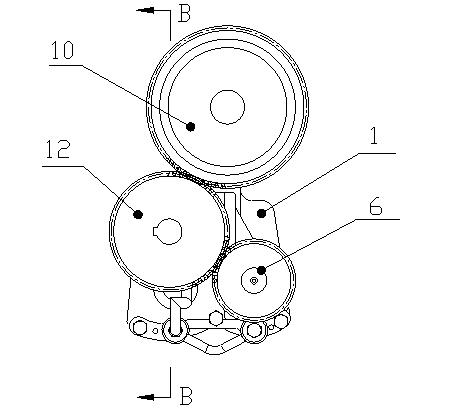

[0025] Figure 1-4 Among them, the in-line four-cylinder diesel engine balance mechanism includes the balance mechanism housing 1 and the two balance shafts installed through the balance mechanism sliding bearing 8, that is, the first balance shaft 2 and the second balance shaft balance shaft 3, the first balance shaft 2 and the second balance shaft The balance shaft 3 is evenly provided with the first balance shaft balance weight 4 and the second balance shaft balance weight 5 respectively, and the center of gravity of the two balance weights is vertically downward; the first balance shaft 2 and the second balance shaft Balance shaft gears 6 that mesh with each other are respectively installed on the balance shaft 3 .

[0026] The mass-diameter products of the two balance weights are not equal, and the diameter of the balance weight with a larger mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com