Accelerated test method for simulating non-uniform corrosion of steel bar in reinforced concrete by external electrode

An accelerated test, external electrode technology, applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as gaps, inability to truly reflect the performance of reinforced concrete components, and lack of simulation cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

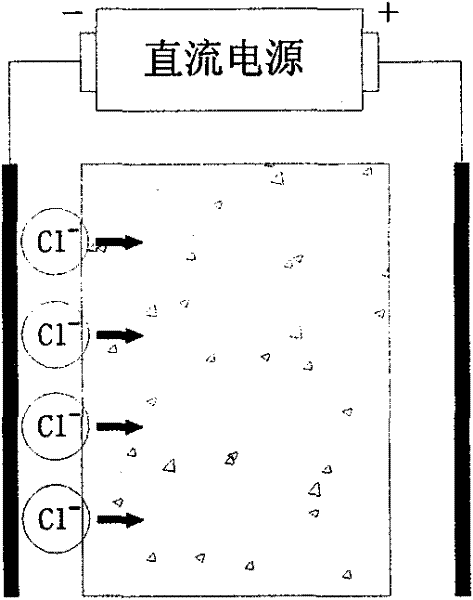

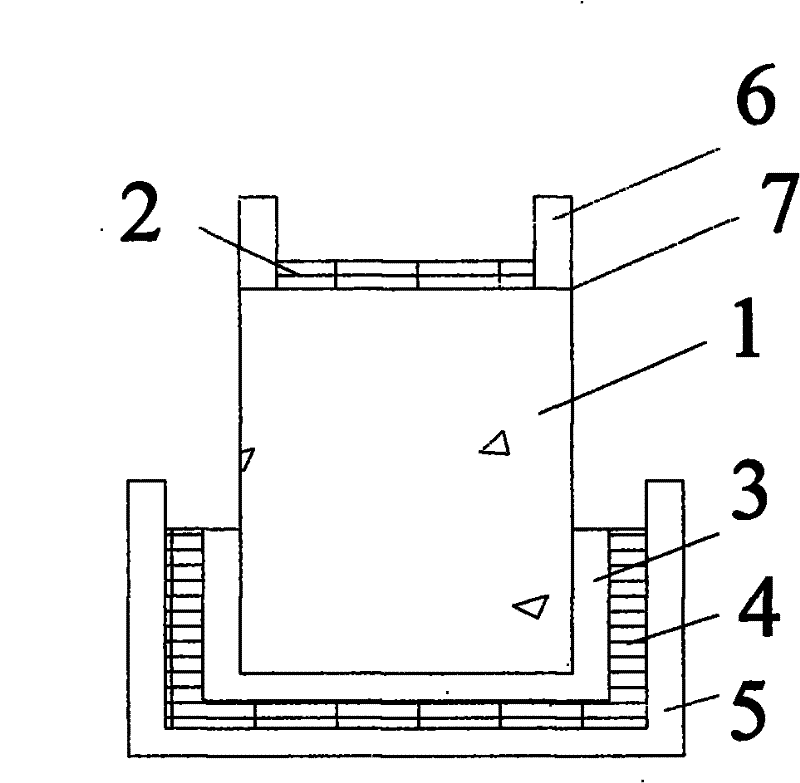

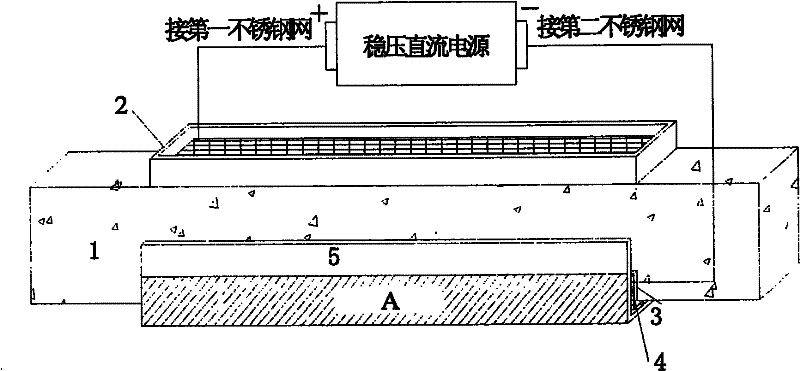

[0061] Simulate the non-uniform corrosion state of concrete in a marine environment.

[0062] (1) Preprocessing:

[0063] The size of the concrete specimen (curved beam) is 150×200×1500mm. The tensile longitudinal reinforcement is 2 deformed steel bars with a diameter of 16mm. The vertical steel bars are two smooth round steel bars with a diameter of 10mm. A water tank 6 with a length of 1000 mm and a width of 150 mm is arranged on the surface of the concrete beam on the side of the concrete specimen 1 away from the bottom of the beam to be corroded longitudinal reinforcement. The surrounding area of the water tank and the concrete surface are sealed with epoxy resin 7. The first stainless steel mesh 2 of the same size.

[0064] (2) Electroosmotic treatment:

[0065] Net protective layer thickness x d is 0.03m; the concrete connected porosity φ is 10%; the gas constant R is 8.3145J / mol / K; the average value T of the initial and final temperature of the electroosmotic trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com