Ultraviolet-curable composition for light-transmitting layer and optical disk

An ultraviolet and light transmission technology, applied in coatings, optical record carriers, optical record carrier manufacturing, etc., can solve the problems of large film warpage, difficult to apply light transmission layer, etc., achieve less scratches, excellent wear resistance , the effect of less deterioration of signal characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0140] Hereinafter, as specific examples of the optical disc of the present invention, examples of specific configurations of a single-layer optical disc and a dual-layer optical disc are shown below.

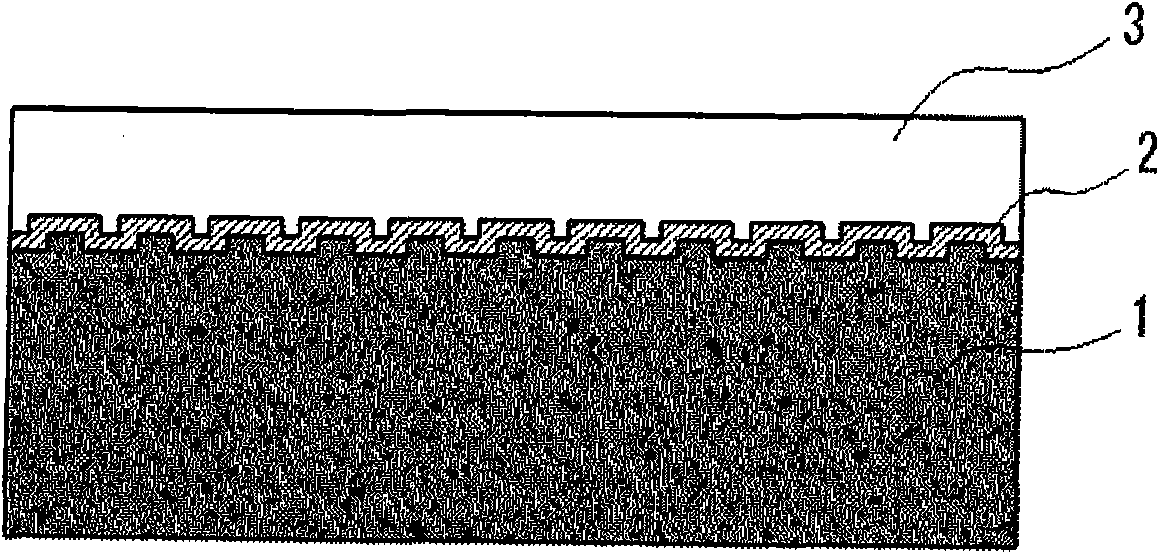

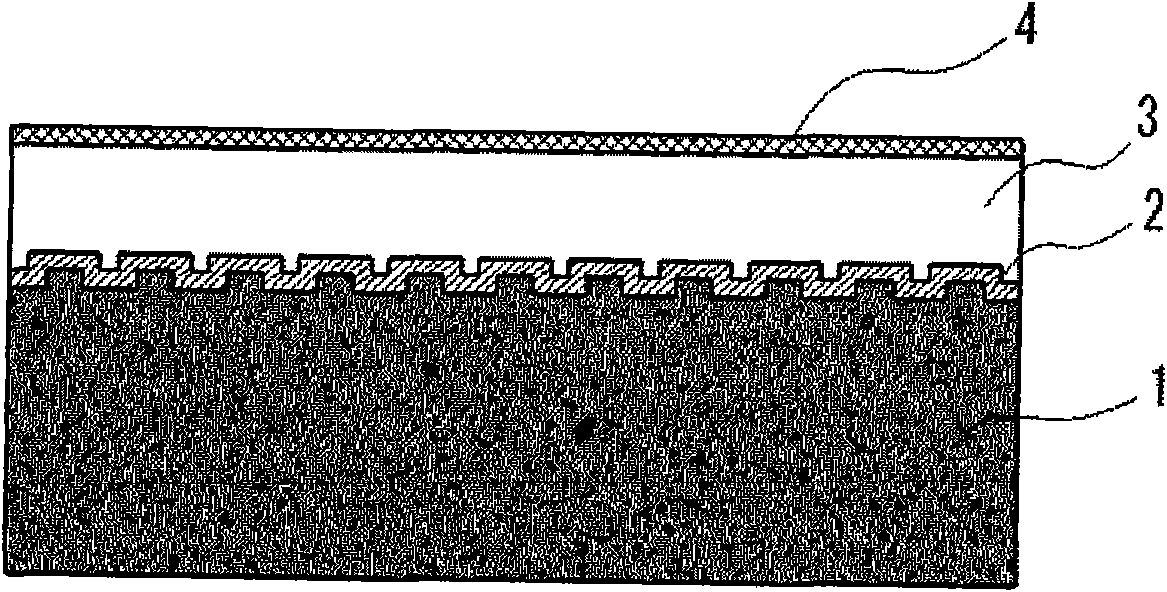

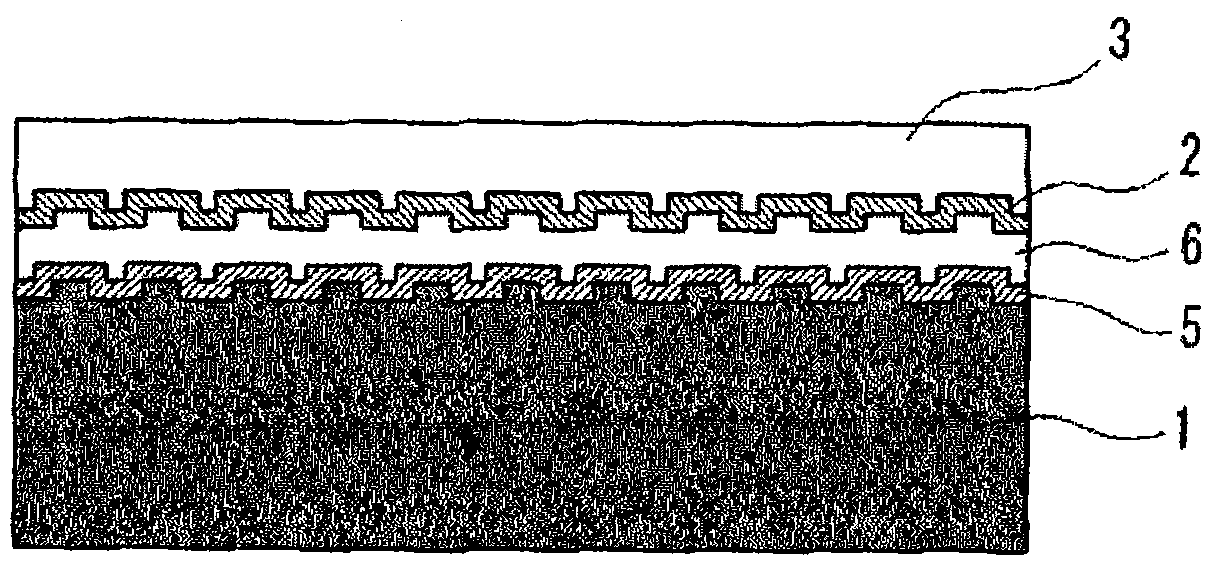

[0141] Among the optical discs of the present invention, as a preferred embodiment of a single-layer optical disc, for example, figure 1 As shown, a configuration in which a light reflection layer 2 and a light transmission layer 3 are laminated on a substrate 1 , and a blue laser beam is incident from the light transmission layer side to record or reproduce information can be mentioned. Concavity and convexity in the figure schematically represent a recording track (groove). The light-transmitting layer 3 is a layer composed of a cured product of the ultraviolet curable composition of the present invention, and has a thickness in the range of 100±10 μm. The thickness of the substrate 1 is about 1.1 mm, and the light reflection film is a thin film such as silver.

[0142] ...

Embodiment

[0151] Next, although a synthesis example and an Example are given and this invention is demonstrated in detail, this invention is not limited to these Examples. "Parts" in the following examples means "parts by mass".

[0152] Each composition formulated according to the compositions shown in the following Tables 1 to 2 (the numerical values of the compositions in the tables represent parts by mass) was heated at 60° C. for 3 hours and dissolved to prepare the compositions of Examples 1 to 9 and Comparative Examples 1 to 5. The ultraviolet curable composition of each Example and a comparative example. The following evaluation was performed about the obtained composition, and the obtained result is shown in Tables 1-2.

[0153]

[0154] The viscosity at 25° C. was measured for the ultraviolet curable composition using a B-type viscometer (manufactured by Tokyo Keiki Co., Ltd., BM type).

[0155]

[0156] Regarding the ultraviolet curable composition, the transparency o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com