Driving method of automatic level adjusting device of hydraulically operated terminal pad

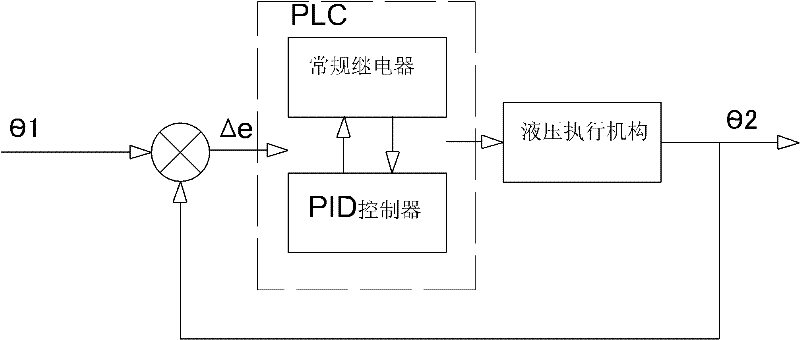

A technology of level adjustment device and driving method, which is applied in the direction of transportation and packaging, conveyor objects, etc., which can solve the problems of instability, back and forth oscillation of the connection plate, etc., and achieve the effects of short adjustment time, small overshoot and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

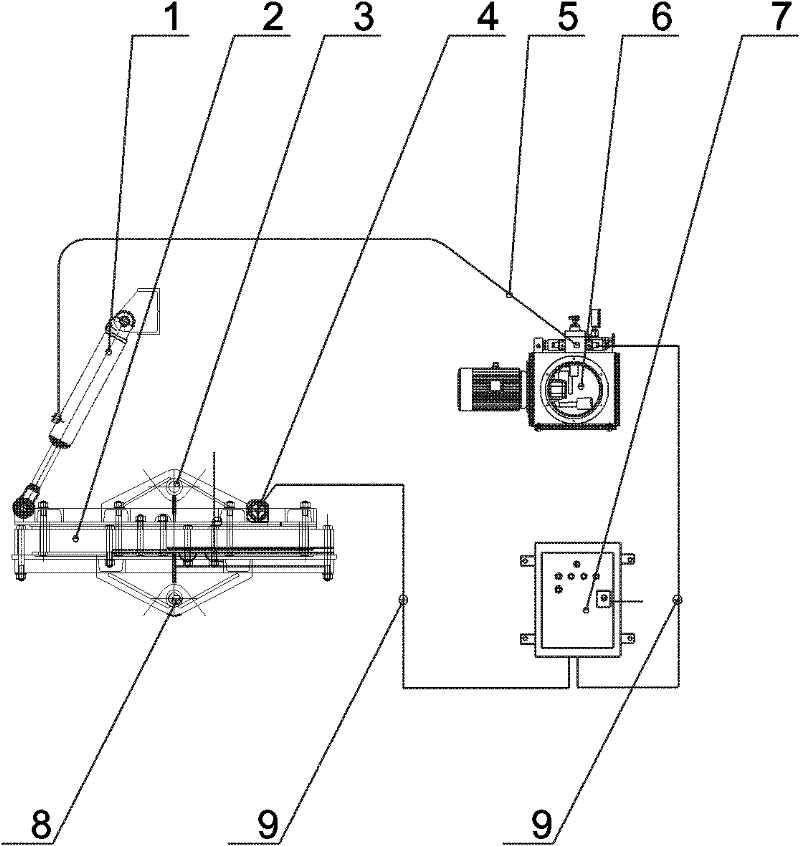

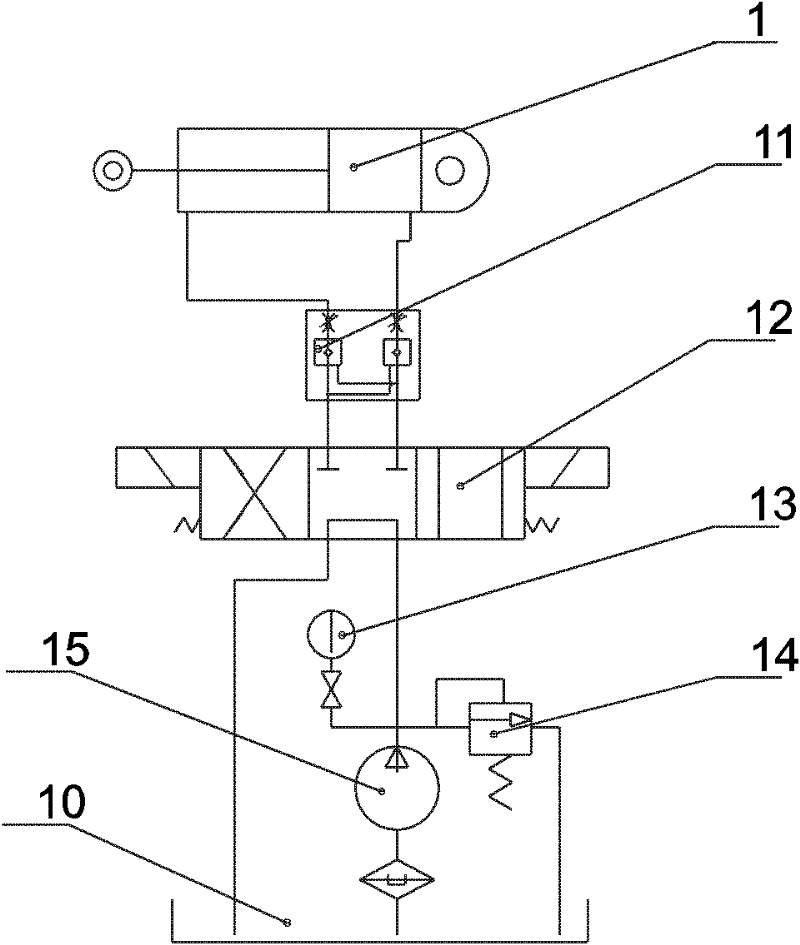

[0027] Such as figure 1 , figure 2 Among them, a hydraulically driven connection plate automatic level adjustment device, including a connection plate 2, the connection plate 2 is provided with an upper hinge point 3 of the connection plate and a lower hinge point 8 of the connection plate, and the upper hinge point 3 of the connection plate is connected to a belt conveyor, Another belt conveyor connected to the hinge point 8 under the connection plate, the connection plate 2 can rotate around the pin shaft of the hinge point 3 on the connection plate, the preferred solution is to rotate the hinge point 3 on the connection plate, one side of the connection plate 2 and the hydraulic pressure One end of the oil cylinder 1 is connected, and the other end of the hydraulic oil cylinder 1 is fixed on the belt conveyor, and the level of the connection plate 2 is controlled by the expansion and contraction of the piston of the hydraulic oil cylinder 1 .

[0028] Such as Figure 4 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com