Aluminum melting method with petroleum coke as fuel and petroleum coke aluminum melting furnace

A technology of petroleum coke and aluminum melting furnace, which is applied in the field of aluminum melting to achieve full combustion, which is conducive to full combustion and reduces costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

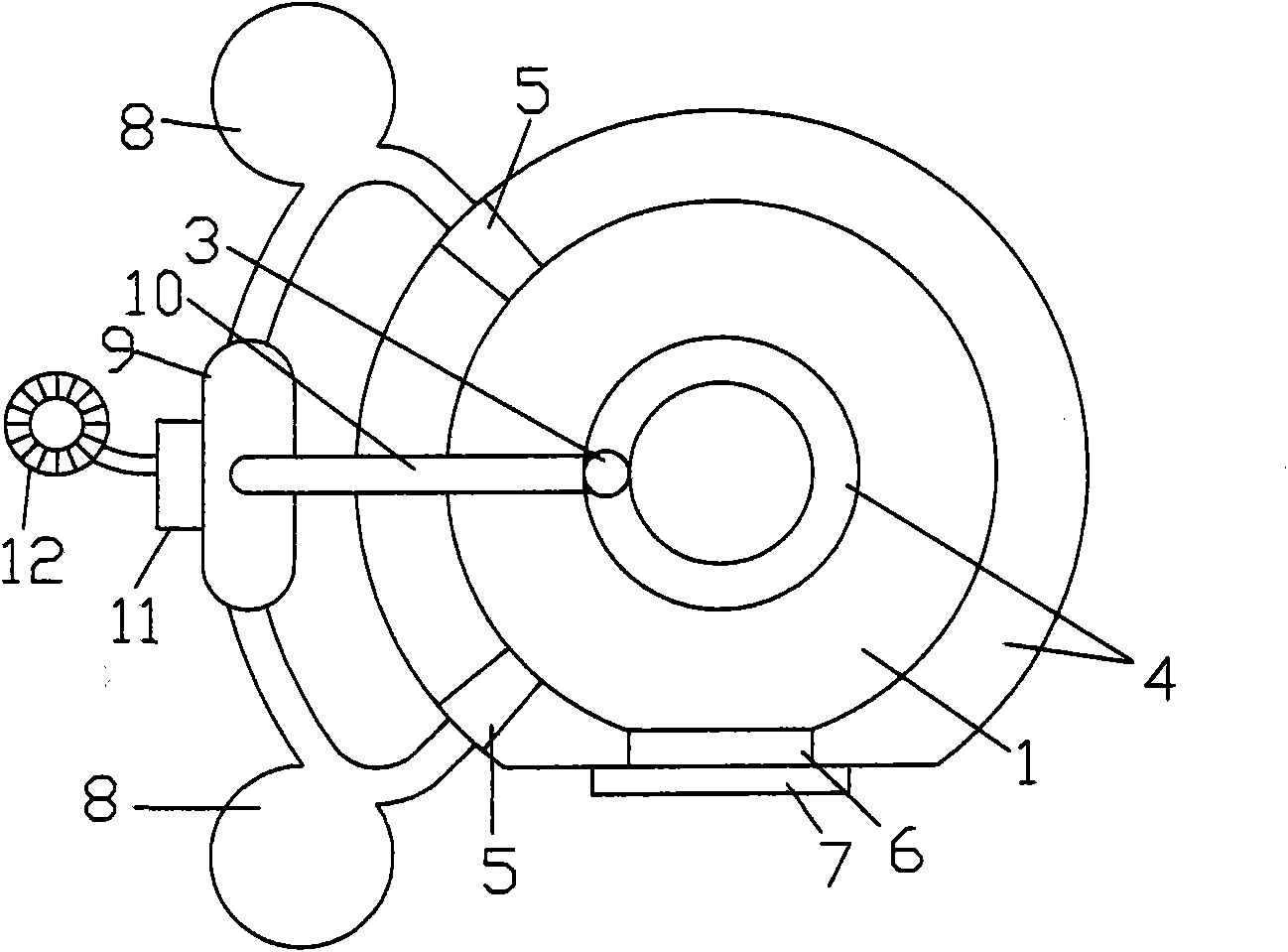

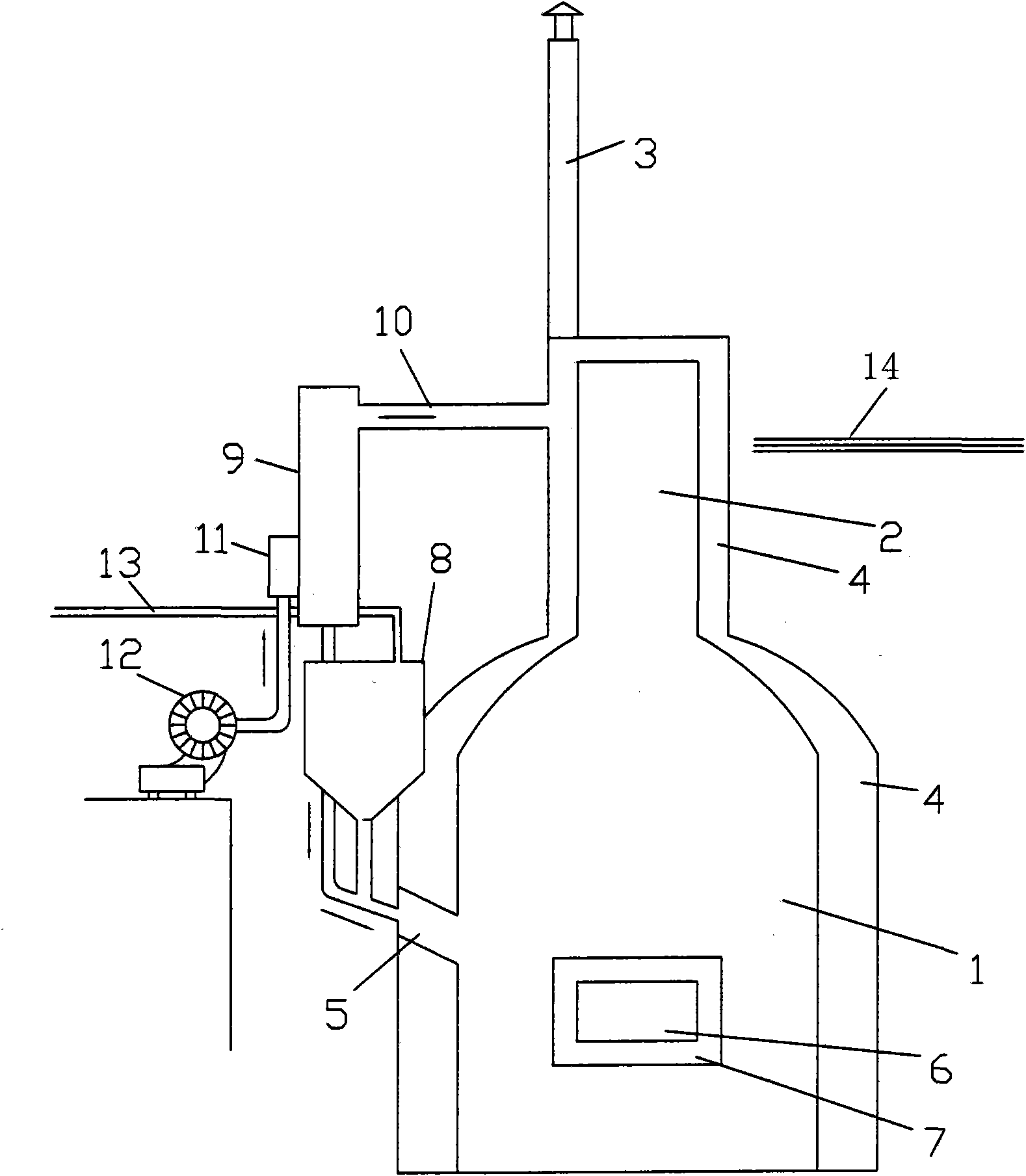

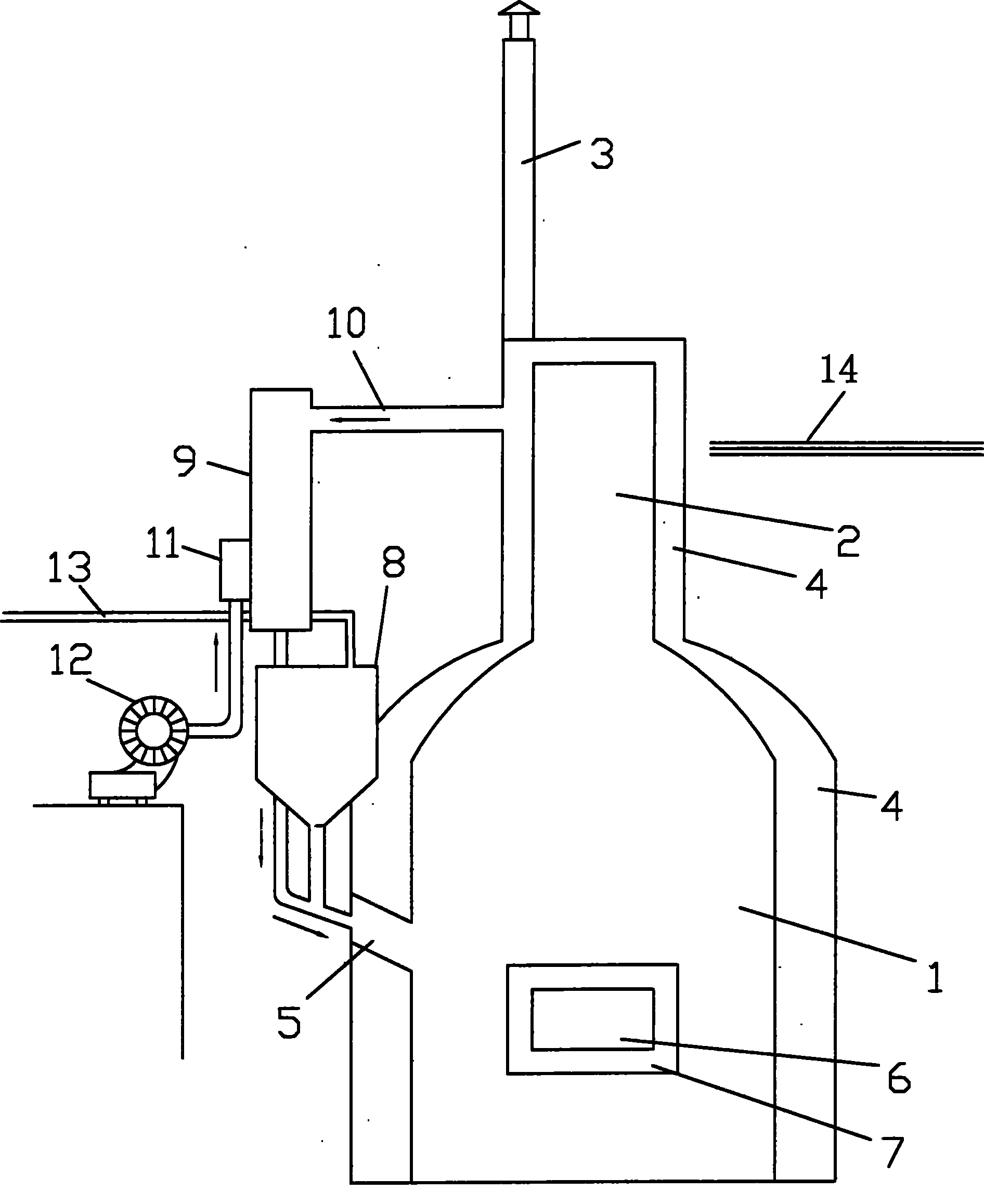

[0029] Hereinafter, specific embodiments of the present invention will be described in conjunction with the accompanying drawings.

[0030] The present invention uses petroleum coke as the method for fuel melting aluminum comprising:

[0031] Use powdered petroleum coke, that is, petroleum coke powder, as fuel, and the particle size of petroleum coke powder is to pass through a 200-300 mesh sieve;

[0032] The petroleum coke powder is atomized under the aerodynamic action of the hot air flow, and is sprayed into the main body of the furnace together with the hot air flow, and burns in the main body of the furnace, so that the temperature of the main body of the furnace rises, and the feeding channel from the upper part of the main body of the furnace Added aluminum melts;

[0033] Petroleum coke powder is sprayed into the main body of the furnace to burn to form a combustion flame. The petroleum coke powder particles are wrapped by high-temperature combustion-supporting air, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com