Comprehensive control method for alternating-current electric pump

A comprehensive control and electric pump technology, applied in the direction of pump control, machine/engine, liquid variable capacity machinery, etc., can solve the problems of small available power, long duration, easy overheating and burning, etc. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below through specific examples.

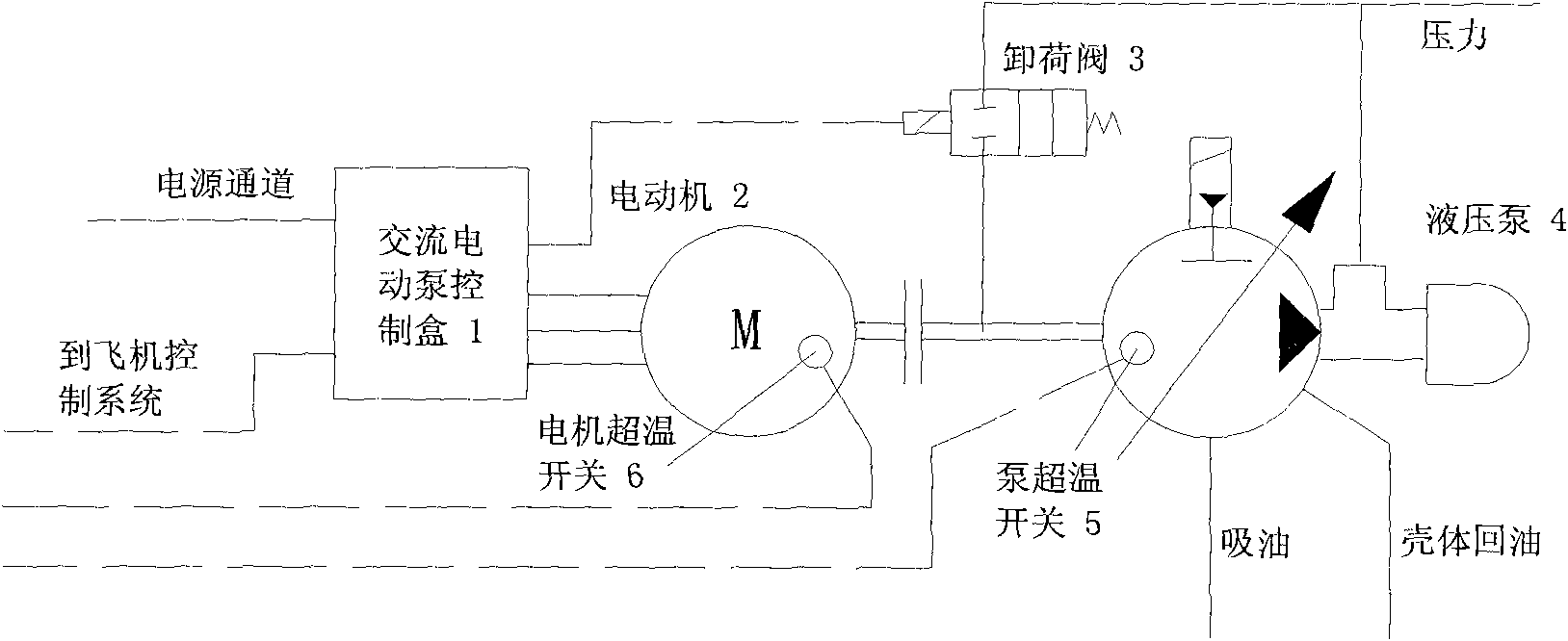

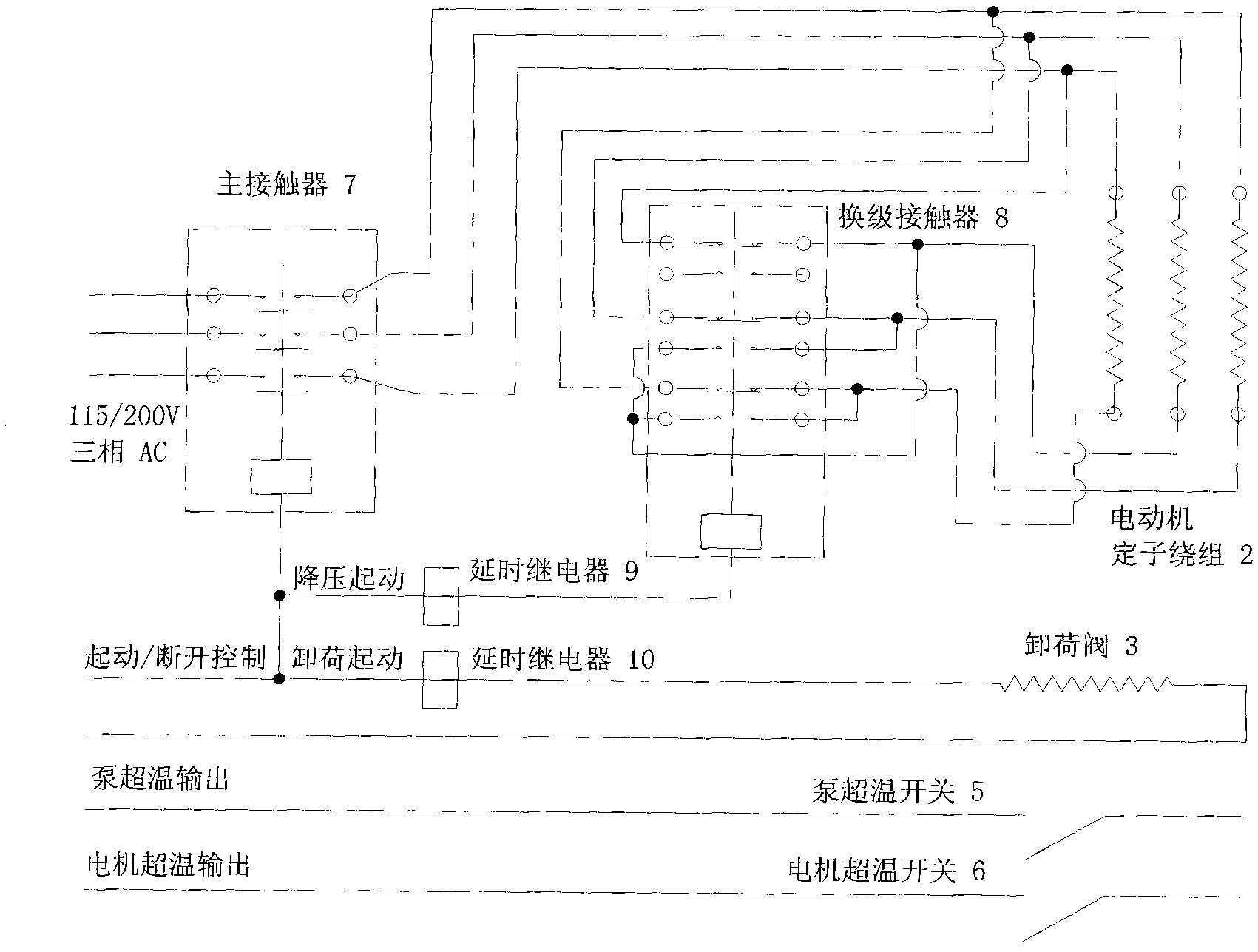

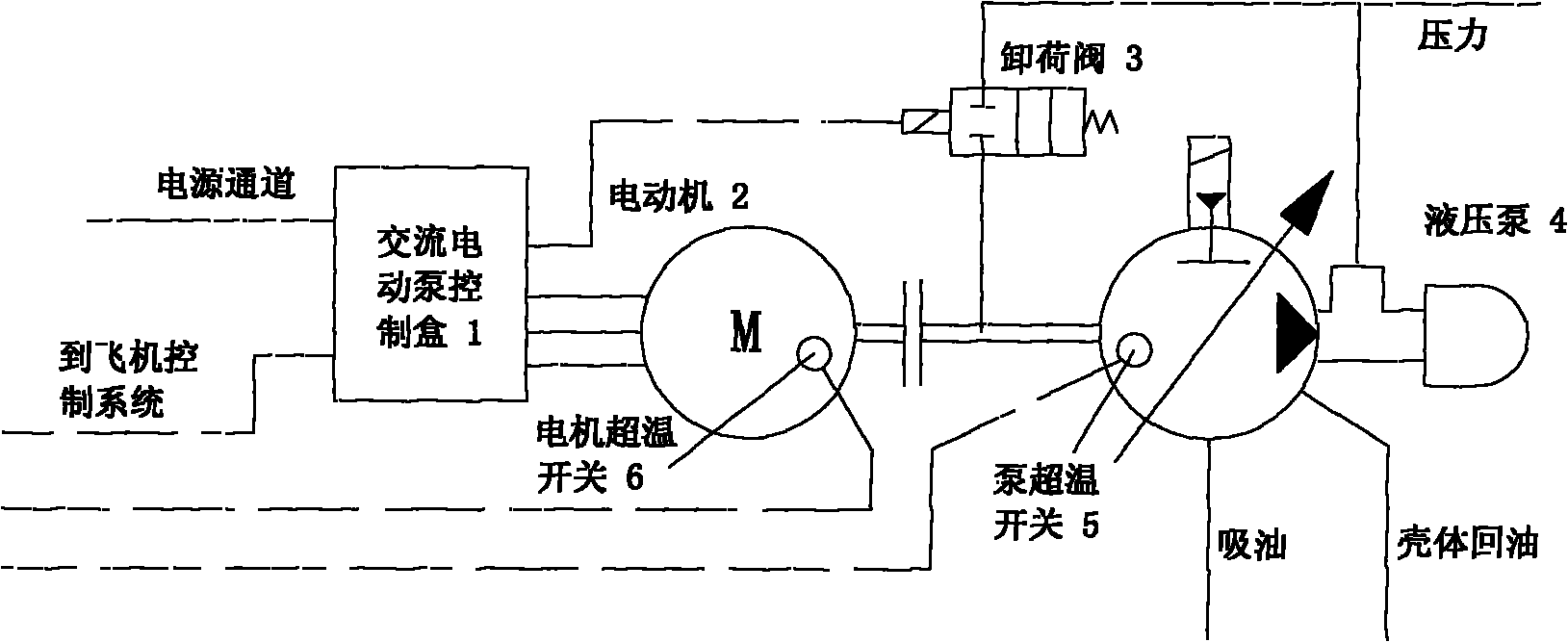

[0016] A hydraulic pump assembly driven by an 18kW motor is controlled as follows: reduce the starting impulse current by switching stages, shorten the starting time and increase the probability of successful starting by unloading starting, and realize fault self-detection by over-temperature detection.

[0017] When starting, the control signal (5V DC) enters the control box of the AC electric pump to drive the main contactor, so that the induction motor in the AC electric pump is connected to the power supply; at the same time, the control signal passes through a 1.5s delay relay to drive the step-change contactor, The three-phase coil of the induction motor is connected to the power supply in a star connection, and the induction motor starts to rotate.

[0018] At the same time, the control signal drives the unloading valve on the hydraulic pump through a 1.5s delay relay to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com