Low-pressure drop, fully uniform-flow distributor for air source heat pumps

An air source heat pump and liquid separator technology, which is applied in refrigeration and liquefaction, fluid circulation arrangement, lighting and heating equipment, etc., can solve the problems of high cost, complicated manufacturing process, and large volume, and achieve uniform distribution and improve mixing Speed and uniformity, evenly mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

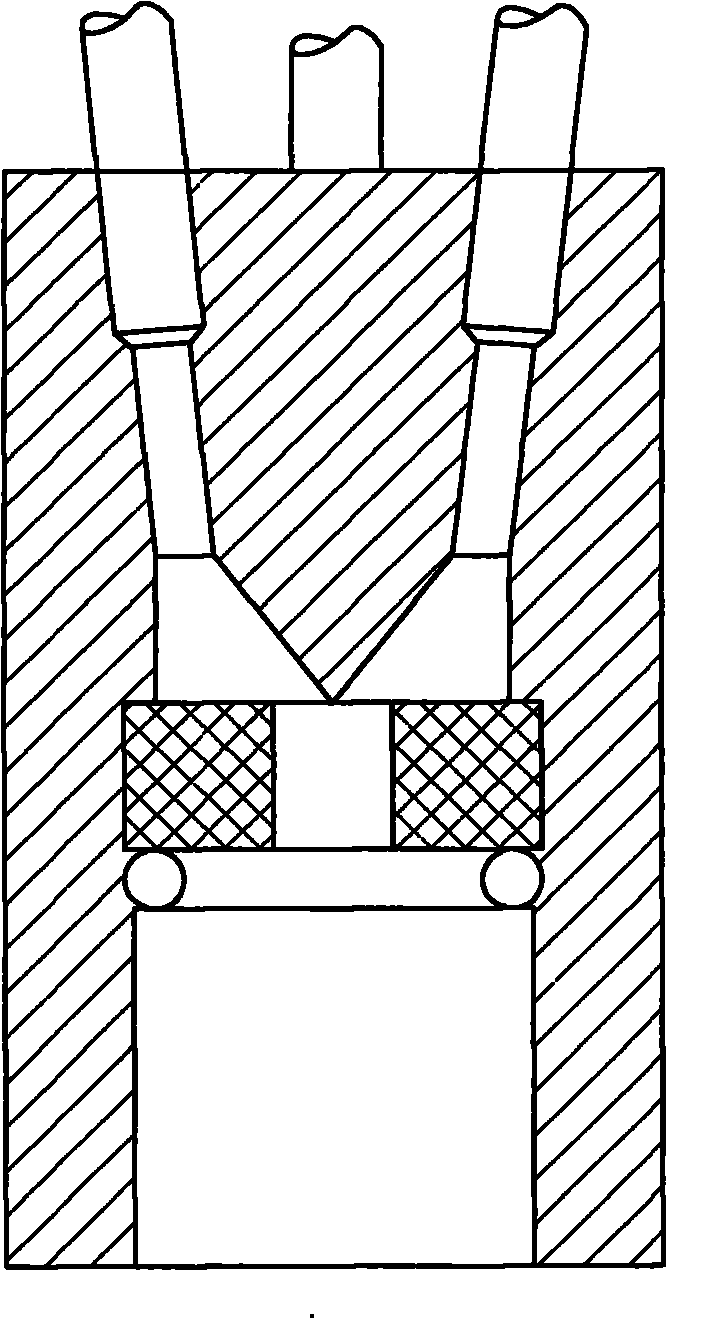

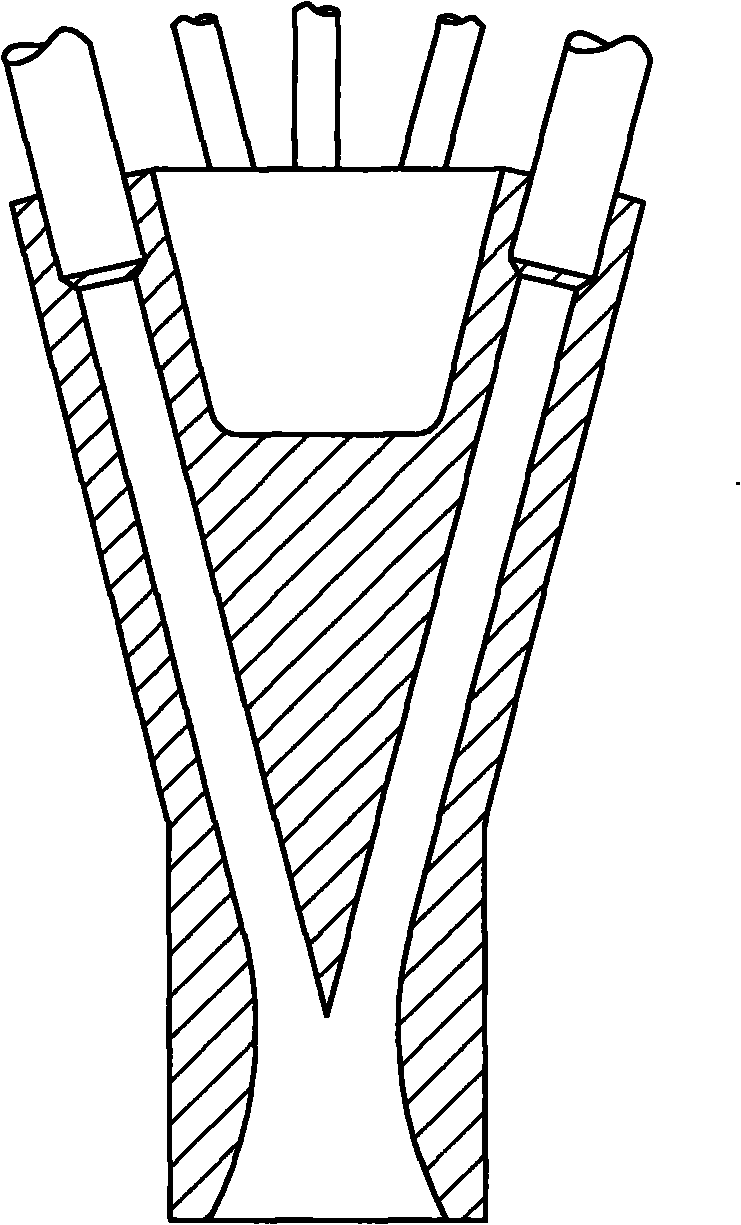

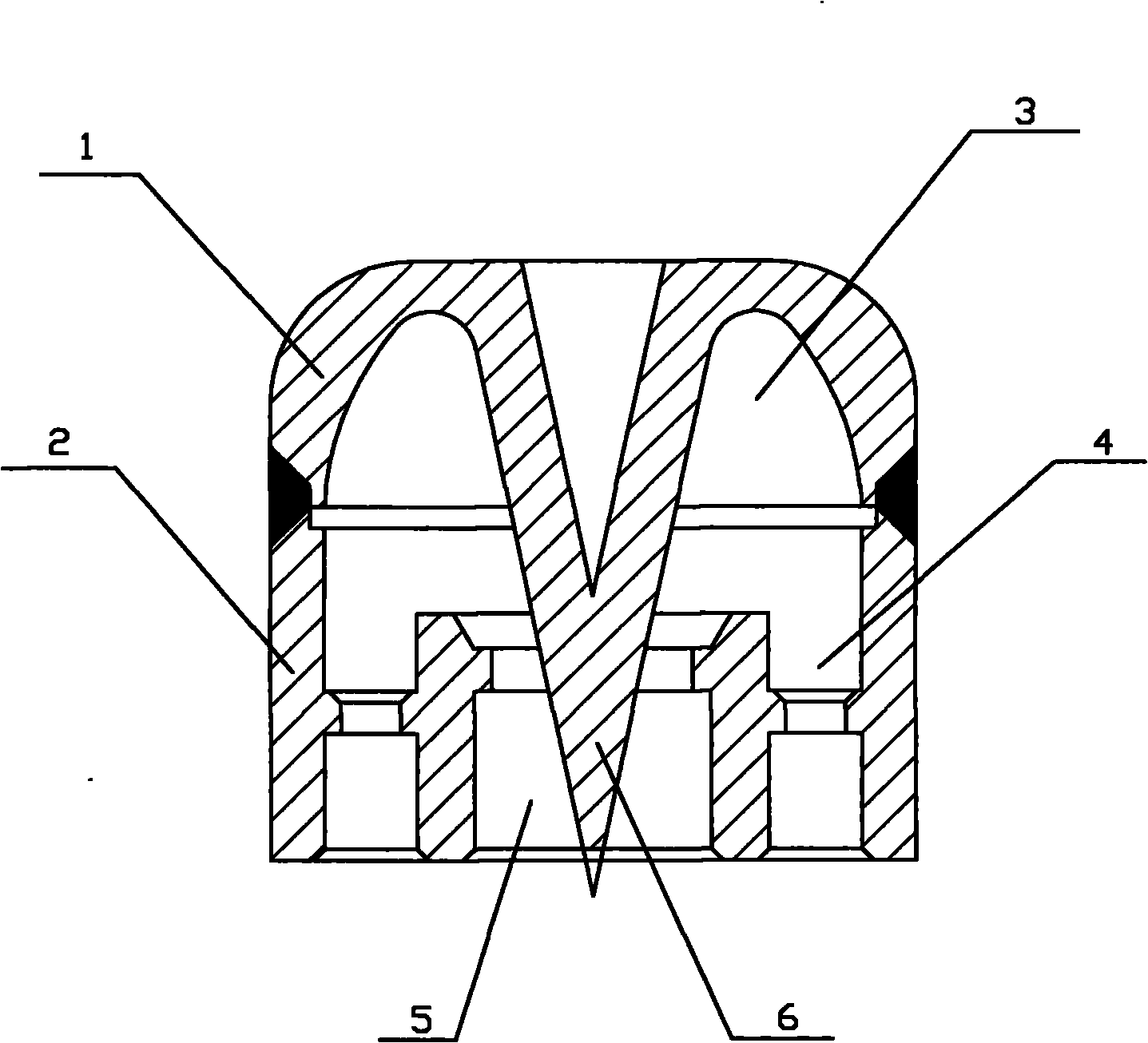

[0014] Such as image 3 , Figure 4 with Figure 5 As shown, the present invention includes two parts, the liquid dispenser top cover 1 and the liquid dispenser seat 2, the liquid dispenser is assembled by sealing and welding between the liquid dispenser top cover 1 and the liquid dispenser seat 2, and the space between the two is The cavity forms a vapor and liquid two-phase mixing chamber 3, and the liquid separator seat 2 is provided with a vapor and liquid two-phase refrigerant inlet 5 and a plurality of vapor and liquid homogeneous phase distribution tanks 4, and the vapor and liquid two-phase refrigerant The inlet 5 and the vapor-liquid homogeneous distribution tank 4 are all in communication with the vapor-liquid two-phase mixing chamber 3 and are located on the same side of the liquid separator, and the vapor-liquid two-phase refrigerant inlet 5 is located at the separator At the central part of the end face of the liquid container seat 2, the vapor-liquid homogeneou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com