Outer-rotor composite permanent-magnetic brushless in-wheel motor of electric vehicle

A permanent magnet brushless, in-wheel motor technology, used in electric vehicles, motors, synchronous motors with static armatures and rotating magnets, etc., can solve problems such as mechanical wear, low power density of mechanical speed-increasing gearboxes, and noise. , to reduce the amount of permanent magnets, improve stability and comfort, and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

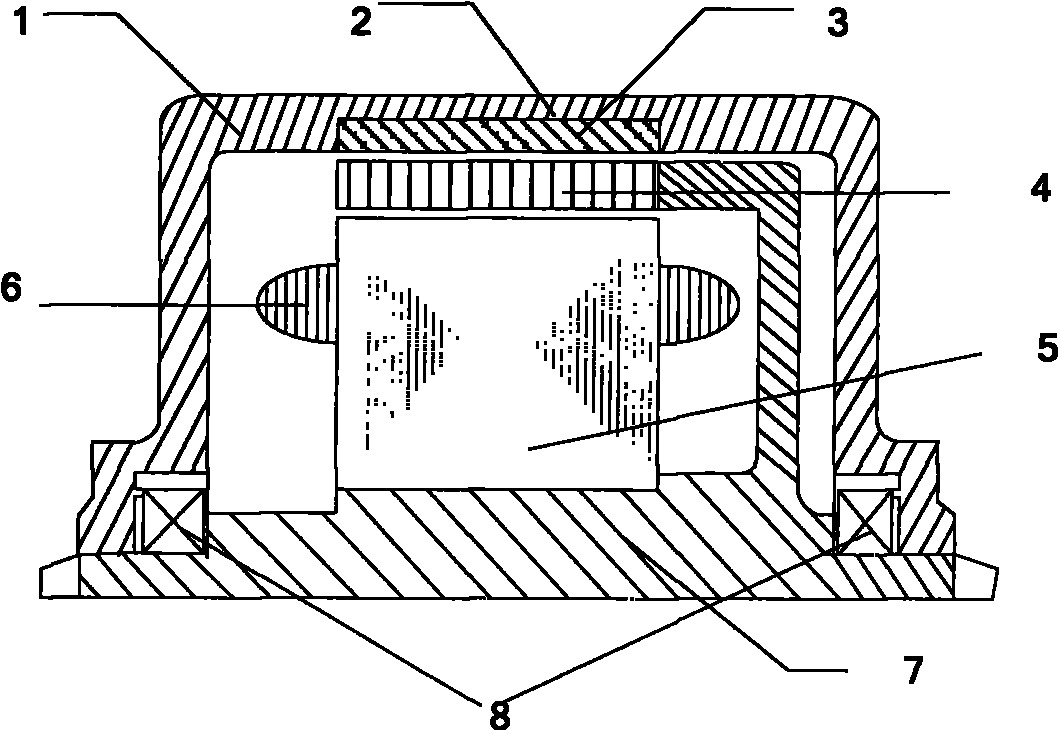

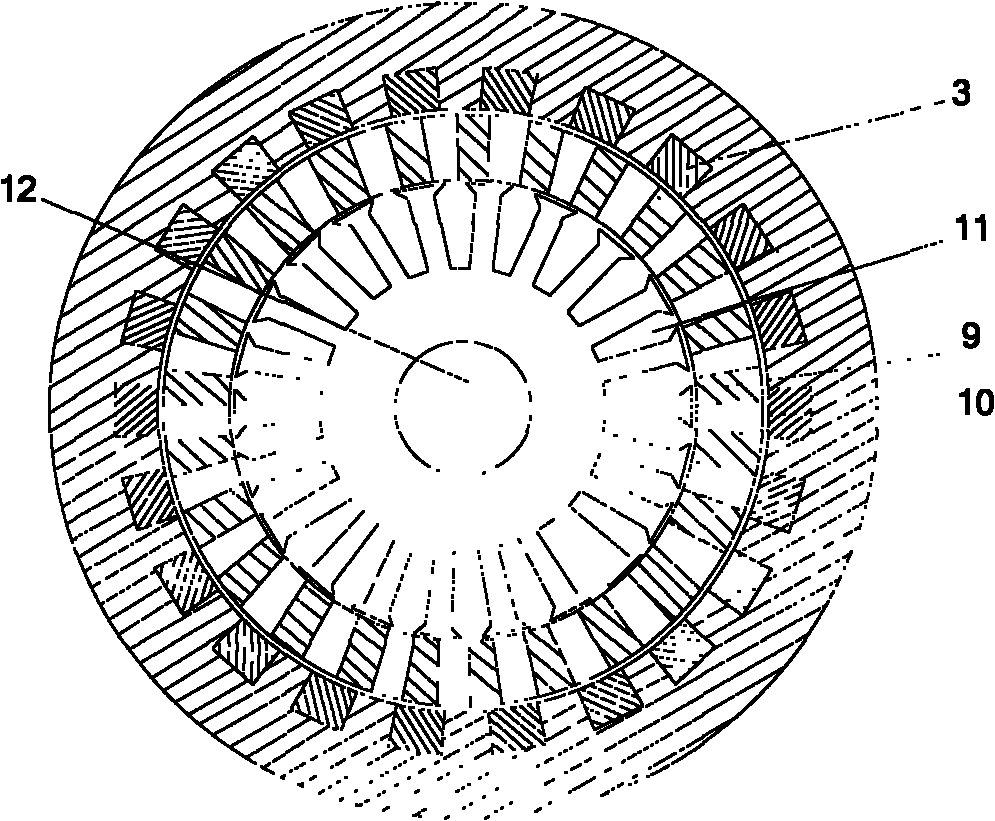

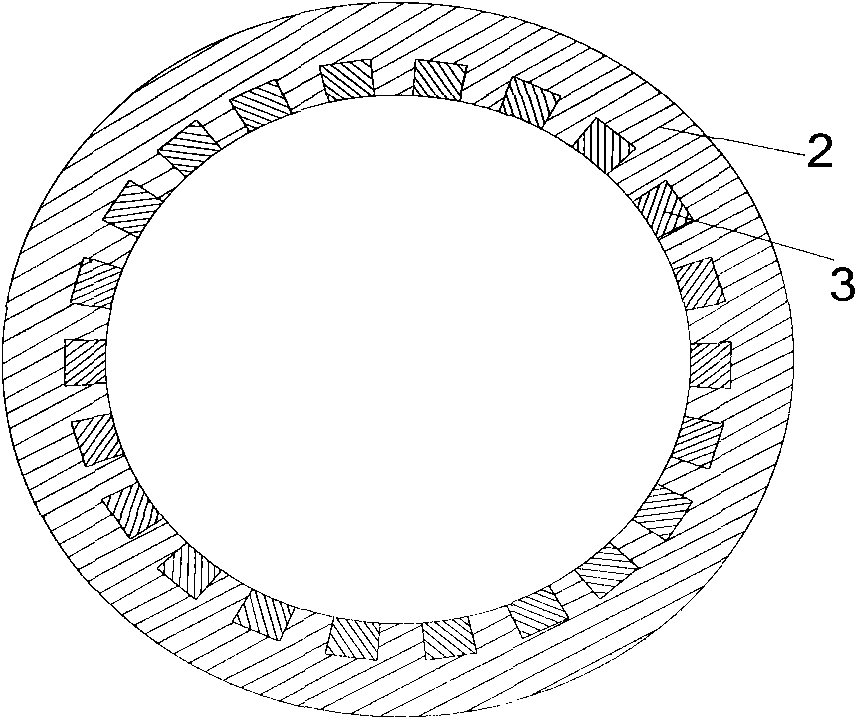

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] The purpose of this invention is to provide a new type of outer rotor composite permanent magnet brushless hub motor device for electric vehicles, which solves the problems of low power density, mechanical wear and noise of the mechanical speed-increasing gearbox in the existing transmission device, and at the same time solves the problems of the traditional magnetic On the basis of the gear structure, the inner rotor of a magnetic gear is omitted, which simplifies the manufacturing process of the device, reduces the volume, weight and manufacturing cost of the generator, improves the efficiency, and eliminates the large vibration and noise. When the hub motor is used in electric vehicles, the omission of the inner rotor also reduces the unsprung mass of the vehicle and improves the stability and comfort of driving. The device will solve the problem of insuffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com