Current sensor and implementing method thereof based on alloy resistor

A technology of current sensor and alloy resistance, which is applied in the direction of measuring current/voltage, instruments, and measuring electrical variables, etc. It can solve problems such as complex electromagnetic or optical conversion principles, threats to reliability and versatility, and unsatisfactory linearization to achieve suitable Large-scale promotion and use, eliminating the effects of poor environmental adaptability and easy interface handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

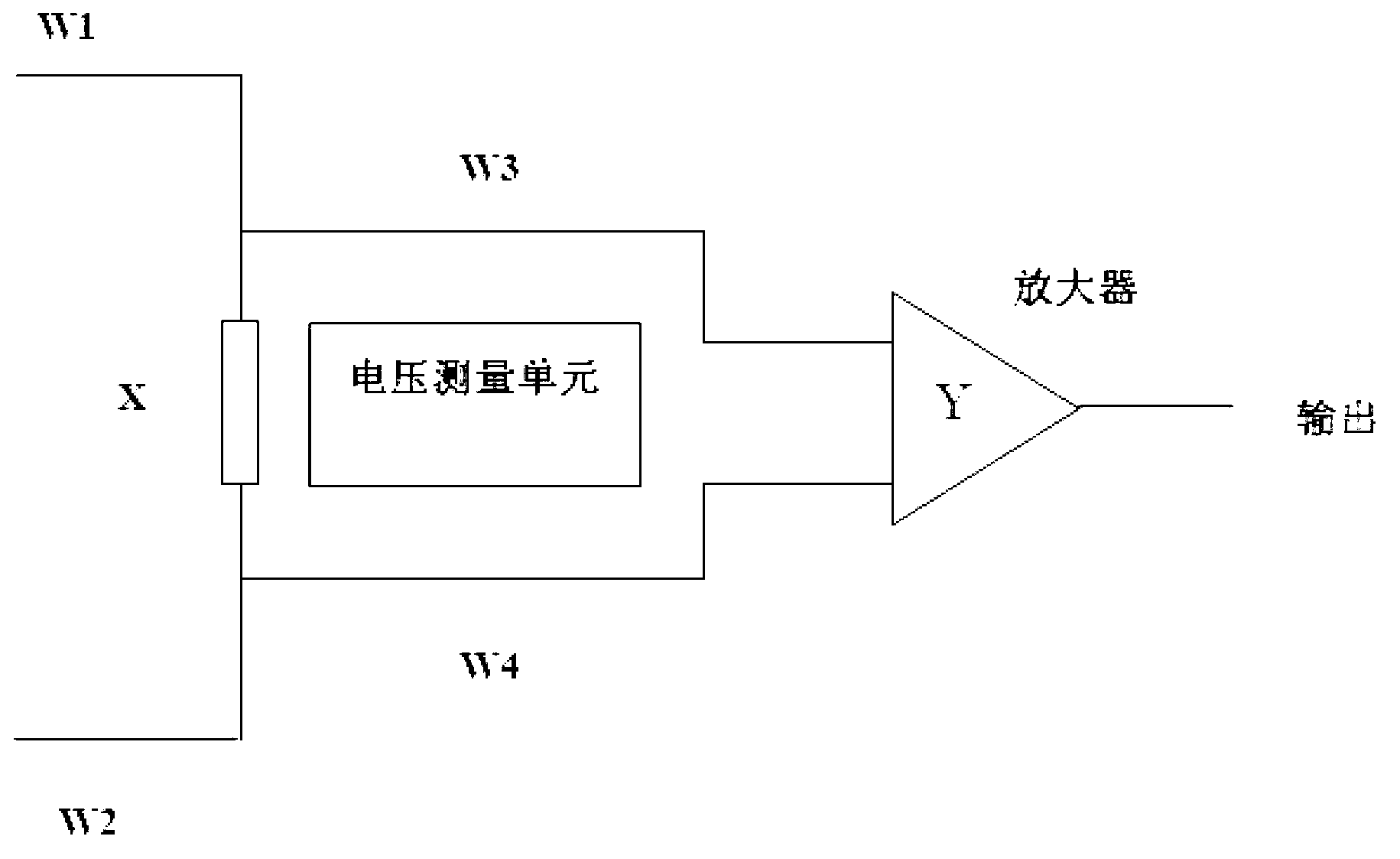

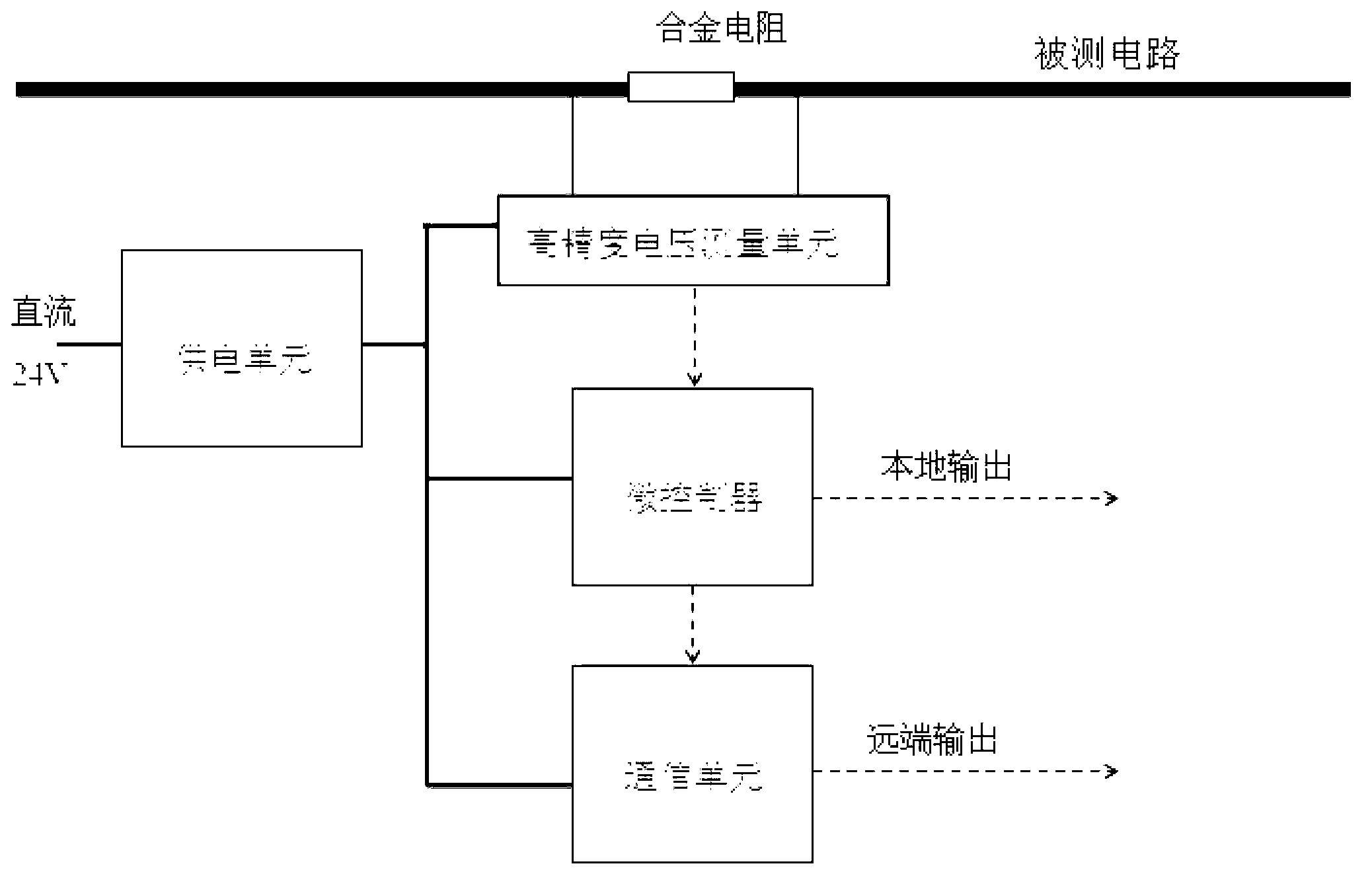

[0028] A current sensor based on an alloy resistor proposed in this embodiment includes an alloy resistor, a power supply unit, a voltage measurement unit, a controller, and a communication unit; its principle schematic diagram is as follows figure 1 As shown in the figure, W1 and W2 are directly connected to the circuit to be collected, W3 and W4 are sensing lines, X is a measuring device based on alloy resistance, and Y is a peripheral amplifier circuit.

[0029] The sensor directly connects the high-precision alloy resistance in series with the high-voltage and high-current circuit under test. The alloy resistor has a sufficiently small and stable ohm value, and the voltage drop generated by the measured strong current flowing through the resistor sheet falls within the measurement range of the weak current measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com