Engine residual heat power generation device and power generation module thereof

A waste heat power generation and engine technology, applied in the direction of generators/motors, electrical components, etc., can solve problems such as large temperature difference, exceeding the optimal temperature range, and insufficient exhaust heat, so as to improve utilization rate, improve thermoelectric conversion efficiency, reduce The effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

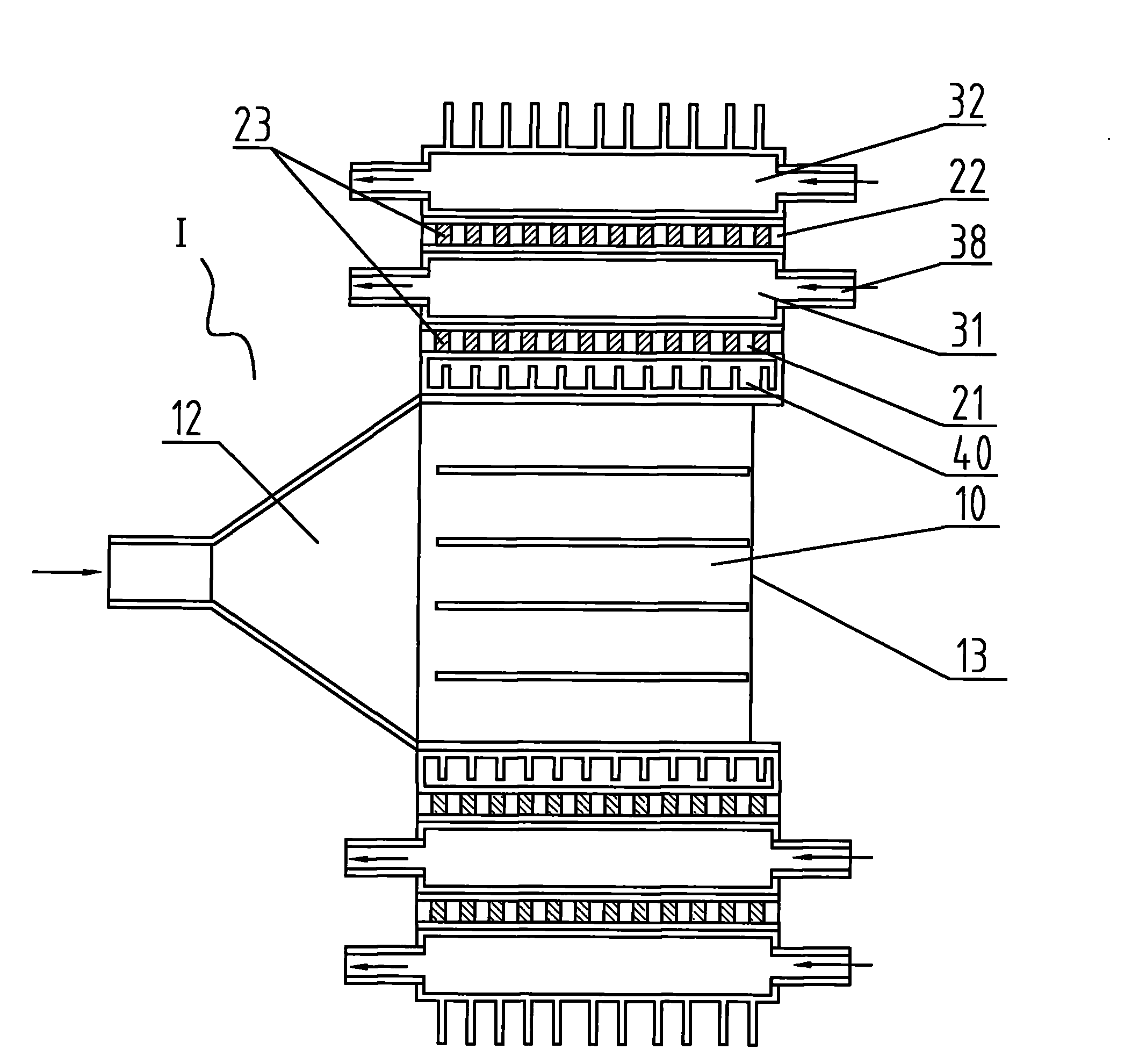

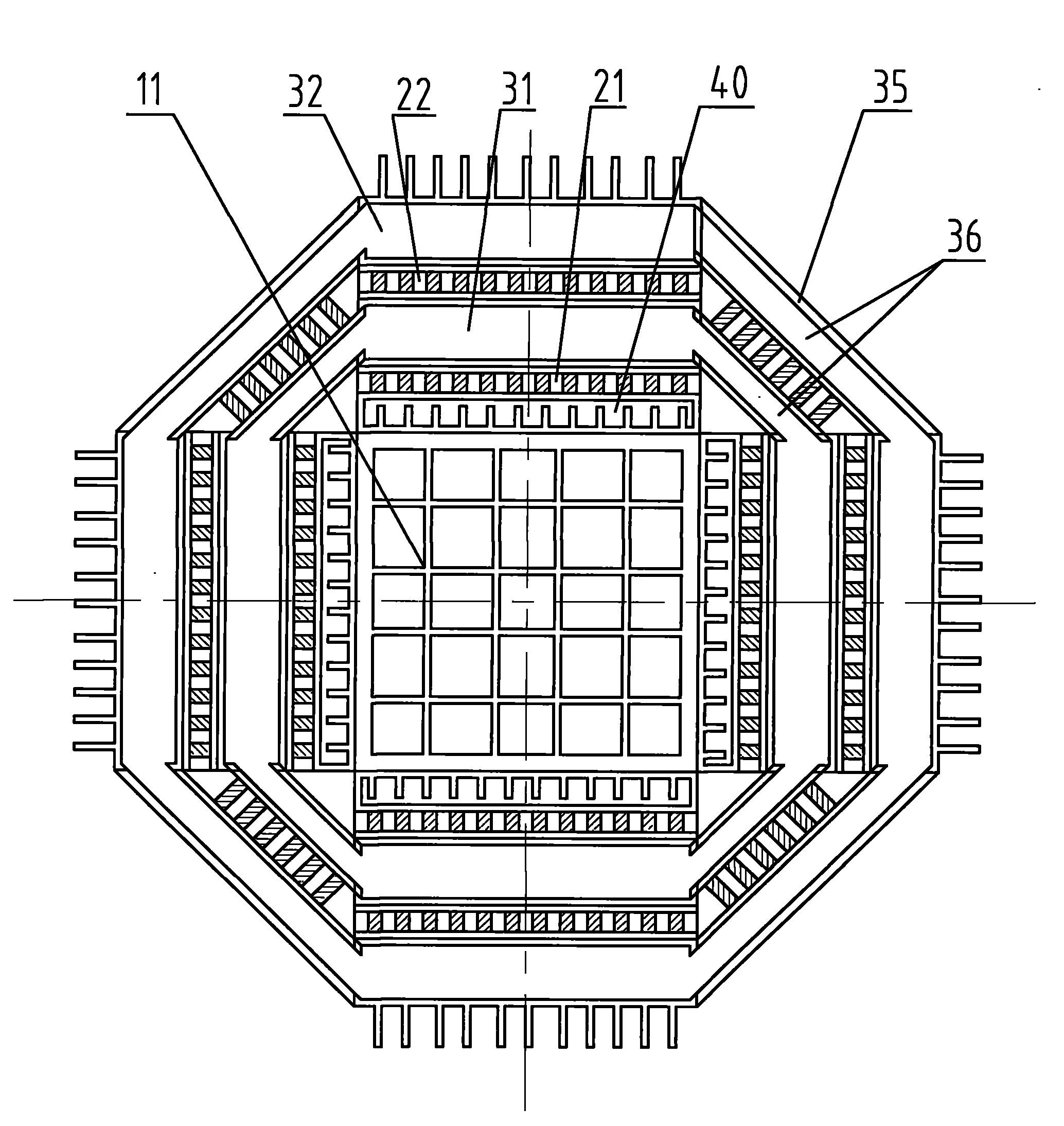

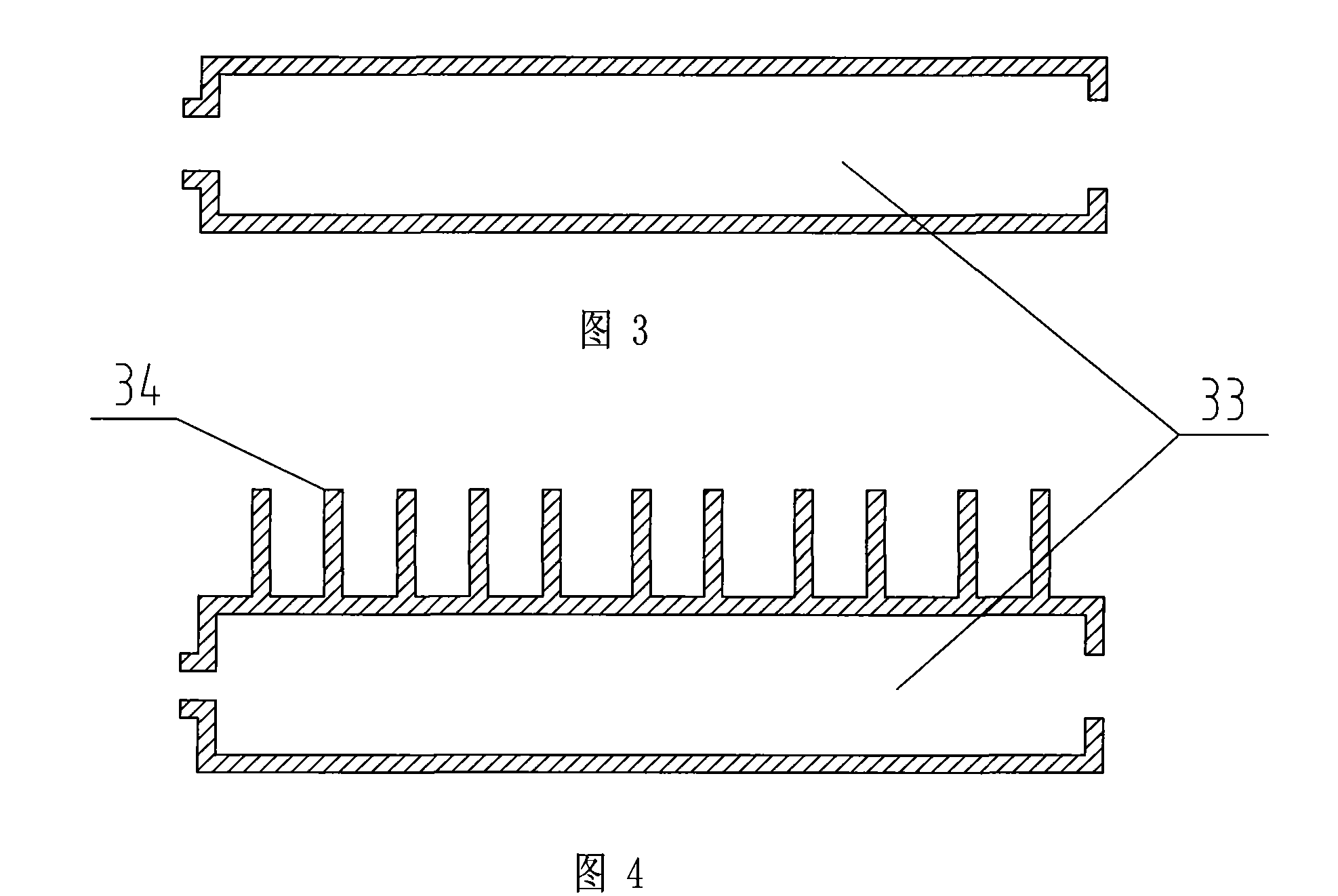

[0024] Refer to the attached Figure 1 to Figure 5 . The engine waste heat power generation module 1 of this embodiment includes a gas pipeline 10, a thermoelectric converter layer, and a cooler layer, wherein the thermoelectric converter layer includes a first thermoelectric converter layer 21 and a second thermoelectric converter layer 22, and the cooler The layers include a first cooler layer 31 and a second cooler layer 32, and an energy storage layer 40 is also provided between the gas pipes and the first thermoelectric converter layer. The first thermoelectric converter layer 21 is located between the energy storage layer and the first cooler layer 31 , and the second thermoelectric converter layer is located between the first cooler layer 31 and the second cooler layer 32 .

[0025] In order to increase the heat-absorbing area of the gas pipe wall, a grid 11 such as a grid or a rib plate can be arranged in the gas pipe 10 . The grids 11 are distributed along the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com