Die casting mould special for ultrathin-wall non-leakage aviation aluminium alloy element

A die-casting mold and aluminum alloy technology, which is applied in the field of die-casting molds for ultra-thin-walled non-leakage aviation aluminum alloy parts, can solve the problems of strict acceptance, small processing allowance, and no pressure-resistant leakage, etc., to achieve improved airtightness performance, increased exhaust velocity, and improved appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing:

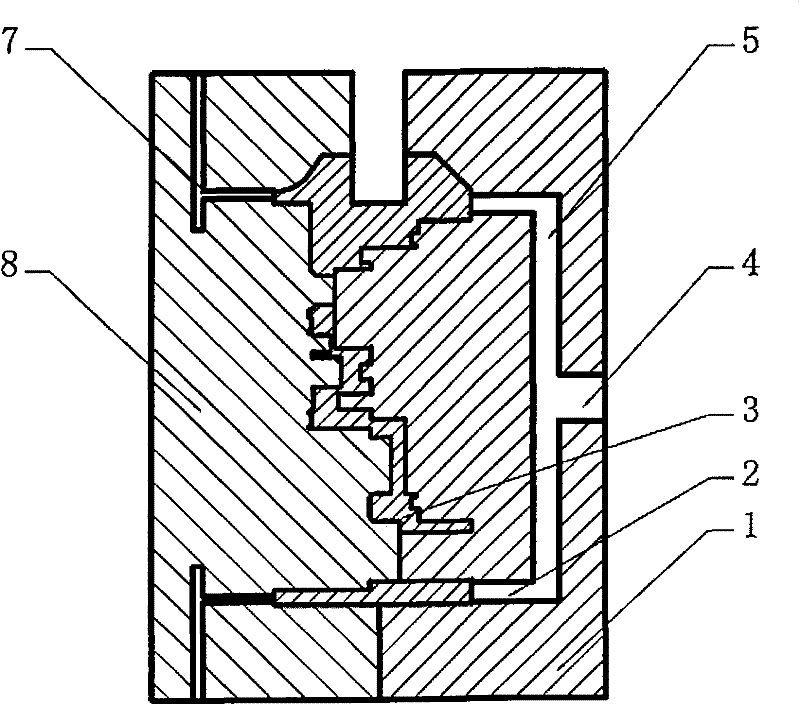

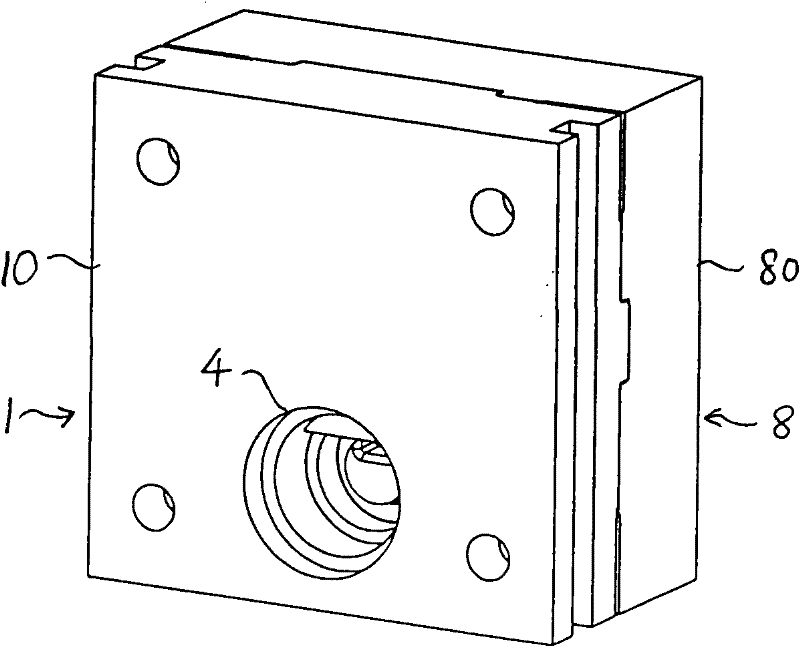

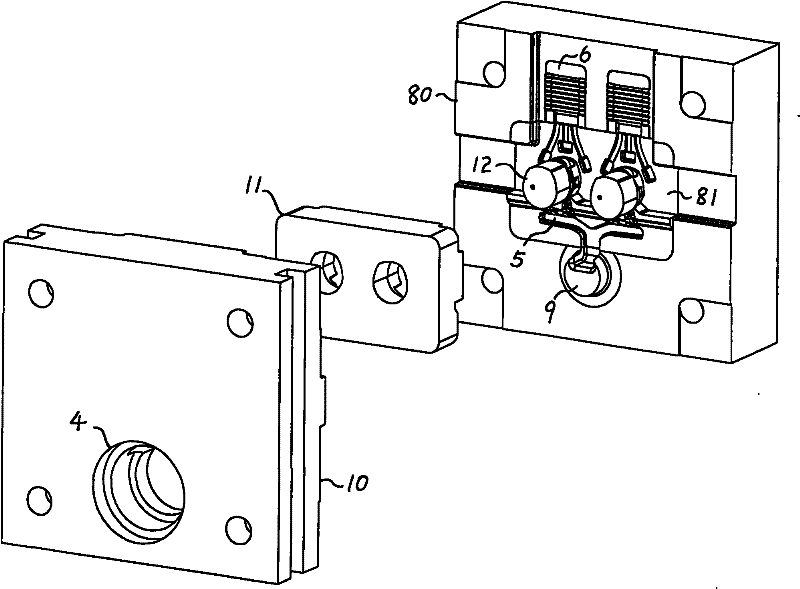

[0044] A special die-casting mold for ultra-thin wall and non-leakage aviation aluminum alloy parts, including a right mold 1, a left mold 8 and a die-casting inlet 4, characterized in that the right mold 1 is mainly composed of a fixed mold frame 10 and embedded in the fixed mold frame 10 The die-casting inlet 4 is arranged on the fixed die frame 10, the fixed die insert 11 is provided with a cavity 112, and the die cavity 112 is provided with a fixed die insert 12; the left die 8 is mainly composed of a movable mold frame 80 and a movable mold insert 81 embedded in the movable mold frame 80, the fixed mold insert 11 and the movable mold insert 81 are relatively fitted together, and the movable mold insert 81 is provided with a connecting die-casting inlet 4 The distribution runner 5 of the movable mold insert 81 is provided with a double annular inner gate 2 connecting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com