Sodium hypochlorite generator electrolyzer

A sodium hypochlorite and electrolytic cell technology, applied in electrolysis process, electrolysis components, cells, etc., can solve the problems of power consumption and large amount of water, and achieve the effects of less consumption, power saving and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

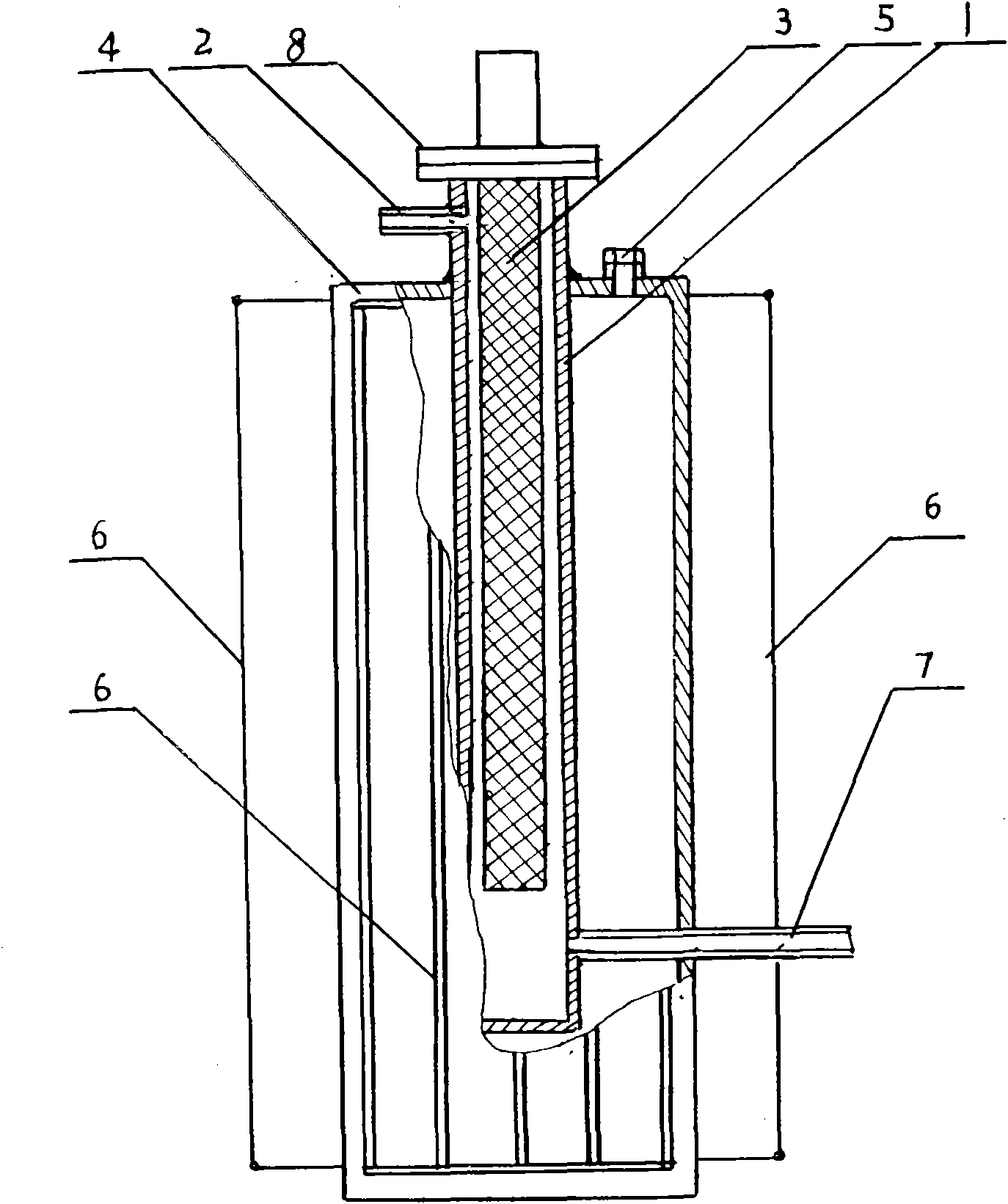

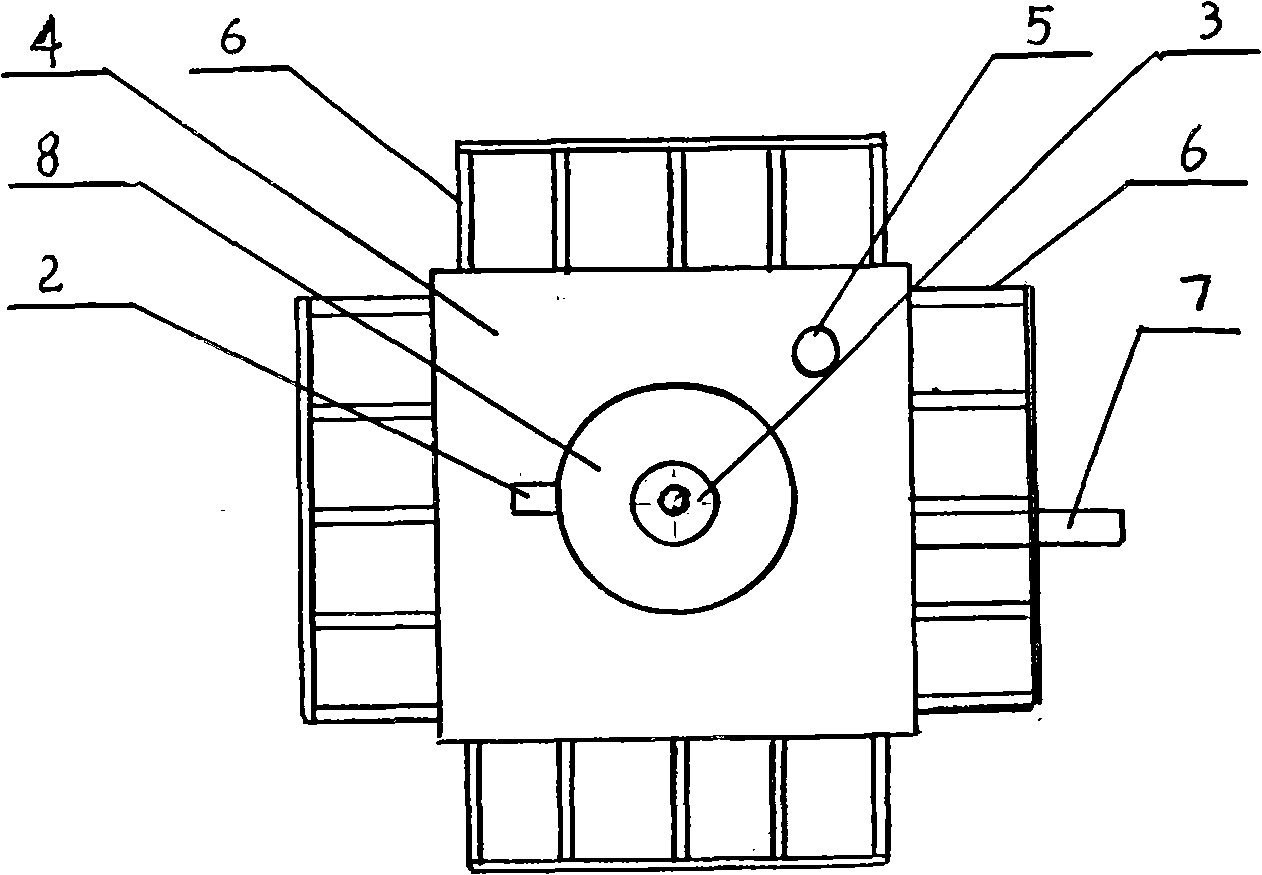

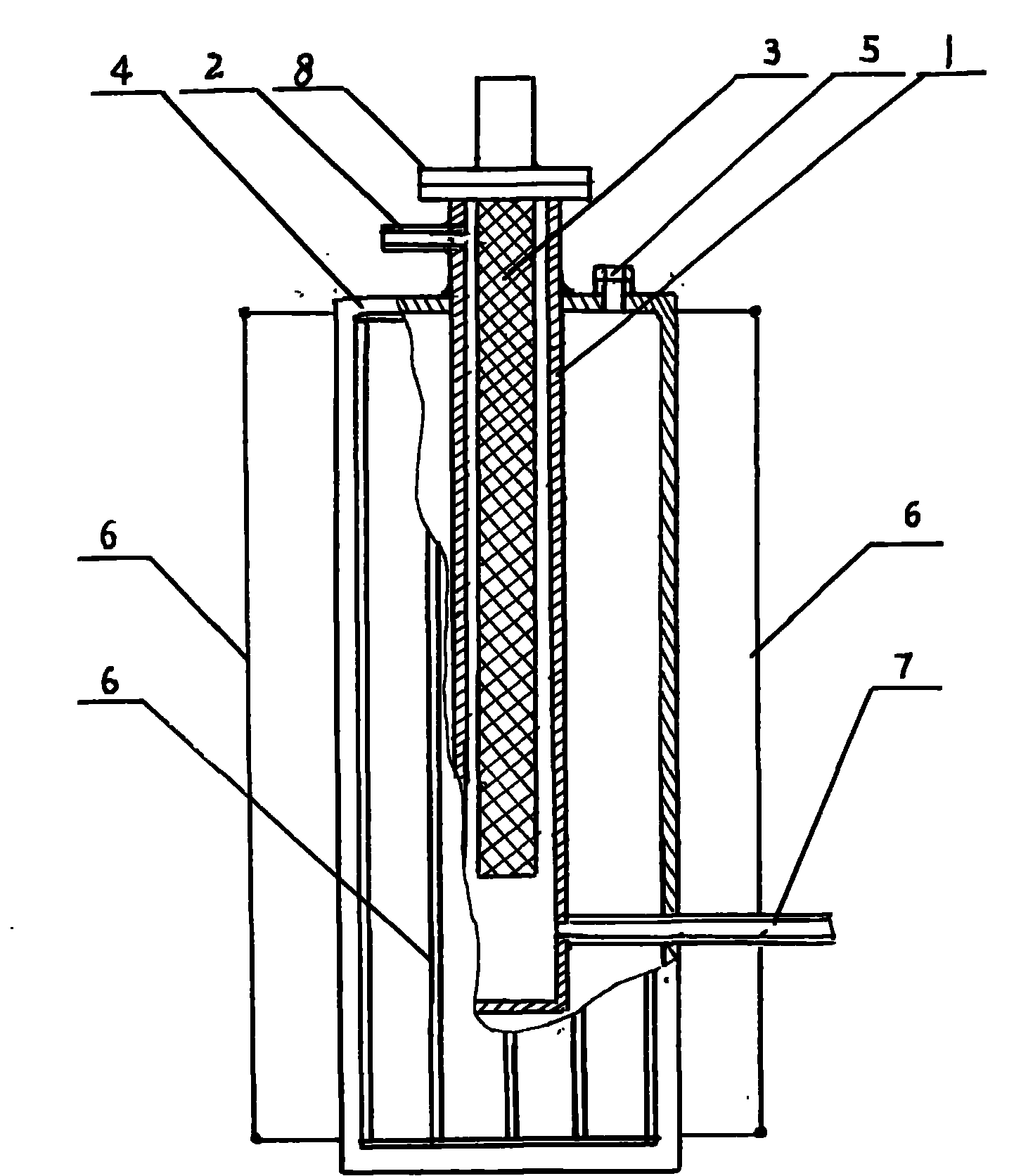

[0014] Example 1: see figure 1 and figure 2 Shown a kind of sodium hypochlorite generator electrolytic cell, comprise the electrolytic cell 1 that is cylindrical, be located at the chlorine outlet 2 of electrolytic cell upper end, be connected to the upper end of electrolytic cell by an insulator 8 and the bottom stretches in the electrolytic cell An anode electrode 3 in the shape of a cylindrical mesh; a cooling container 4 with a quadrangular cross section encloses the middle and lower part of the electrolytic cell, the top surface of the cooling container is located below the chlorine gas outlet 2, and the middle part of the top surface is welded to the upper part of the electrolytic cell In one body; cooling medium-water is housed in the cooling container, and a screw hole is provided on the top surface of the cooling container with a cathode electrode 5 of a screw-coordinated structure. Radiating fins 6 are provided on the side walls; an electrolyte delivery pipe 7 is a...

Embodiment 2

[0015] Embodiment two: see figure 1 and figure 2 , the electrolytic cell 1 of this example is cylindrical, and the upper end of the electrolytic cell is provided with a chlorine gas outlet 2, and the positive electrode 3 in the form of a cylindrical mesh is connected to the upper end of the electrolytic cell by an insulator and the lower part extends into the electrolytic cell. A cooling container 4 with a circular cross-section surrounds the middle and lower part of the electrolytic cell. The top surface of the cooling container is located below the chlorine gas outlet 2, and the middle part of the top surface is welded together with the upper part of the electrolytic cell; a cooling medium is installed in the cooling container -Transformer oil, the top surface of the cooling container is provided with a negative electrode 5 of a screw hole and a screw structure, the cooling medium-transformer oil is injected from the screw hole, and cooling fins are provided on the four sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com