Testing device suitable for measuring constant-pressure specific heat capacity of flow fluid

A technology of constant pressure specific heat capacity and experimental device, applied in the field of constant pressure specific heat capacity, can solve the problems of long residence time, large heat loss of flow heat transfer and radiation heat loss, lack of experimental data of constant pressure specific heat capacity of aviation kerosene, etc. Improve and reduce the effect of convective heat transfer heat loss and radiation heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

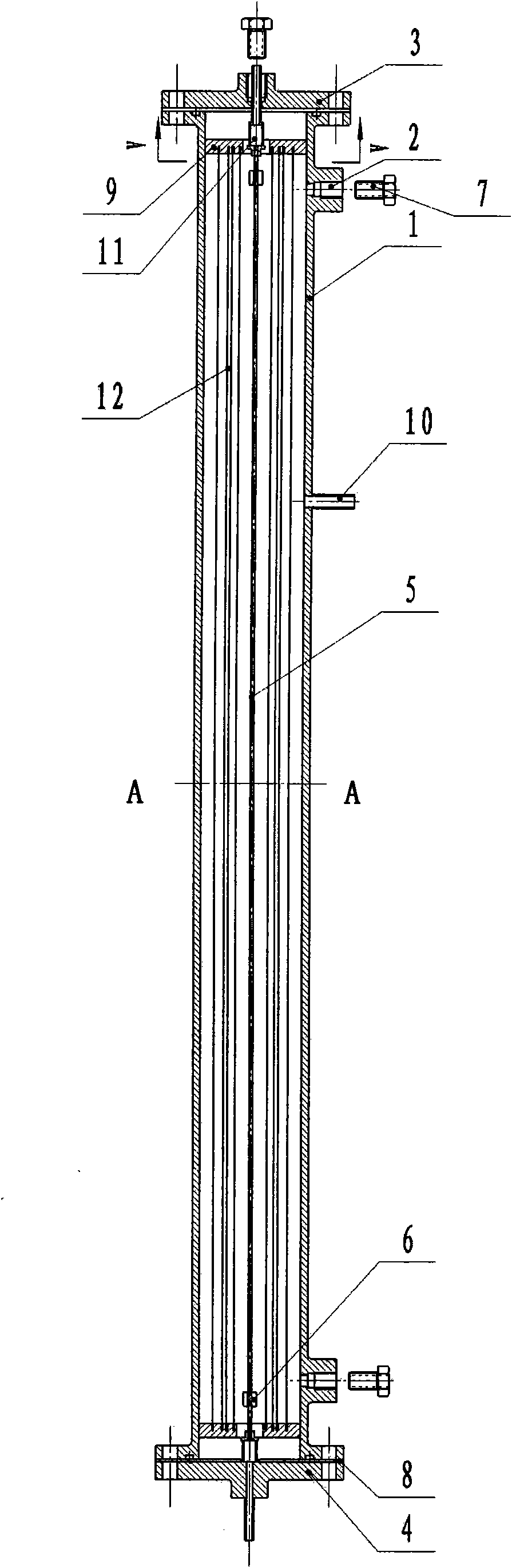

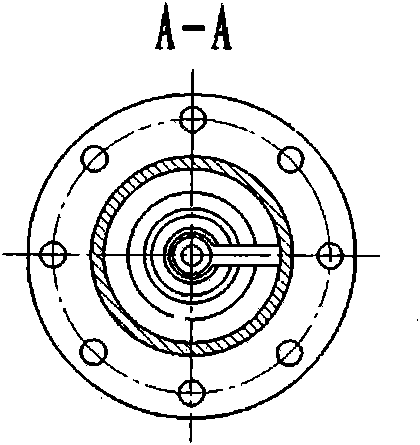

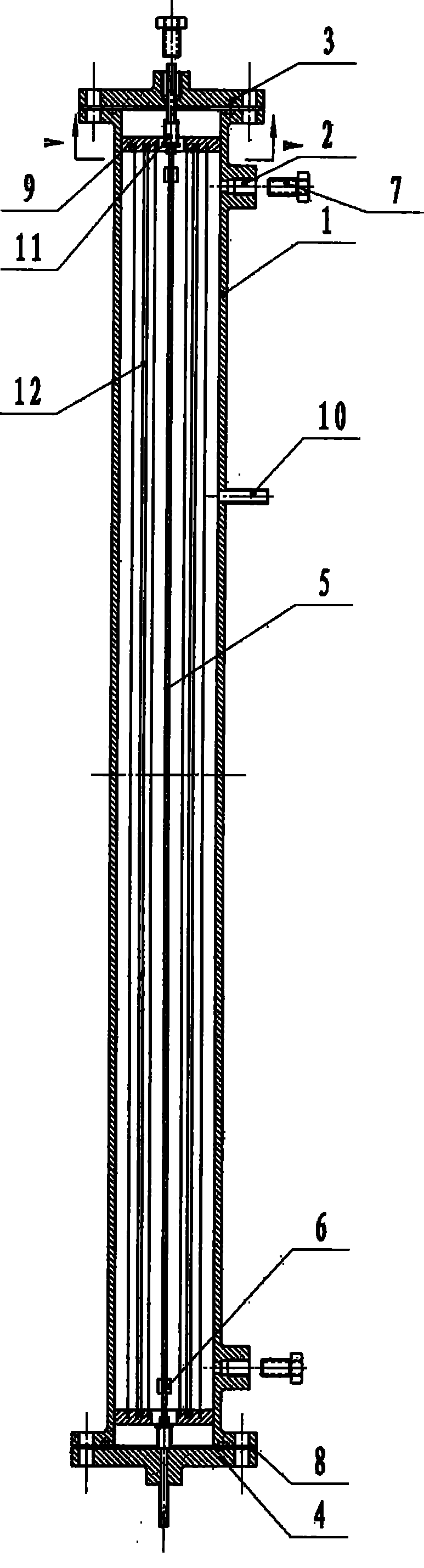

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings. see figure 1 shown. The experimental equipment includes a vacuum chamber, a heating part and a measuring part. The vacuum chamber includes a vacuum chamber shell (1), a low-temperature flange (3), and a high-temperature flange (4). The heating part includes an experimental heating tube (5) and a heating copper column ( 6), it is characterized in that: the fluid to be tested enters the experimental section from the low-temperature end of the stainless steel pipe (5), and a heating copper column (6) is welded by silver welding at about 10mm at both ends of the experimental heating pipe (6), Power supply, using the tube resistance of the stainless steel tube itself for electric heating, flowing out of the test section from the high temperature end, the measurement part includes a fluid pressure measuring device, a heating tube electric heating power measuring dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com