Composite specific heat measuring device by black body method

A technology of specific heat and black body, which is applied in the field of specific heat measurement device by composite black body method, can solve the problems of difference in absorption rate, large error of specific heat test, increase of experiment cost, etc., and achieve improvement of accuracy and reliability, accuracy and reliability , Improve the effect of accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

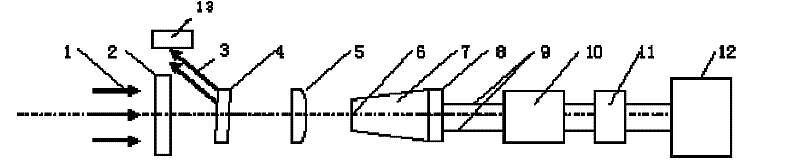

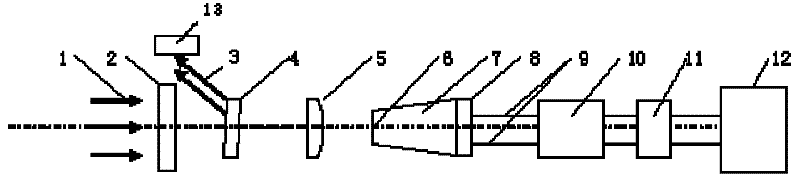

[0015] Combine below figure 1 The present invention will be further described with specific embodiments.

[0016] see figure 1 A variable aperture 2 is provided behind the irradiation end of the laser light source 1, and a beam splitter 4 is arranged behind the variable aperture 2, and a laser energy sensor 13 that can enter the laser energy after the beam splitting by the beam splitter 4 is set correspondingly to the beam splitter 4 , the beam splitter 4 is provided with a focusing lens 5, the rear end of the housing 7 with the energy sensor has a sample 8, and the front end is provided with a small hole 6 at the top of the housing that is convenient for the laser to enter and irradiate the sample 8, and the sample 8 is provided with a temperature sensor. Sensor 9, the first channel of the three-channel amplifier 10 is electrically connected to the temperature sensor 9, the second channel is electrically connected to the energy sensor of the housing 7 having the energy senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com