Capacitive voltage divider formed by a printed circuit board

A technology for printed circuit boards and capacitive voltage dividers, applied in the direction of voltage dividers, etc., can solve the problems of adverse effects on response speed, low measurement bandwidth of voltage dividing ratio of capacitive voltage dividers, and large coaxial structure volume, etc., to achieve easy processing , Good parasitic inductance, the effect of large capacitance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

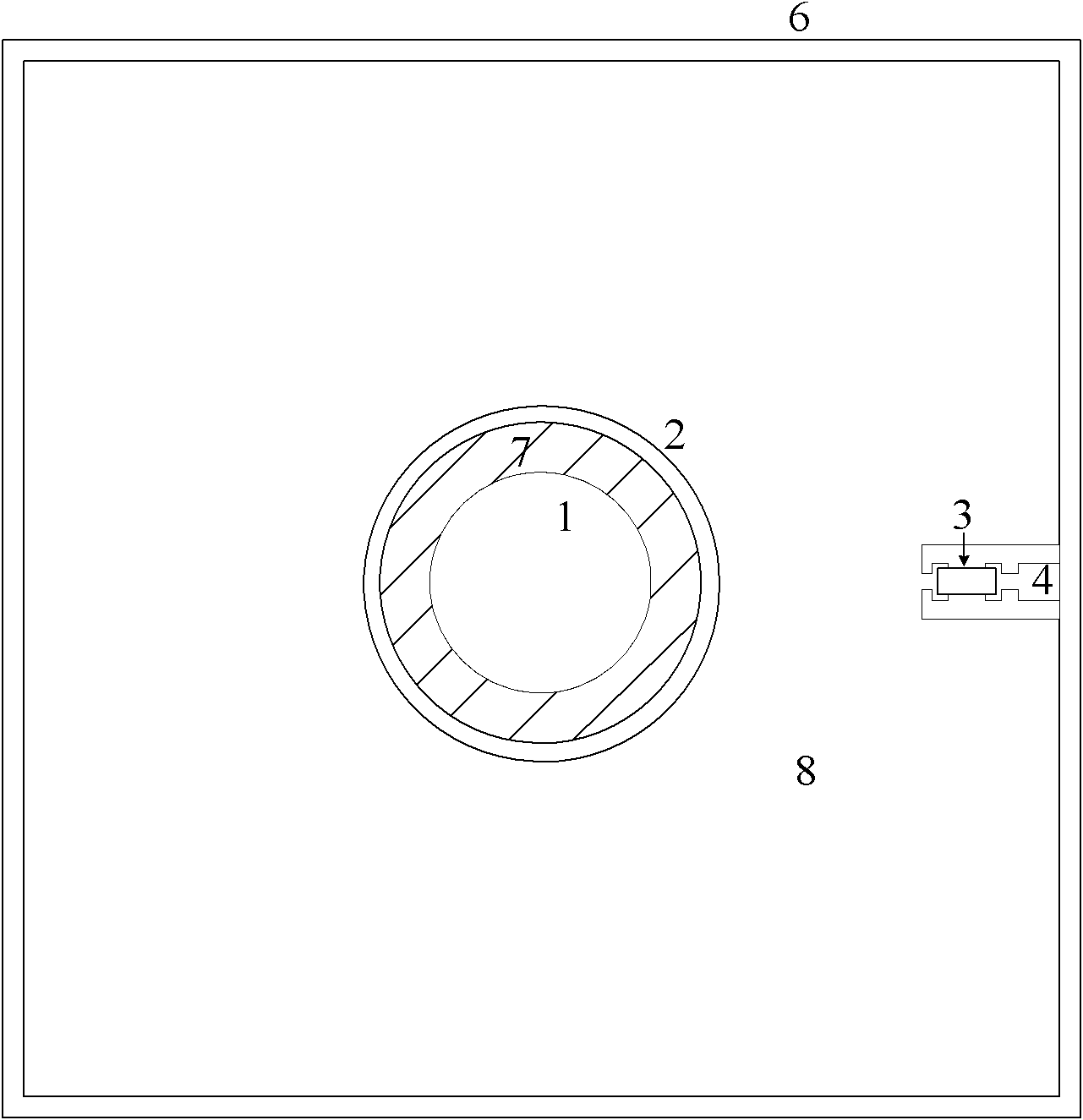

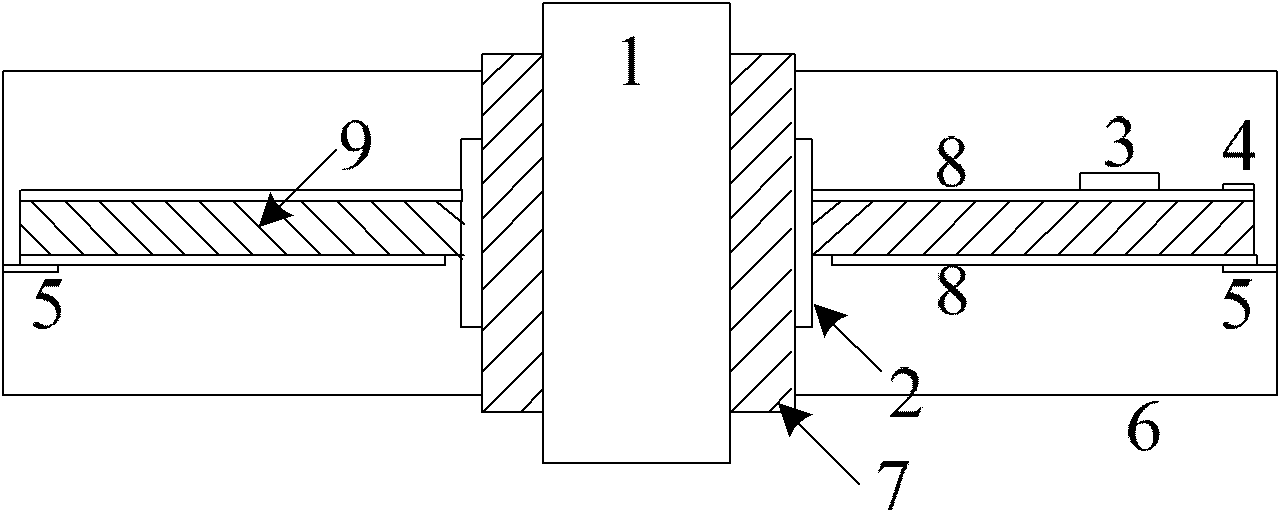

[0011] Embodiment 1: see figure 1 , 2. The present invention includes a grounding shell 6 and a high-voltage side bus bar 1 arranged in the grounding shell 6. An epoxy resin insulating part 7 is arranged between the high-voltage side bus bar 1 and the grounding shell 6, and the epoxy resin insulating part 7 The upper sleeve is equipped with a high-voltage implant electrode 2, and the high-voltage implant electrode 2 is equipped with a low-voltage arm of a capacitive voltage divider made of a double-layer printed circuit board. The low-voltage arm is composed of a base material 9 and printed on the base material. The surface is composed of a copper clad layer 8, the copper clad layer on one side is connected to the high voltage implanted electrode 2, and the ground terminal 5 connected to the ground shell 6 is arranged on the other side in four directions, and the capacitance of the low voltage arm Determined by the interlayer capacitance of the printed circuit board, the match...

Embodiment 2

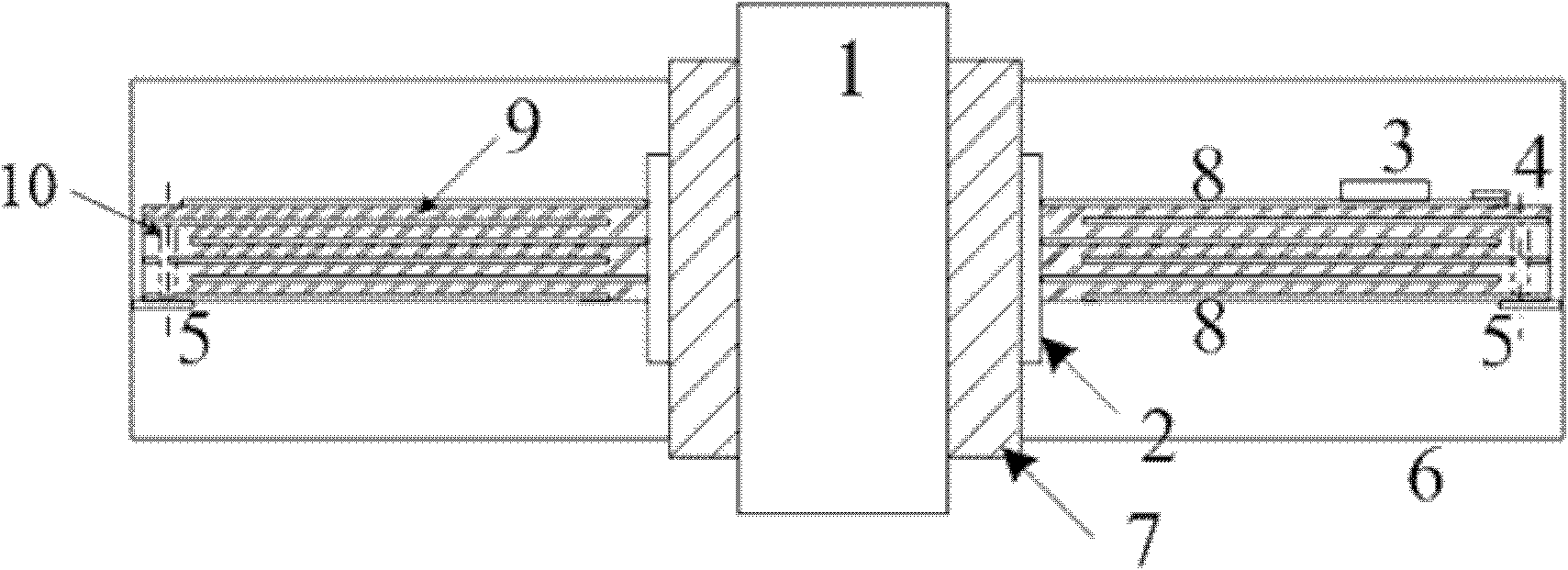

[0012] Example 2, see figure 1 , 3. In this example, when a multi-layer printed circuit board is used to form a low-voltage arm capacitor, the copper clad layers of the circuit board are divided into two groups, and the copper clad layers of different groups are isolated from each other, and the copper clad layers of the same group are connected by vias 10 , the two groups of copper clad layers are respectively connected to the voltage divider high-voltage implanted electrode 2 and the ground terminal 5 . Other connections are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com