Spinneret plate, preparation method of profiled filament processed by utilizing same

A spinneret and fiber technology, applied in the field of special-shaped fibers and their preparation, to achieve the effects of easy batch processing, novel shape and good gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

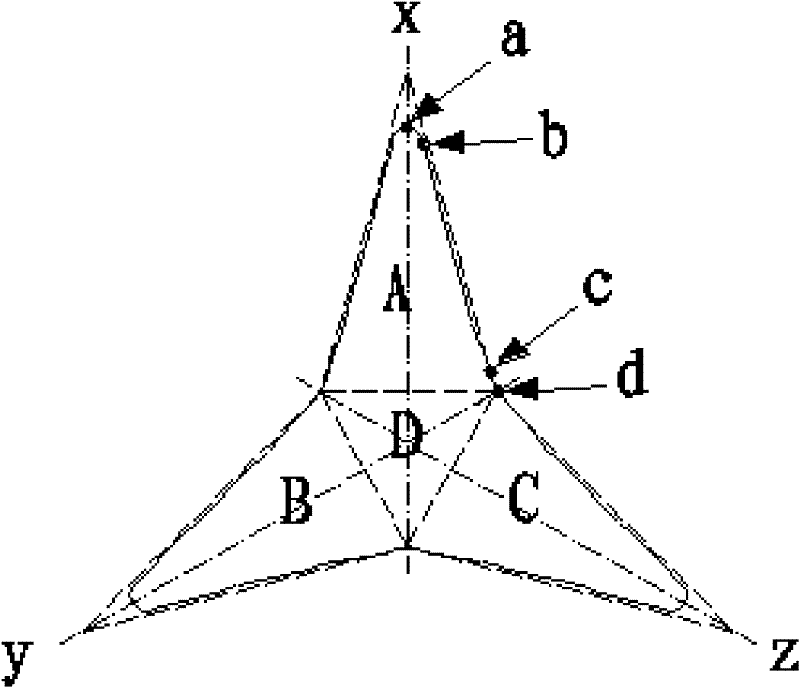

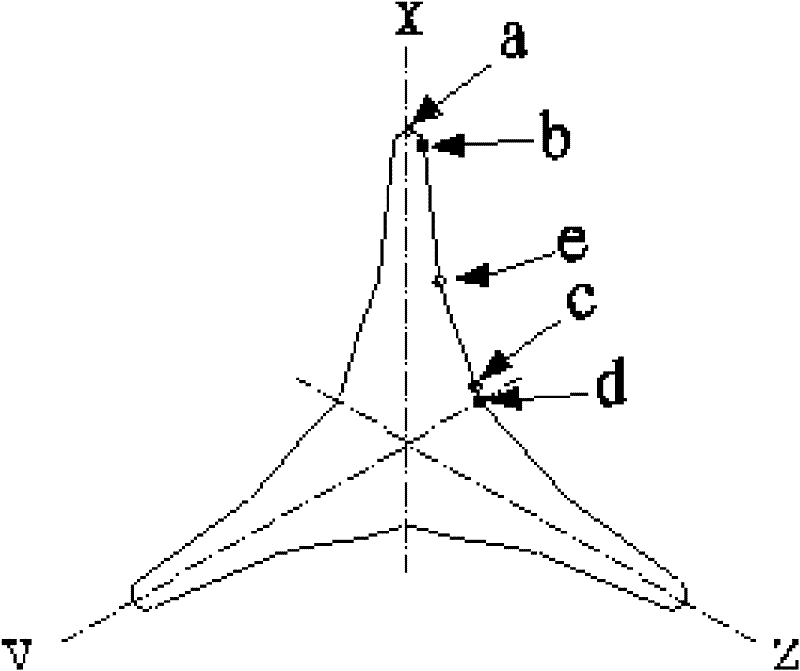

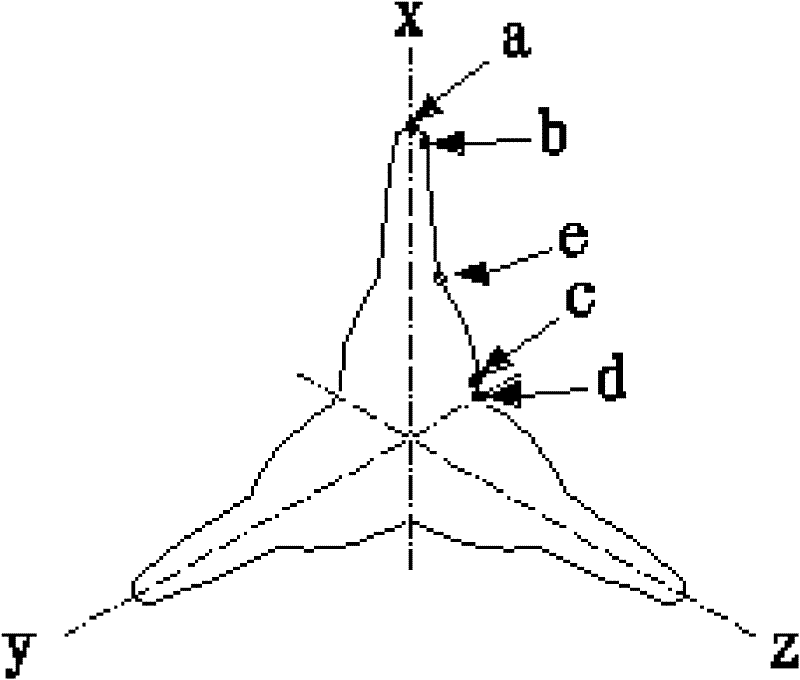

[0072] The spinneret hole size used was the data shown in Table 1a. The melt direct spinning equipment is used, the raw material is PET, the spinning process parameters are shown in Table 1b, and the properties of the fibers are shown in Table 1c. Both the spinneret hole and the spinning process have adopted the conditions in the invention, and the fiber shape and performance have reached the conditions in the invention.

[0073] Table 1a. Spinning hole size of Example 1

[0074] project parameter The angle between the waist and height of A or B or C 15° bc line Connecting two straight lines

[0075] The spinning process parameter of table 1b. embodiment 1

[0076] condition parameter Spinning temperature °C 292 Spinning speed m / min 2850 Number of spinneret holes 96 blowing method Outer ring blowing

[0077] Table 1c. Properties of Fibers of Example 1

[0078] index result Linear...

Embodiment 2

[0080] The spinneret hole size used is the data shown in Table 2a. The melt direct spinning equipment is used, the raw material is PET, the spinning process parameters are shown in Table 2b, and the properties of the fibers are shown in Table 2c. Both the spinneret hole and the spinning process have adopted the conditions in the invention, and the fiber shape and performance have reached the conditions in the invention.

[0081] Table 2a. Spinning hole size of Example 2

[0082] project parameter The angle between the waist and height of A or B or C 5° bc line Connecting two straight lines

[0083] Table 2b. The spinning process parameters of Example 2

[0084] condition parameter Spinning temperature °C 298 Spinning speed m / min 3000 Number of spinneret holes 72 blowing method Outer ring blowing

[0085] Table 2c. Properties of Example 2 fibers

[0086] index result Linear densit...

Embodiment 3

[0088] The spinneret hole size used is the data shown in Table 3a. The melt direct spinning equipment is used, the raw material is PET, the spinning process parameters are shown in Table 3b, and the properties of the fibers are shown in Table 3c. Both the spinneret hole and the spinning process have adopted the conditions in the invention, and the fiber shape and performance have reached the conditions in the invention.

[0089] Table 3a. Spinning hole size of Example 3

[0090] project parameter The angle between the waist and height of A or B or C 25° bc line Connecting two arcs

[0091] The spinning process parameter of table 3b. embodiment 3

[0092] condition parameter Spinning temperature °C 284 Spinning speed m / min 2860 Number of spinneret holes 72 blowing method Outer ring blowing

[0093] Table 3c. Properties of Example 3 fibers

[0094] index result Linear density / dtex ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com